A method for treating arsenic in strongly acidic wastewater using cerium oxide adsorbent

An adsorbent, cerium oxide technology, applied in the fields of adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. High activity, high adsorption capacity, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

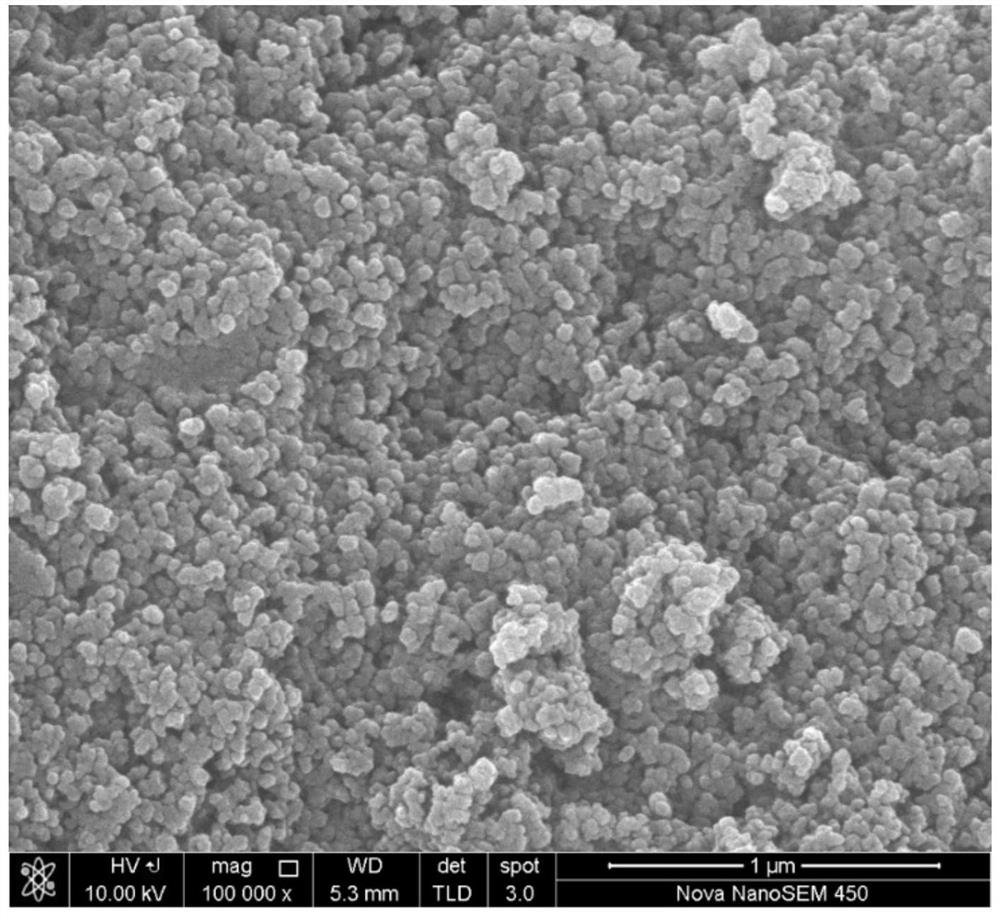

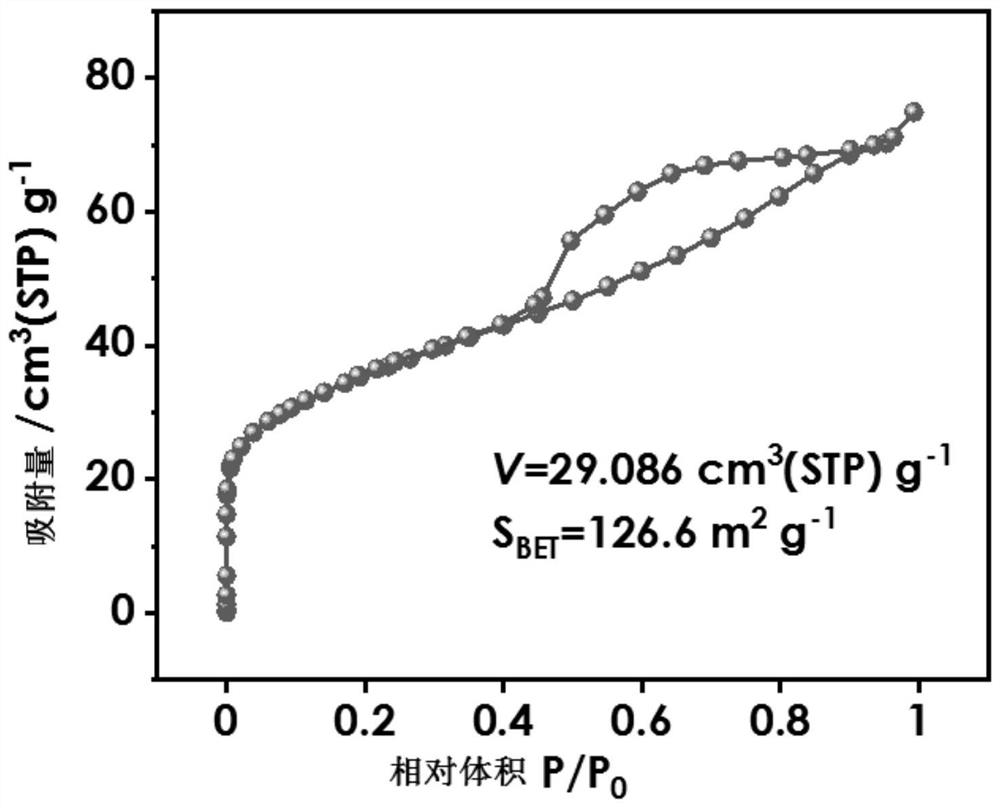

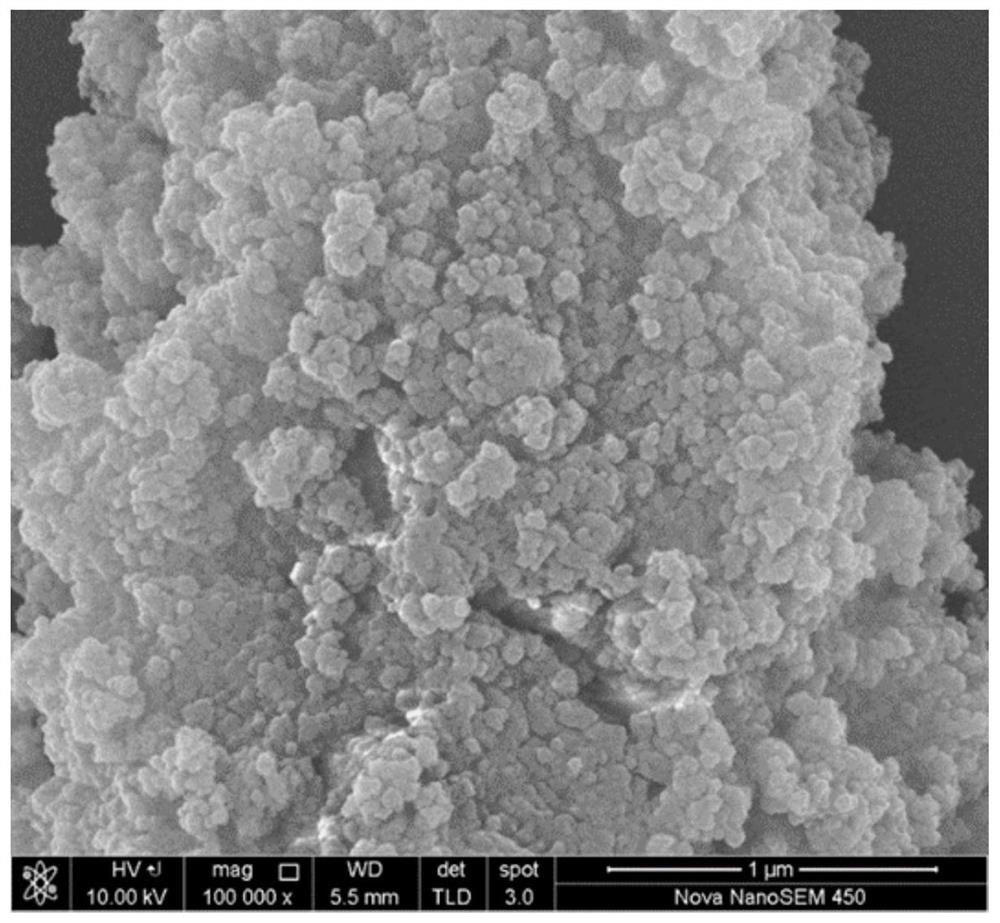

Image

Examples

specific Embodiment approach 1

[0032] Embodiment 1: This embodiment is a method for treating arsenic in strongly acidic waste water with cerium oxide adsorbent, which is specifically carried out according to the following steps:

[0033] Put the cerium oxide adsorbent into the waste water to be treated, and oscillate the adsorption in the constant temperature shaking shaker for 4h~12h, that is to complete the adsorption of arsenic;

[0034] The mass of described cerium oxide adsorbent and the volume ratio of waste water to be treated are 1mg:(1mL~2mL);

[0035] The concentration of arsenic in the wastewater to be treated is 1 mg / L to 300 mg / L, and the arsenic exists in the form of pentavalent arsenic and trivalent arsenic; the pH of the wastewater to be treated is -0.5 to 1;

[0036] The preparation method of described cerium oxide adsorbent is as follows:

[0037] 1. Dissolve sodium hydroxide solid powder in absolute ethanol, and stir ultrasonically for 0.5h to 1h to obtain NaOH-AE mixed solution;

[003...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 1, the sodium hydroxide solid powder is dissolved in absolute ethanol, and the NaOH-AE mixed solution is obtained after ultrasonic stirring for 0.5 h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the cerium oxide adsorbent is put into the waste water to be treated, and the arsenic adsorption is completed in a constant temperature oscillating shaker for 4 hours. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com