A kind of cable with high temperature resistance and long service life and its preparation method

A technology with high temperature resistance and long life, which is applied in the direction of cable/conductor manufacturing, power cables with shielding layer/conductive layer, power cables, etc. problems, to achieve simple and environmentally friendly production, reduce external interference, and facilitate preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

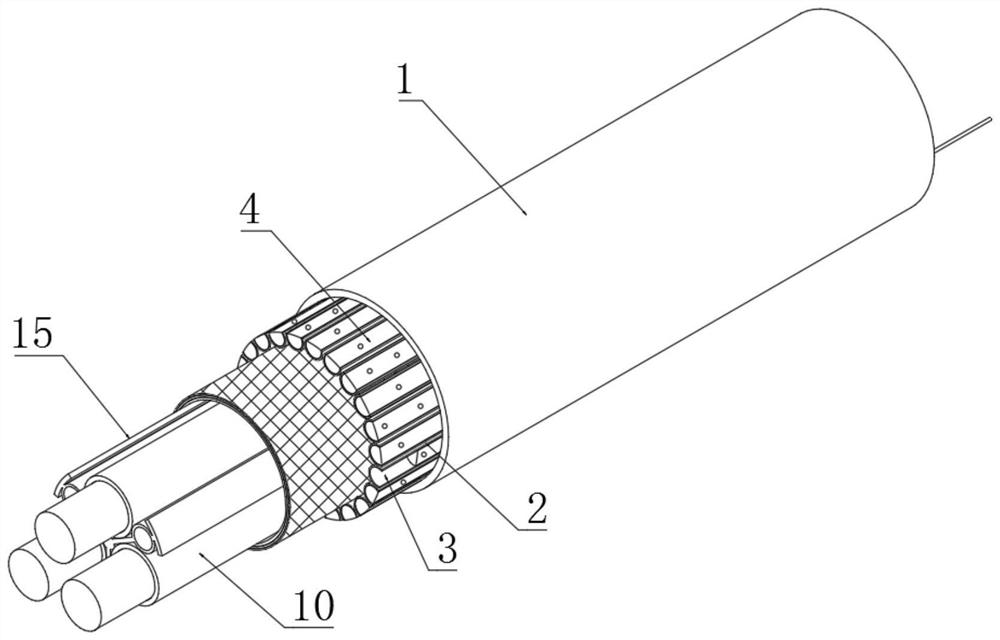

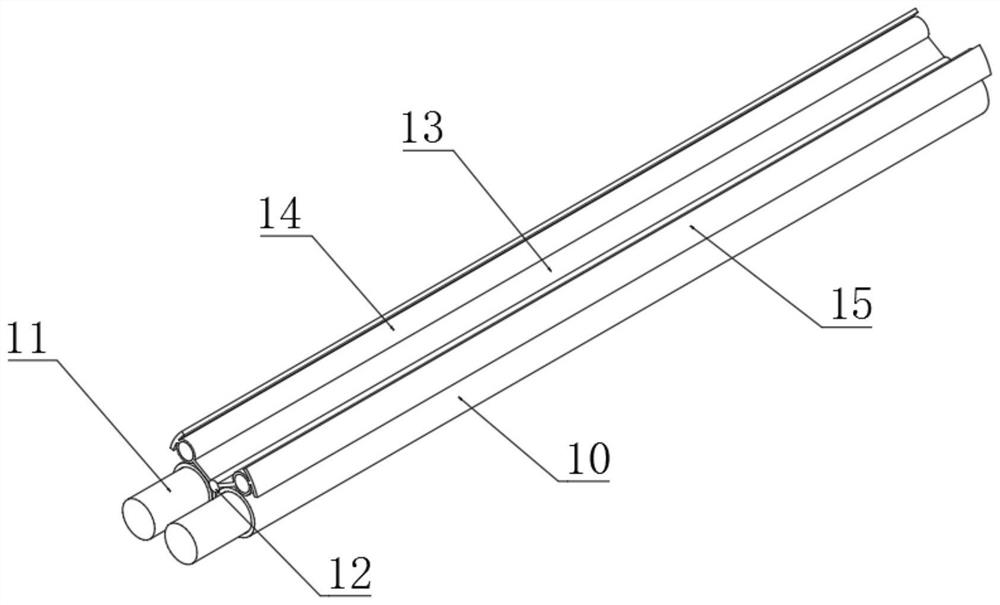

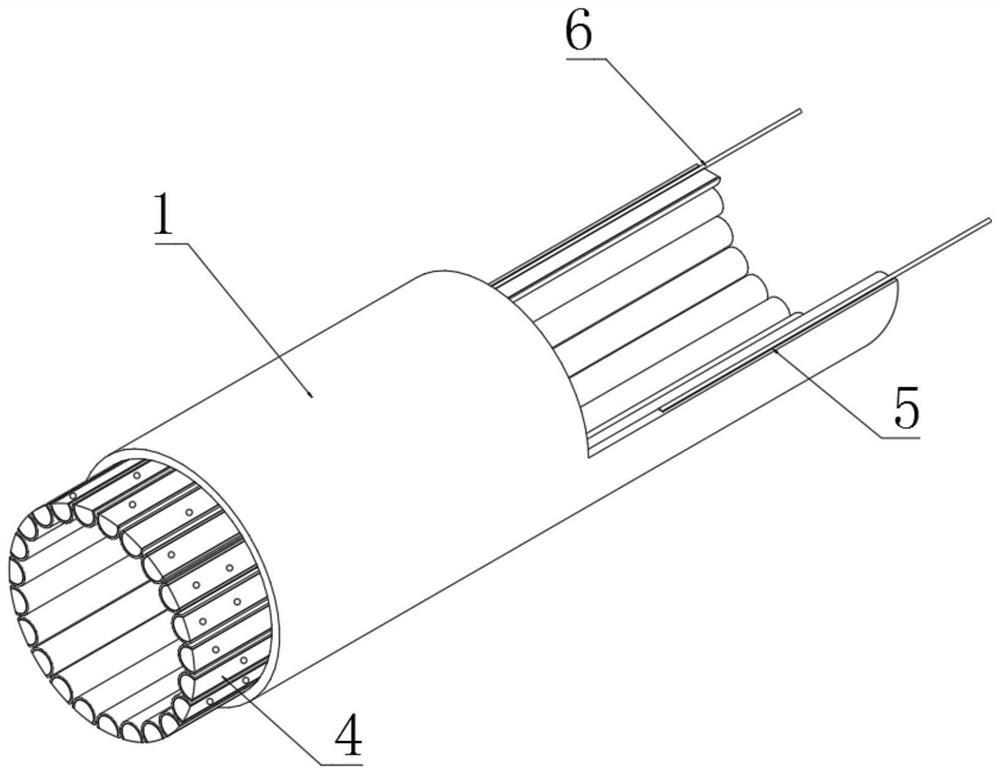

[0036] Such as Figure 1-4 As shown, the present invention provides a technical solution, a cable with high temperature resistance and long life, comprising an outer protective shell 1, the inner end surface of the outer protective shell 1 is uniformly bonded with a supporting soft rod 2, and the inner side of the supporting soft rod 2 is provided with a The arc-shaped fixing groove 3 is filled with polyimide filler 4, the supporting soft rod 2 has an arc-shaped structure, and the end faces of both sides of the supporting soft rod 2 are glued to the inner end face of the outer protective shell 1, The middle part of the polyimide filling material 4 is provided with a number of connection holes to facilitate the bending of the flexible rod 2. The two ends of the outer protective shell 1 are symmetrically provided with embedded grooves 5, and a pulling wire 6 is embedded in the embedded groove 5. Each end of the shell 1 is provided with two embedding grooves 5, the length of the ...

Embodiment 2

[0040] Such as Figure 5 As shown, the present invention provides a technical solution, a method for preparing a high-temperature-resistant and high-life cable, comprising the steps of:

