Frictional wear life testing machine for self-lubricating joint bearing

A joint bearing, friction and wear technology, applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of insufficient automation, inconvenient bearing disassembly, inconvenient temperature sensor clamping, etc., to achieve Space saving, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

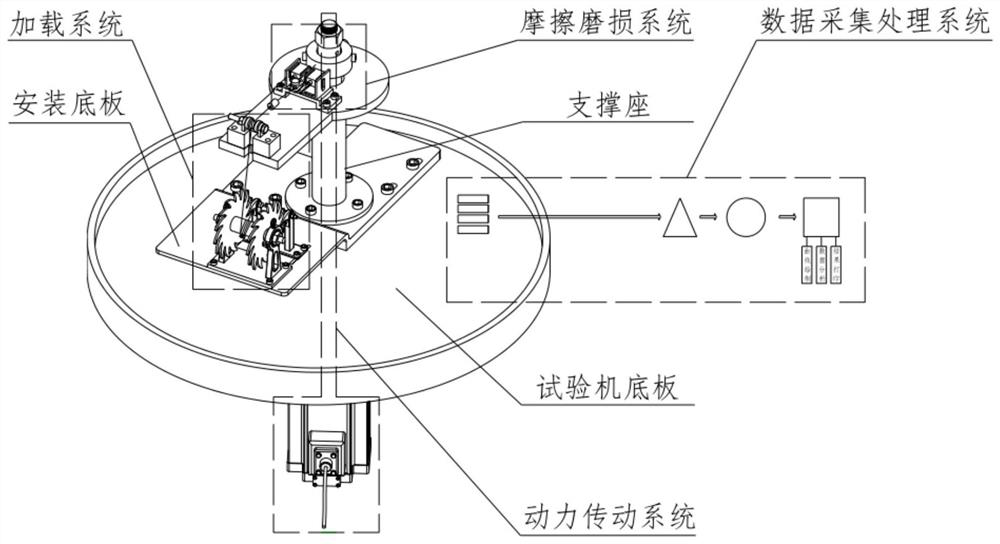

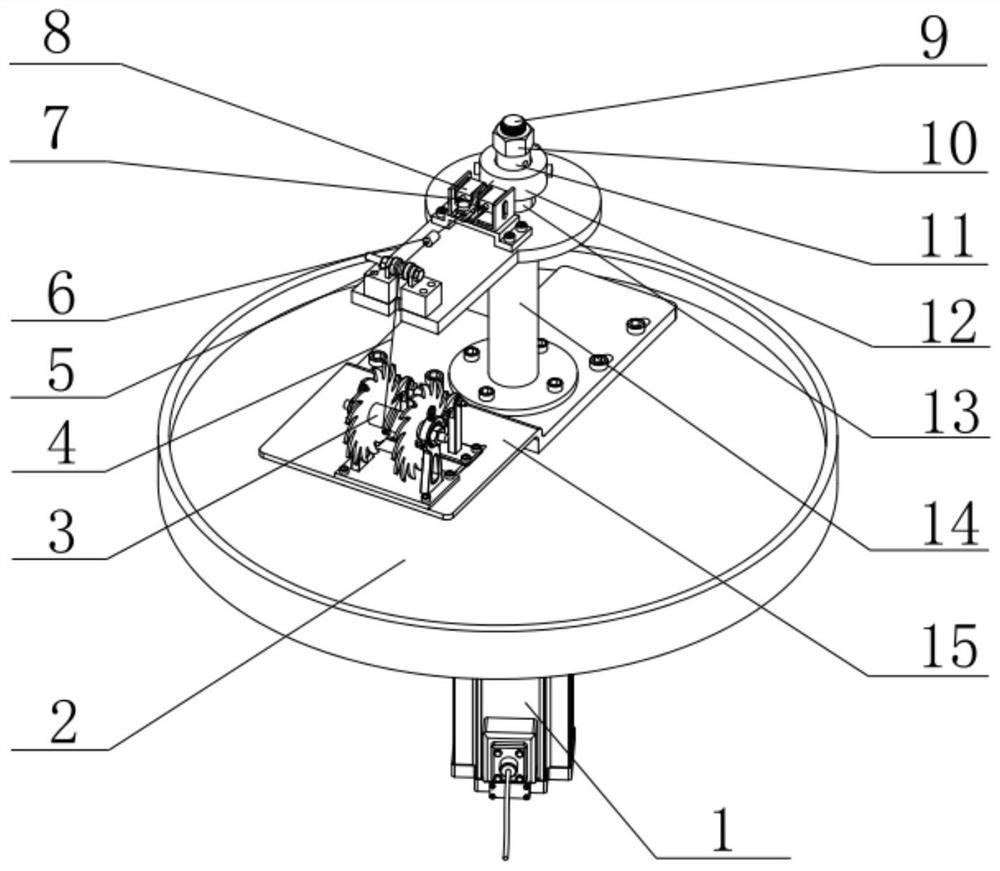

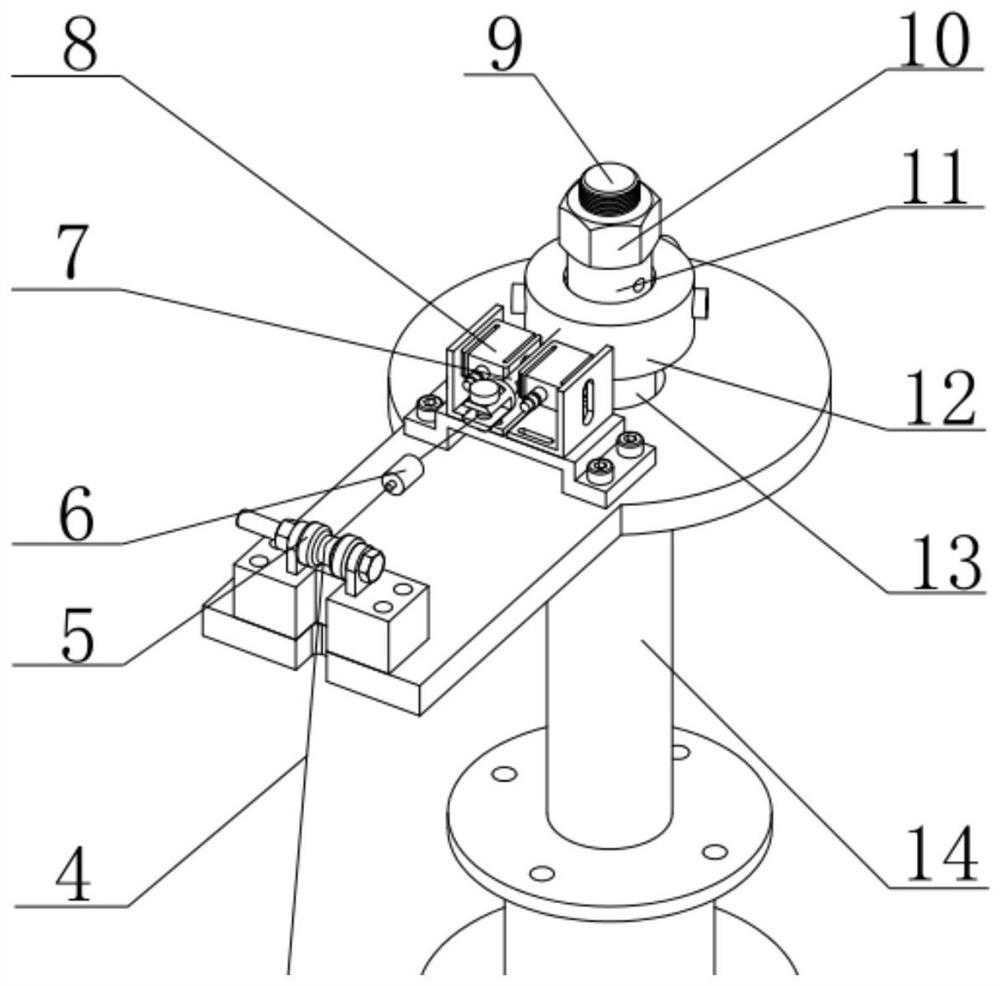

[0038] The structure of the self-lubricating joint bearing friction and wear life testing machine of the present invention is as follows: figure 1 As shown, it includes the testing machine bottom plate, the installation bottom plate, the support seat, the friction and wear system, the power transmission system, the loading system and the data acquisition and processing system; wherein, the power transmission system runs through the test machine bottom plate and the installation bottom plate from bottom to top; the support seat Set on the upper part of the power transmission system and fixed on the installation base; the friction and wear system is fixed on the top of the support base, the loading system is installed on the installation base, and the friction and wear system is connected to the loading system through a traction rope; the data acquisition and processing system is located next to the testing machine In the control cabinet, it is connected to the friction and wear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com