Coal gangue screening equipment

A screening equipment and technology for coal gangue, which are applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of containing and affecting the quality of gangue particles, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

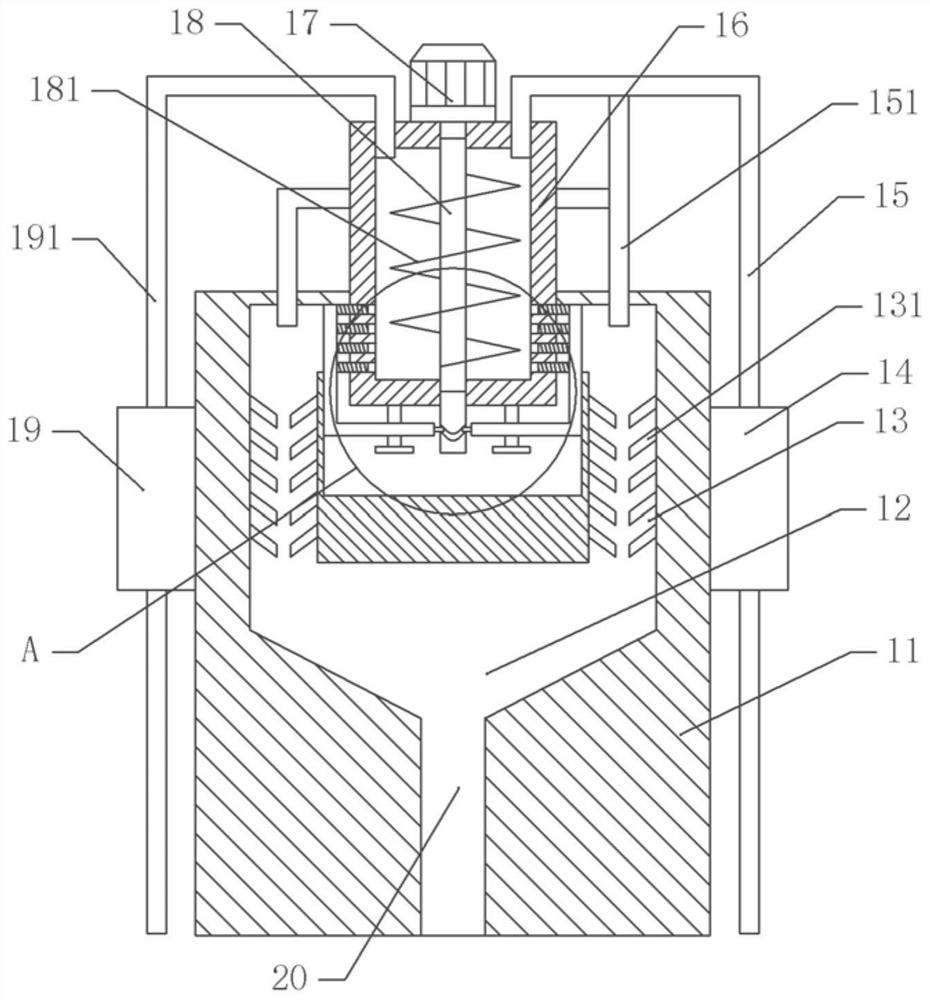

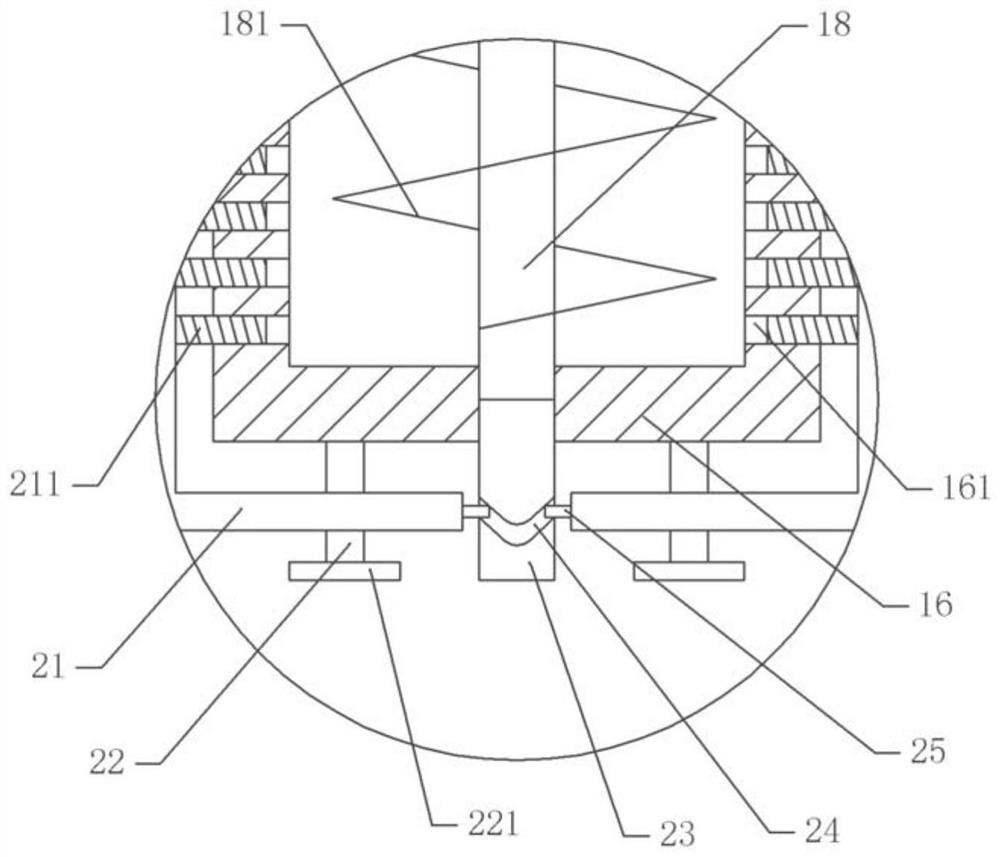

[0031] Basic as attached figure 1 And attached figure 2 Shown: a coal gangue screening equipment, including a frame, a body 11 is fixed by bolts on the frame, a screening barrel 16 is fixed by bolts on the upper part of the body 11, a first negative pressure machine 19 is fixed by bolts on the body 11, the first The inlet of the negative pressure fan 32 is connected with the material box, and the outlet of the first negative pressure fan 32 is connected with the feeding pipe 191 , and the feeding pipe 191 is connected with the screening barrel 16 . The sieving barrel 16 is provided with a stirring mechanism, the stirring mechanism includes a motor 17, the output shaft of the motor 17 is fixed with a stirring shaft 18 by coaxial bolts, the stirring shaft 18 is welded and fixed with stirring blades 181, the two sides of the sieving barrel 16 bottom There are several screening holes 161 on the wall, and the lower end of the stirring shaft 18 is fixed with a rotating shaft 23 by...