[0041] S1, weighing and classifying the raw materials, and then mixing;

[0042] S2, after mixing, put it into an open mill for processing, then take it out and let it stand;

[0043] S3, adding a vulcanizing agent and a vulcanization accelerator, and vulcanizing it;

[0044] S4. After the processing is completed, it is left to be detected and then processed.

[0045] Further, the raw materials in S1 are the following parts by weight: 110 parts of insulating rubber powder, 2 parts of sulfur, 12 parts of transformer oil, 40 parts of talcum powder, 3 parts of wear-resistant carbon black, and 1 part of stearic acid.

[0046] Further, the temperature in S2 is 170 degrees, and the heat treatment time is 12 minutes;

[0047] The vulcanization time in the S3 is 27min, and the pressure is 12Mpa. ...

Embodiment 3

[0050] Such as Figure 5 As shown, the present invention provides a technical solution, a method for preparing a high-temperature-resistant and high-life cable, comprising the steps of:

[0051] S1, weighing and classifying the raw materials, and then mixing;

[0052] S2, after mixing, put it into an open mill for processing, then take it out and let it stand;

[0053] S3, adding a vulcanizing agent and a vulcanization accelerator, and vulcanizing it;

[0054] S4. After the processing is completed, it is left to be detected and then processed.

[0055] Further, the raw materials in S1 are the following parts by weight: 120 parts of insulating rubber powder, 1.5 parts of sulfur, 12 parts of transformer oil, 42 parts of talcum powder, 3 parts of wear-resistant carbon black, and 1 part of stearic acid.

[0056] Further, the temperature in S2 is 180 degrees, and the heat treatment time is 12 minutes;

[0057] The vulcanization time in the S3 is 30min, and the pressure is 12Mpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com