Rapid detection device and detection method for reliability of lithium battery current cut-off device

A current cut-off device and detection device technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of slow manual operation, lack of penetration, fire, etc., and achieve the effect of fast and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

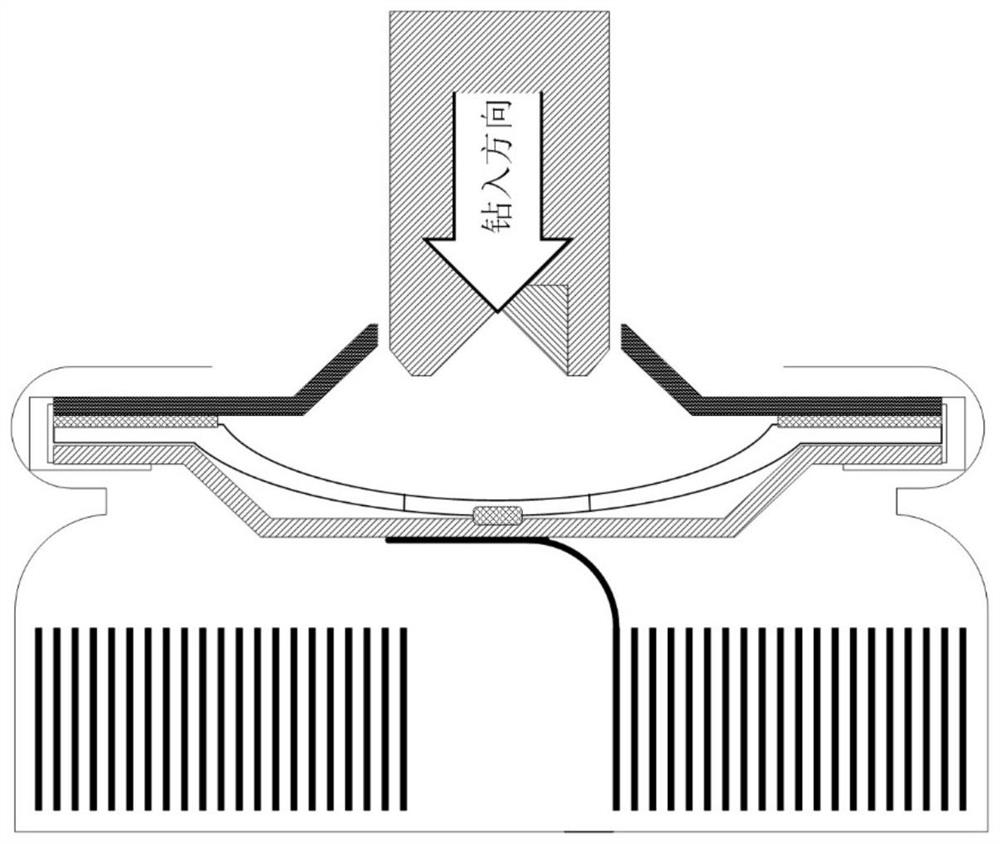

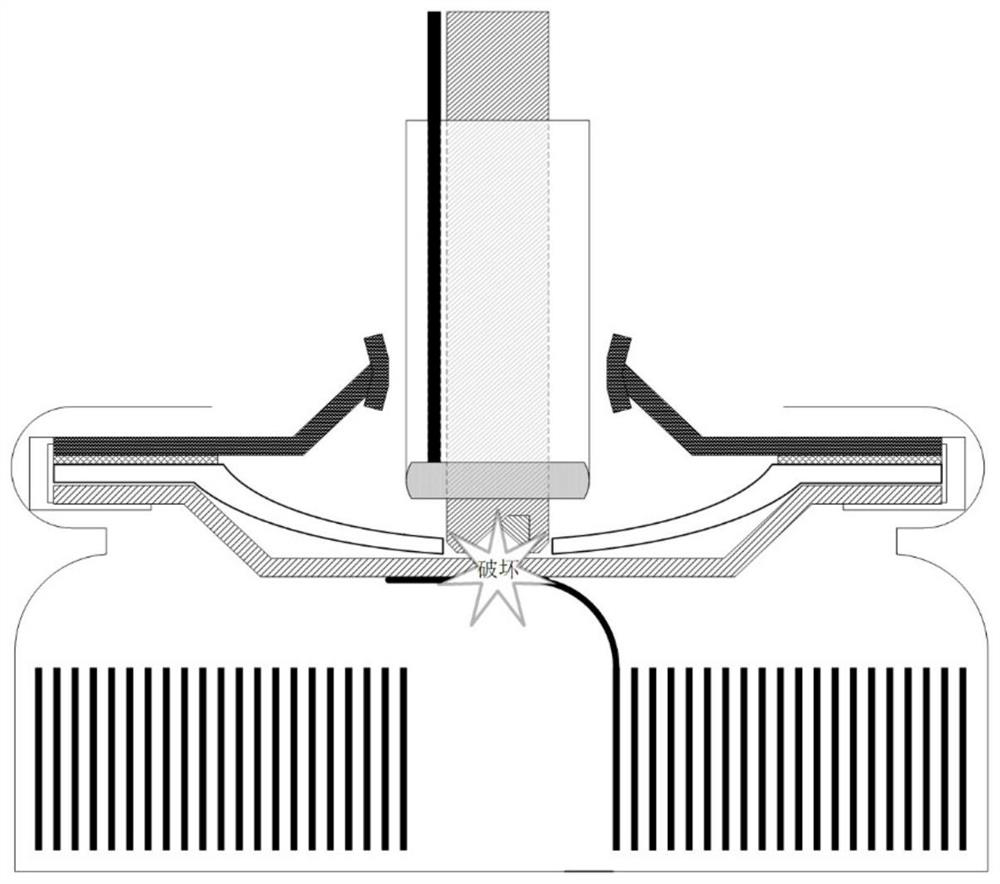

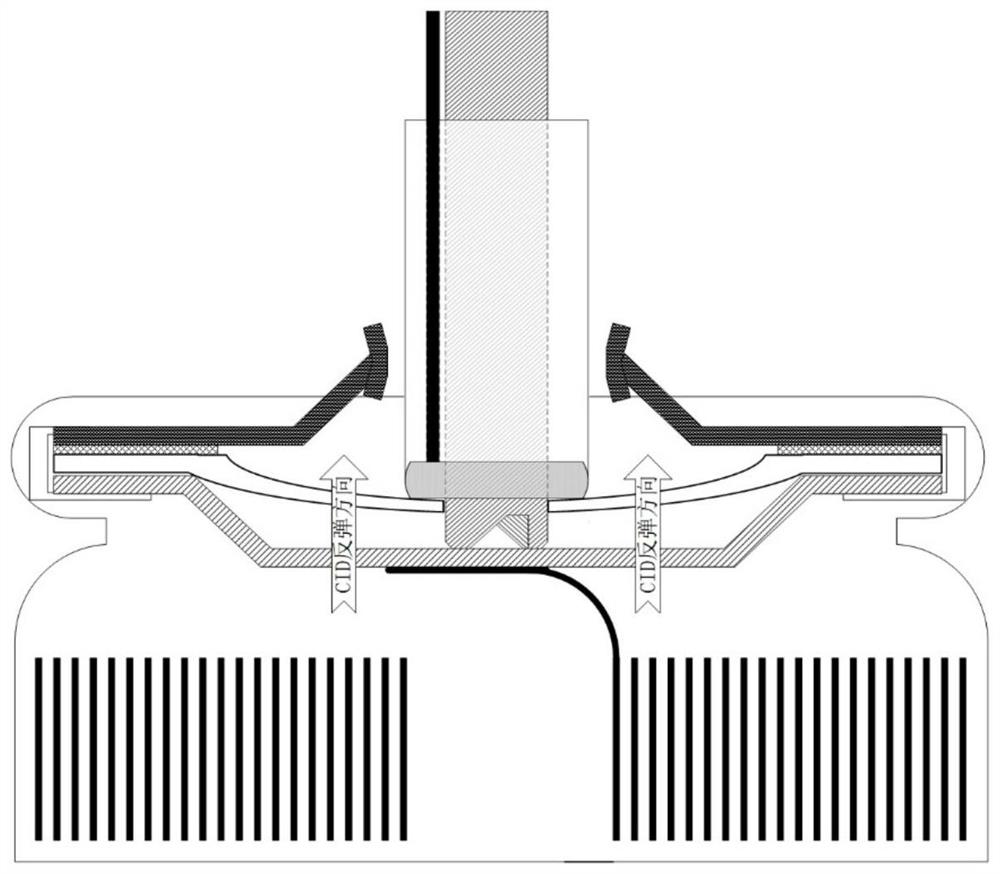

[0057] The rapid evaluation equipment for the reliability of the current interrupt device (CID) in the lithium battery in this embodiment, its structural schematic diagram is as follows Figure 4-8 As shown, it includes: a spindle box 1, a stepper motor 2, a programmable logic controller 3, a laser rangefinder 5, a test drill 6 or a standard drill 7 are installed on the spindle box 1, wherein the stepper motor 2 passes through a The leading screw 4 of the dust cover is connected with the column 8 and the base 11, and the workbench 10 is fixed on the column 8 with a fixed handle 9.

[0058] The overall device is a vertical drilling system structure, in which the headstock 1 provides power for the drilling parts of the drill bit, the stepper motor 2 and the lead screw 4 with a dust cover are responsible for providing power for the axial displacement of the headstock, and the laser measuring The spacer 5 is responsible for aligning the axial position of the spindle box and the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com