Preparation method of magnetic core of open-type mutual inductor and shaping outer mold structure applied by the same

A transformer and open-type technology, which is applied in the field of shaped external mold structure, can solve problems such as difficulty in cooperation, inability to deal with cracks on the end face of the magnetic core, and influence of material characteristics of the open-type transformer, achieving stable assembly and smooth end faces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

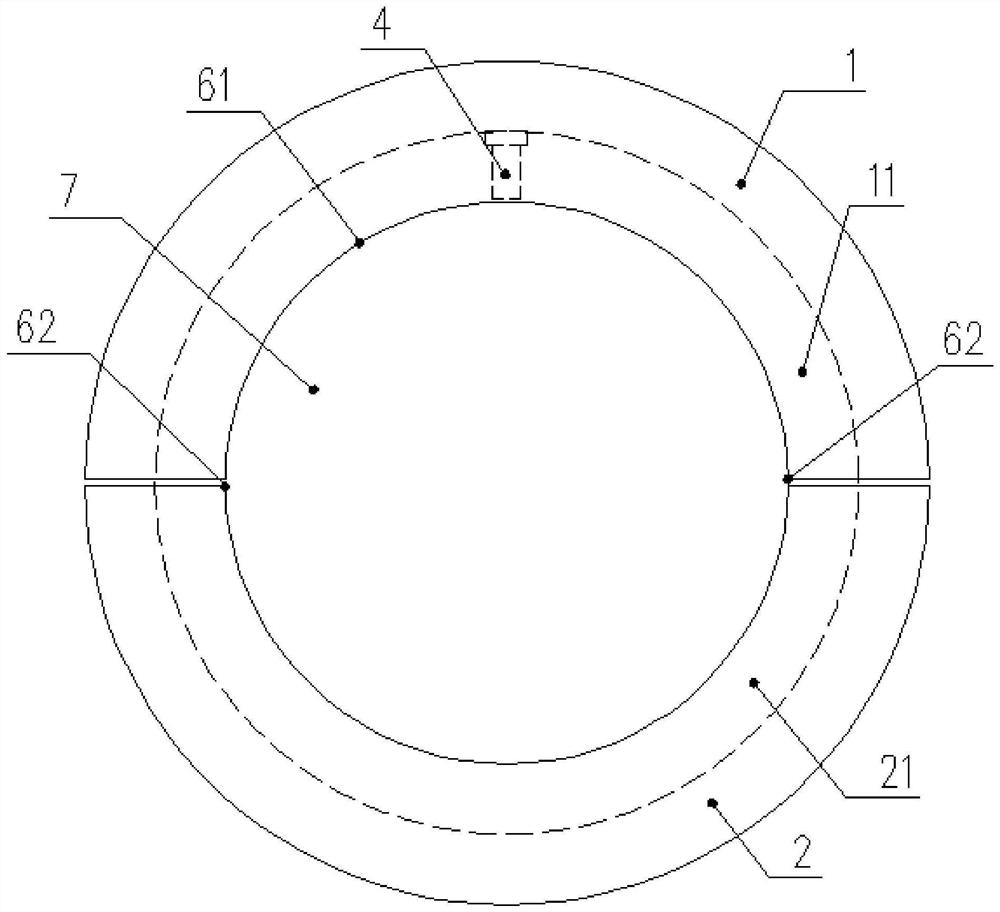

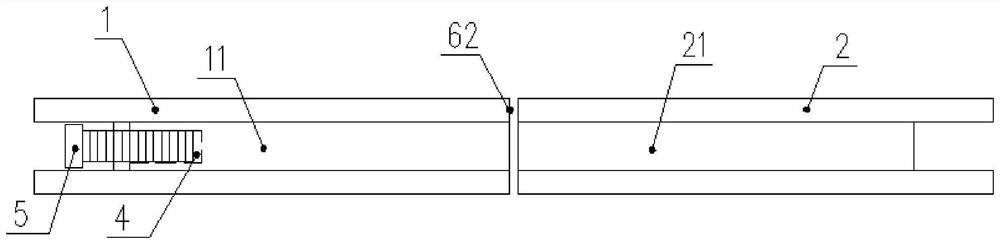

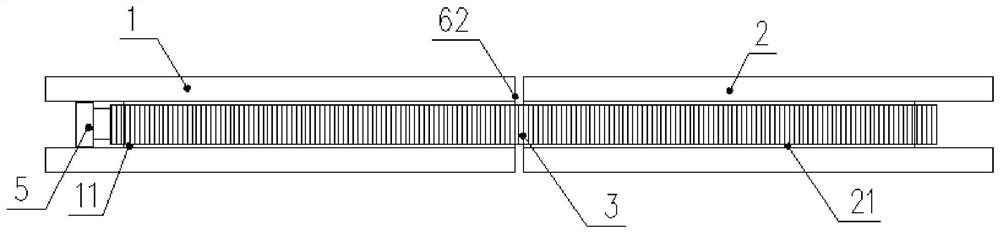

[0035] Such as Figure 1 to Figure 4 Shown, the magnetic core preparation method of a kind of open transformer of the present invention, it comprises the following steps:

[0036] S1. Select a suitable magnetic core material, and perform winding processing to obtain a circular magnetic core base block;

[0037] S2, performing heat treatment on the prepared magnetic core block;

[0038] S3. Carrying out varnish dipping treatment on the magnetic core block obtained by the heat treatment;

[0039] S4. Baking and curing the magnetic core base block obtained from the varnish dipping treatment, and performing molding treatment on the magnetic core base block during the baking process;

[0040] S5. Carry out cutting processing on the magnetic core base block ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com