Railway tunnel limit detection method

A detection method and tunnel technology, which is applied in the direction of railway vehicle profile measuring devices, railway car body parts, railway auxiliary equipment, etc., and can solve problems such as difficult operations, bulky tunnel limit detection devices, and unsuitable field operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

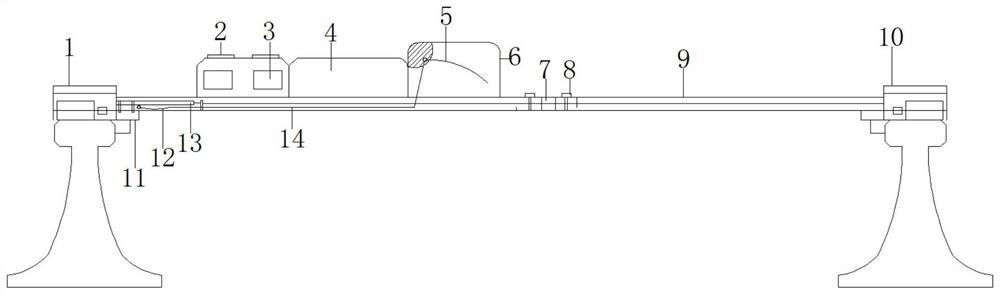

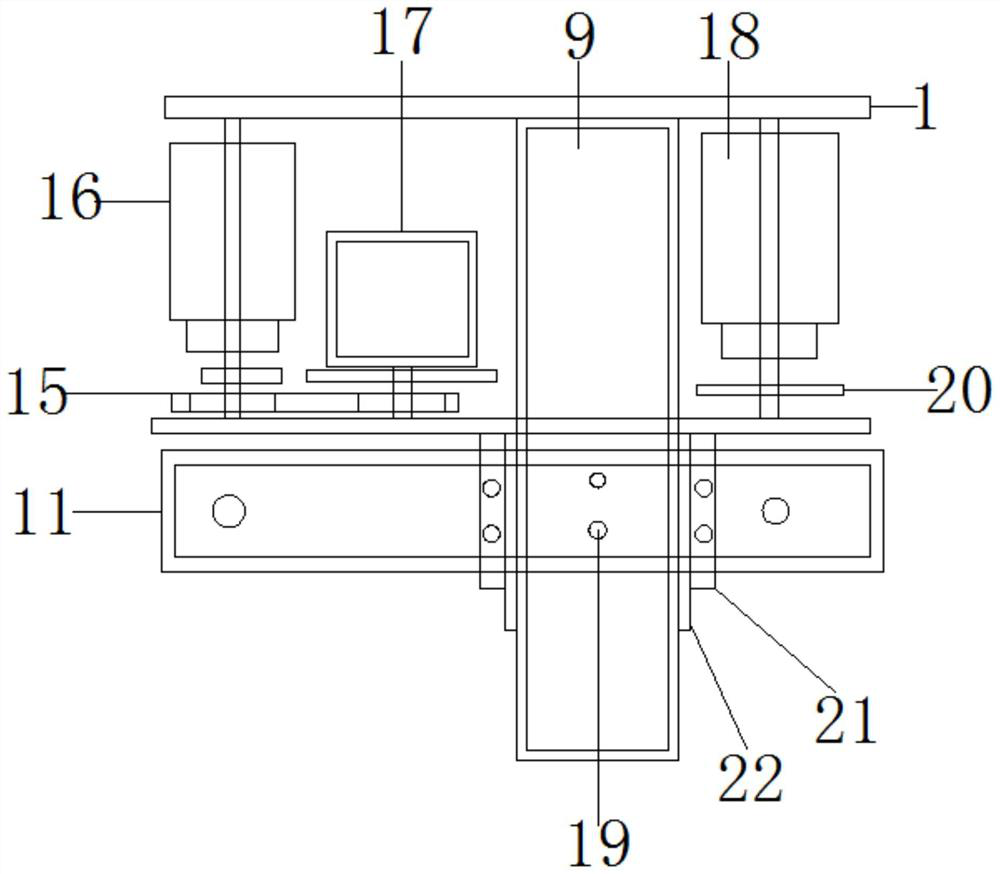

[0023] see figure 1 , 2 , a detection method for railway tunnel limits, comprising an integrated mobile mechanism 1 and an assembling movable mechanism 10, a detecting arm 9 is fixed between the integral moving mechanism 1 and the assembling movable mechanism 10 through a slot and a bolt, and the detecting arm 9 contacts Part of the folding shaft 7 is fixed by screws, and the folding shaft 7 is fixed by fixing bolts 8. There is a movable pulley frame 11 on the left side of the integrated moving mechanism 1, and the detection arm 9 is connected to the upper part of the movable pulley frame 11. The detection arm 9 and the movable pulley frame 11 Bolts a19 are fixed through threads, bolts b21 are provided on the front and rear sides of the detection arm 9, and guide rails 22 are provided between the bolts b21 and the detection arm 9, and the guide rails 22 are fixed on the movable pulley frame 11 by bolts b21, and the detection arm 9 Be provided with spring 12 between movable pu...

Embodiment 2

[0026] A method for detecting the boundary of a railway tunnel, comprising an integrated mobile mechanism 1, a management terminal 4, a boundary measuring instrument 2, and an assembleable mobile mechanism 10;

[0027] Methods as below:

[0028] S1: Install and fix the integrated mobile mechanism 1 and the assembled mobile mechanism 10 according to the tunnel data, fix the detection arm 9 through the folding shaft 7 and the fixing bolt 8, and perform the detection arm 9 and the integrated mobile mechanism through the movable pulley frame 11 and guide rail 22 1. After the connection with the movable mechanism 10 that can be assembled, after the fixing is completed, the above-mentioned device is installed. After the installation is completed, the initial work is completed;

[0029] S2: The gauge detection sensor detects the gauge according to the fixed position, the inclination sensor detects the inclination data, and transmits the data to the CPU and the control chip;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com