A pipe cutting device for thick-walled pvc plastic pipes

A technology for plastic pipes and pipe cutting, applied in the direction of metal processing, etc., can solve the problems of easy fragmentation and dispersion, PVC ports cannot be put into practical use, etc., to achieve the effect of neat and smooth end face, improved safety performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

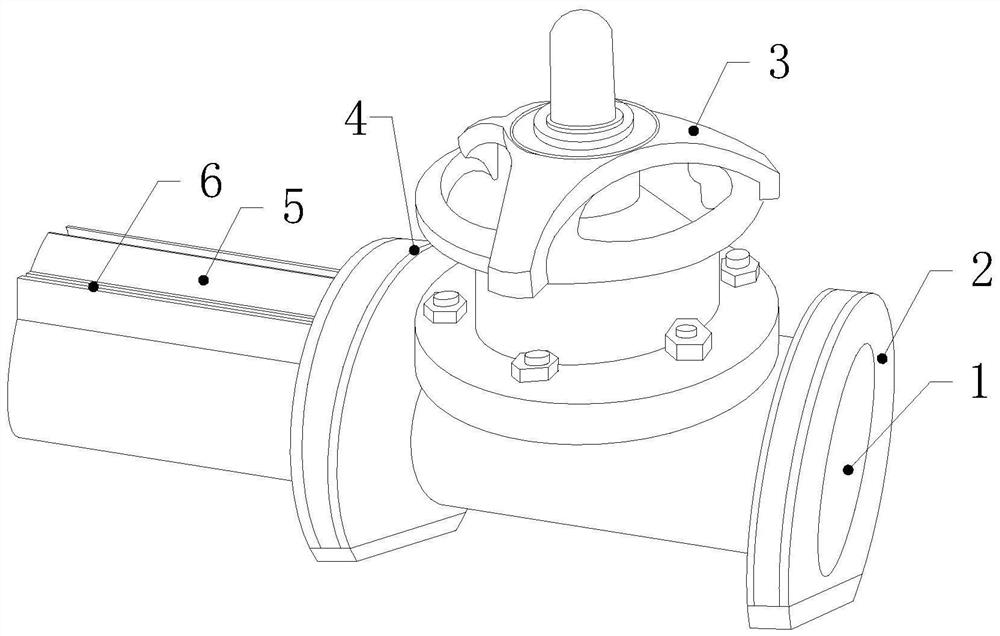

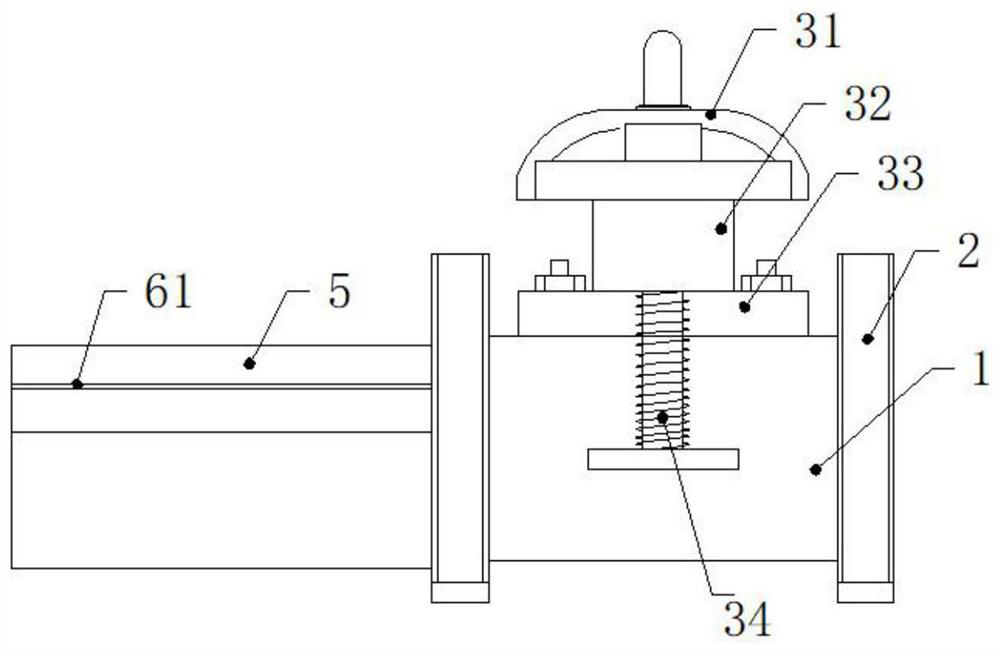

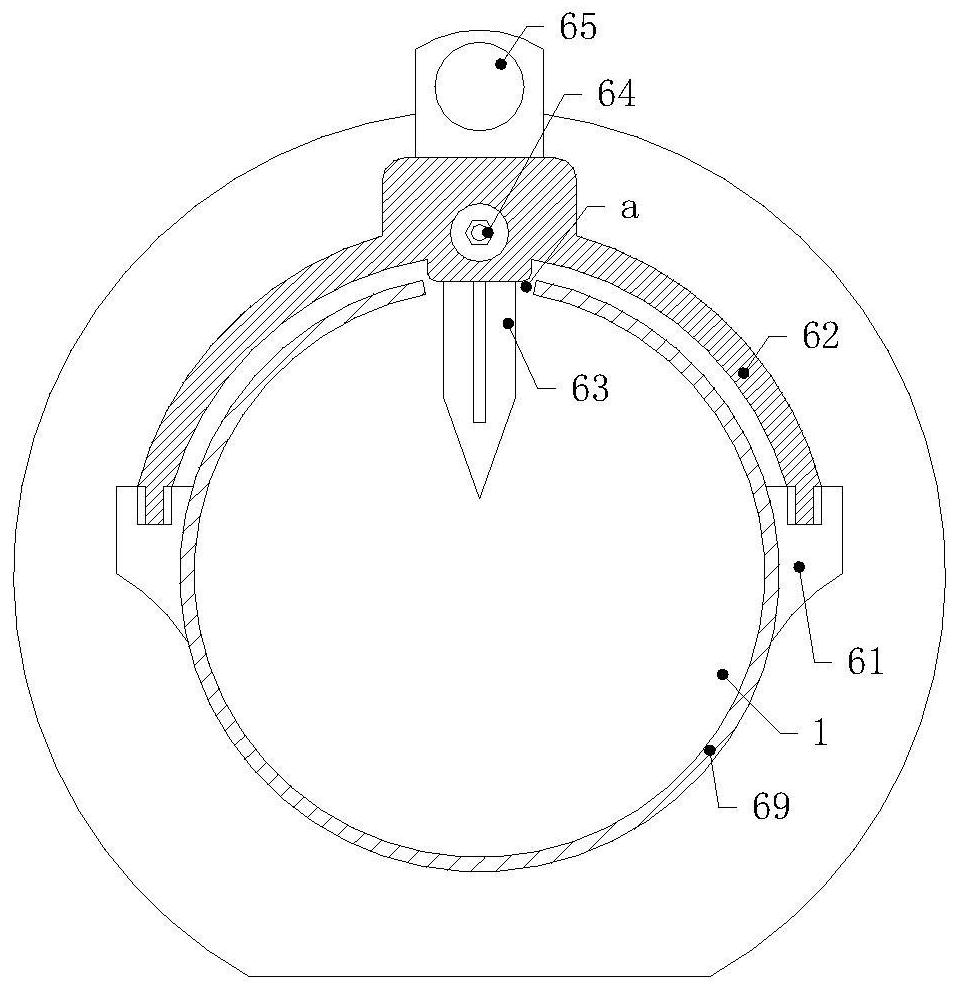

[0027] see Figure 1-Figure 6 , the present invention provides a thick-walled PVC plastic pipe cutting device, the structure of which includes a placing pipe 1, a first support 2, a screw pressing mechanism 3, a second support 4, a wrap-cut pipe 5, and a cutting structure 6. The horizontal ends of the placement tube 1 are respectively provided with a first support 2 and a second support 4, and the horizontal ends of the placement tube 1 are respectively vertically welded with a first support 2 and a second support 4. The placement tube 1. A screw press-down mechanism 3 is installed in the middle, and one end of the placement pipe 1 is horizontally connected with a circumscribed pipe 5. The diameter of the circumscribed pipe 5 is equal to the diameter of the placement pipe 1, and the top of the circumscribed pipe 5 is directly above. A cutting structure 6 is provided, and the cutting structure 6 is connected with the top end surface of the wrap-cutting pipe 5 by sliding.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com