Negative pressure device and adsorption type robot

A negative pressure device and robot technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of easy air leakage at the joint between the wind resistance frame and the panel, insufficient adsorption pressure of the wind resistance frame, and large space occupation, etc., to achieve simple and convenient installation , Reduce the occupied space, the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

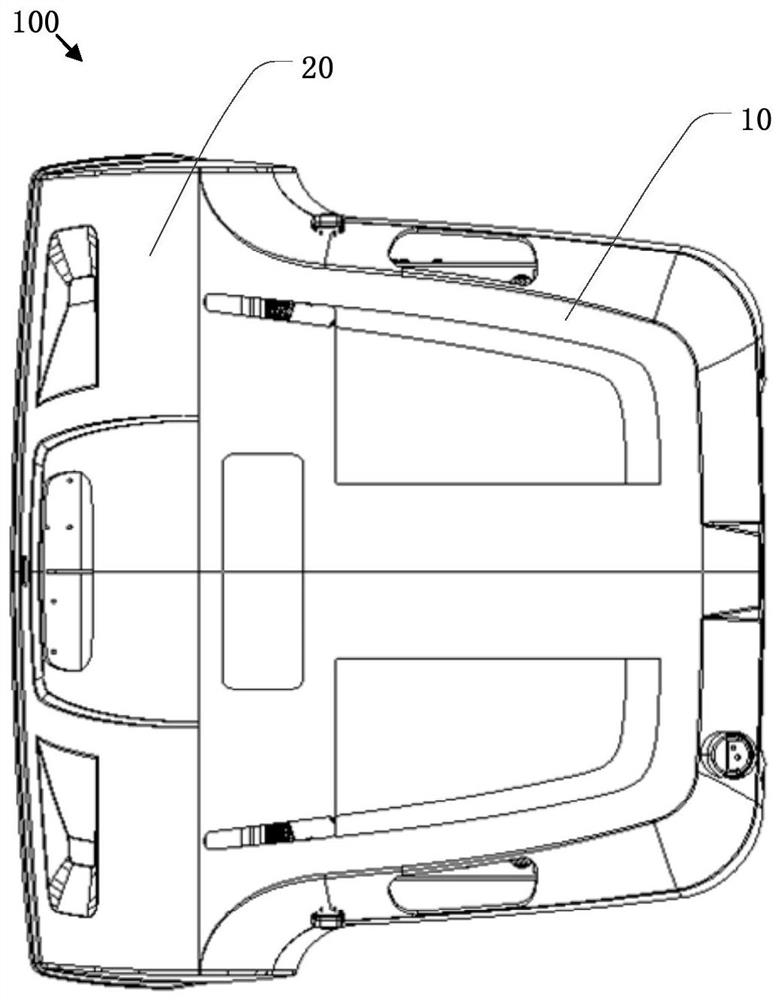

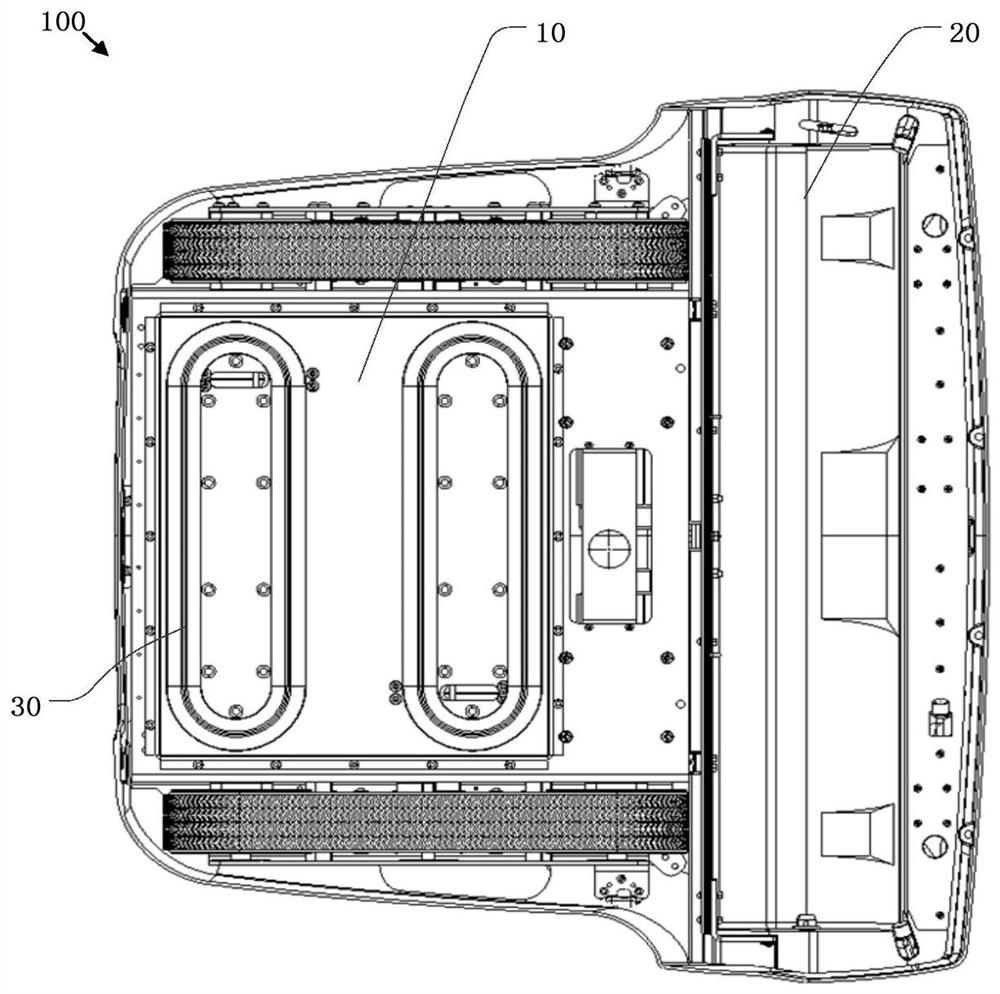

[0063] Such as figure 2 , image 3 , Figure 4 As shown, a kind of adsorption robot 100 (hereinafter referred to as robot) is provided in Embodiment 1. The adsorption robot 100 includes a car body 10, and the car body 10 can stably travel on a smooth plane arranged at an inclination. The smooth plane mentioned in the above is a photovoltaic panel (also called a solar panel) or a panel array composed of multiple photovoltaic panels for cleaning. In this embodiment, the inclination angle of the photovoltaic panel (that is, the angle between the photovoltaic panel and the horizontal plane) can be any angle value between 0-60 degrees, preferably between 30-40 degrees. The edge of each photovoltaic panel on the panel array is optionally provided with a frame, and