Embodiment 2

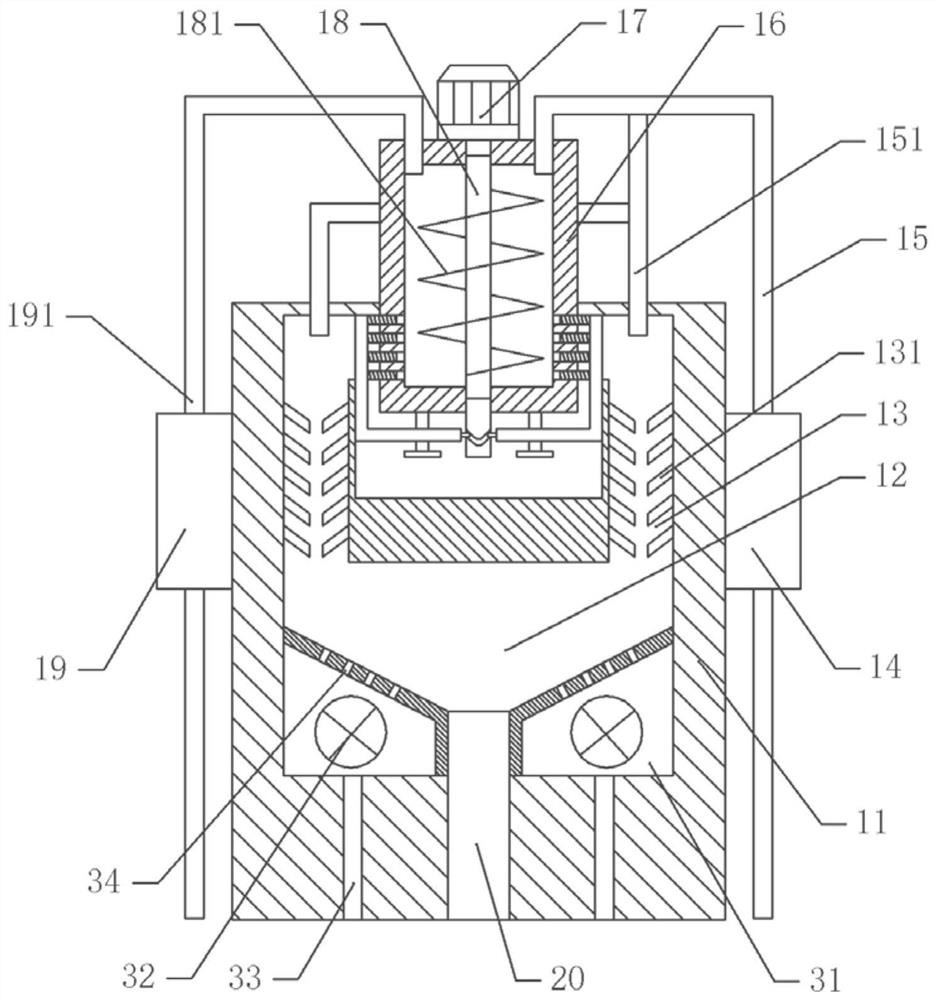

[0038] The difference between embodiment two and embodiment one is that, as attached image 3As shown, there are several dust removal chambers 31 on the body 11. Fans 32 bolted on the body 11 are arranged in the dust removal chambers 31. The fan 32 is an exhaust fan 32. There is an air hole 34 communicating with the collection chamber 12 , the air inlet of the fan 32 is in communication with the air passage 33 , and the air outlet of the fan 32 faces the air hole 34 .

[0039] When the fan 32 works, the fan 32 inhales the outside air through the air channel 33, and the fan 32 blows the gas into the collection chamber 12 through the air hole 34, and the gas flows to blow off the dust on the gangue particles, so that the dust on the gangue particles is reduced. , to further improve the quality of gangue particles. Under the effect of the dedusting mechanism, the gas flows upwards and blows off the dust on the gangue particles when passing through the discharge channel 13. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com