Screen frame positioning system suitable for treadmill printing machine

A positioning system and printing machine technology, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of increased production and processing costs, inconvenient adjustment, and the inconvenience of treadmill printing machines. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

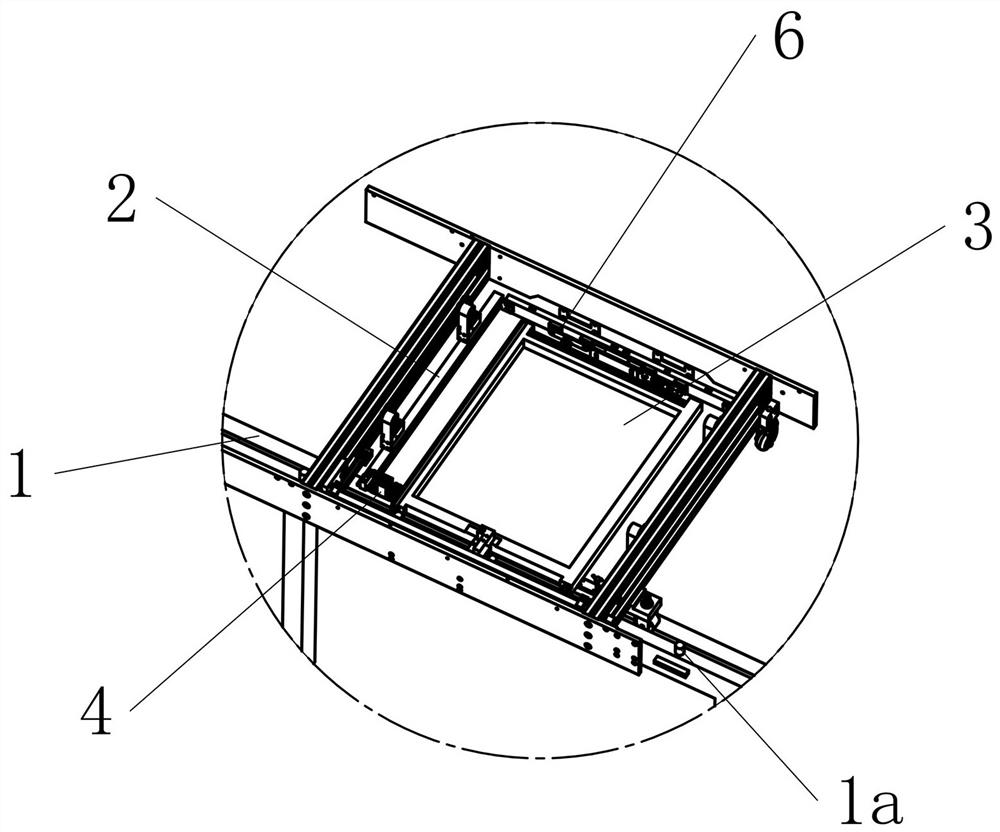

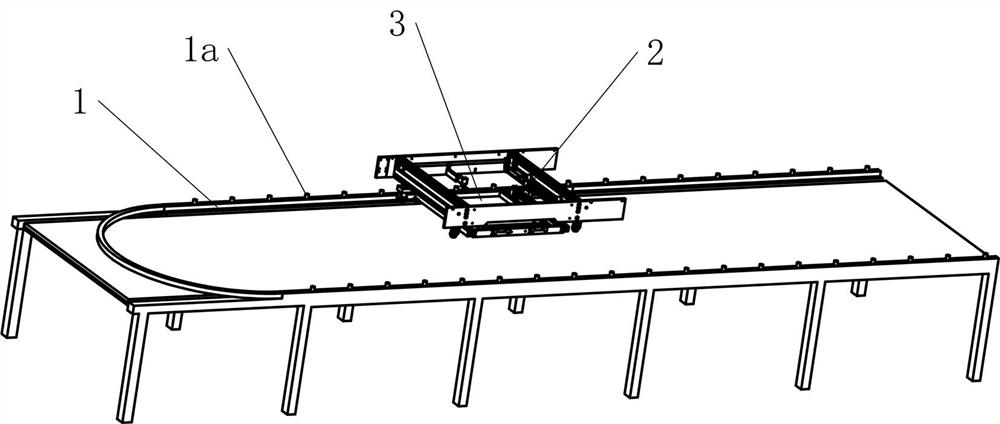

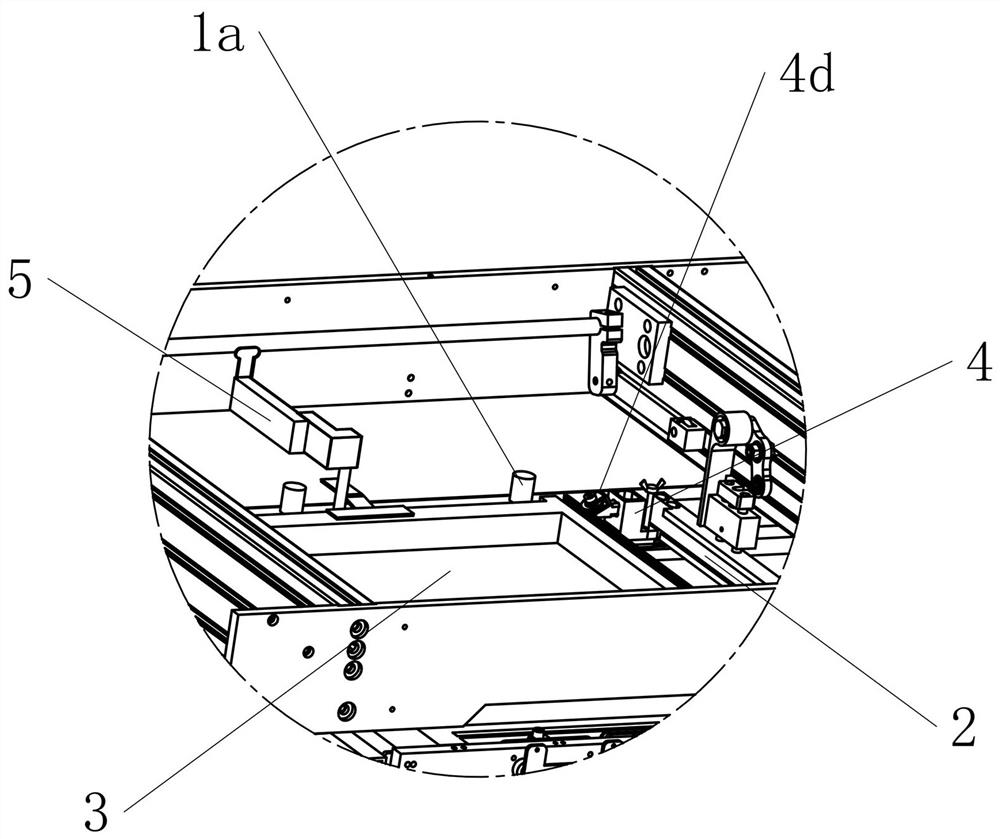

[0044] Embodiment 1: A screen frame guide rail positioning system suitable for a treadmill printing machine, including a guide rail 1 installed on the stand and extending along the X-axis direction for guiding the treadmill printing machine to walk. The upper surface of the guide rail 1 protrudes upwards to form several cylindrical positioning columns 1a, each positioning column 1a is arranged along the extending direction of the guide rail 1 and the adjacent two positioning columns 1a are spaced at the same distance, The positioning column 1a is installed and fixed in the X-axis direction and does not move any more. The walking system of the treadmill printing machine is fixedly installed with the guide rail 1 through the roller assembly clamped on both sides of the guide rail 1, and the driving wheel drives the printing machine to walk and move along the guide rail 1 on the platform surface. A net frame 2 for placing the screen frame 3 is movably installed on the treadmill p...

Embodiment 2

[0051] Embodiment 2: On the basis of Embodiment 1, the limit assembly 4d is integrated with the first positioning assembly 4, so that the first positioning assembly 4 includes a rotary roller whose rotation center axis is at a certain angle relative to the vertical direction 4e, the outer surface of the rotary roller 4e is a concave or convex arc-shaped curved surface, and the outer surface of the screen frame 3 used to abut against the outer surface of the rotary roller 4e is a corresponding convex or concave surface. Arc-shaped surface. At this time, the rotating roller 4e can provide the screen frame 3 with an abutting force horizontally along the X-axis direction and vertically along the Z-axis direction. At the same time, when the screen frame 3 moves along the Y-axis direction, the structure of the rotary roller 4e can effectively reduce the frictional resistance when the screen frame 3 moves through its own rotation, making the positioning process more efficient, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com