there is a gap between any two adjacent photovoltaic panels, and the adsorption robot 100 has the ability to span the frame of the panel and the gap between the panels. In other embodiments, the smooth surface of the p...

Embodiment 2

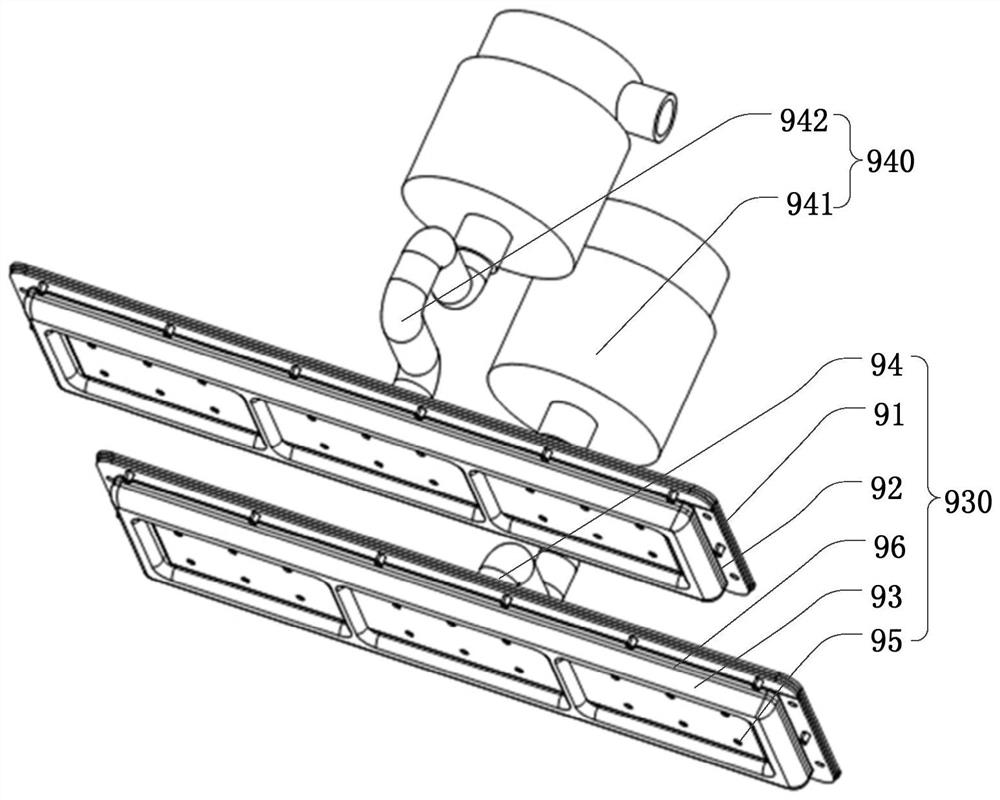

[0092] Such as Figure 14 As shown, embodiment 2 contains all the technical features of embodiment 1, and the difference is that, in order to further improve the adsorption effect, the adsorption device 30 in embodiment 2 also includes a pressure device 35 . The pressure device 35 is used to apply pressure to the wind resistance frame 32 in a direction away from the bottom plate 11 . Such as Figure 13 , Figure 14 , Figure 16 , Figure 17 , Figure 18 As shown, in this embodiment, one end of the pressure device 35 is connected to the bottom plate 11, and the other end is connected to the wind resistance frame 32, so as to press the wind resistance frame 32 downward, so that the wind resistance frame 32 is attached to the panel, and the pressure device 35 is The wind resistance frame 32 provides downward pressure, so that the wind resistance frame 32 fits to the upper surface of the photovoltaic panel as much as possible, and the elastic ring 34 on the lower surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com