Self-powered downhole drilling tool vibration sensor based on friction nanometer generator

A technology of nano generators and vibration sensors, applied in friction generators, instruments, electrical devices, etc., can solve the problems of less reliability monitoring of drilling tools, and achieve improved working life and reliability, good sealing, and material less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

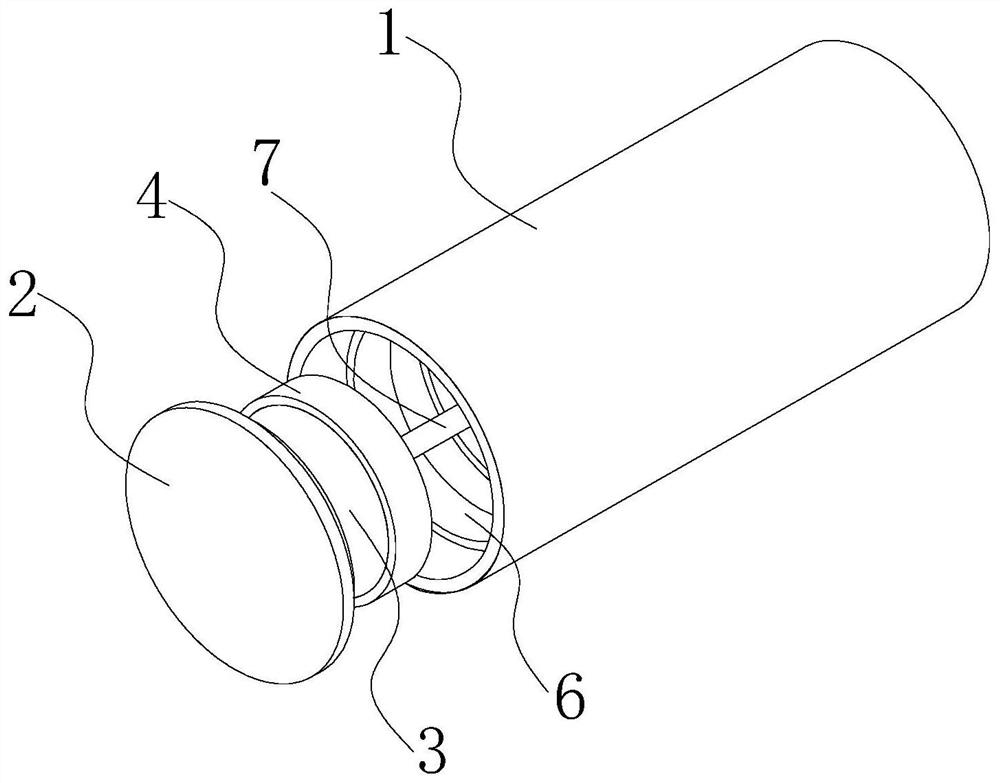

[0026] Please refer to figure 1 , 2 And 3, the embodiment of the present invention provides a kind of self-powered downhole drilling tool vibration sensor based on triboelectric nanogenerator, comprises casing, and the slide block 3 that accommodates in described casing, friction electrode 5, a plurality of sensor Electrode 6 and microcontroller.

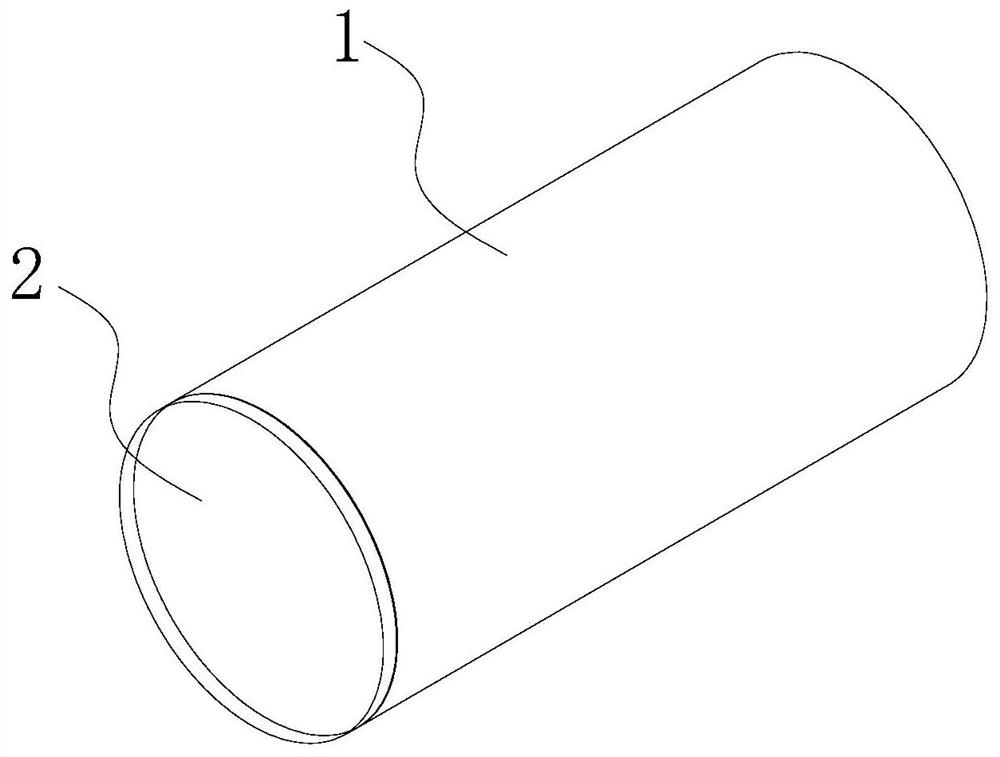

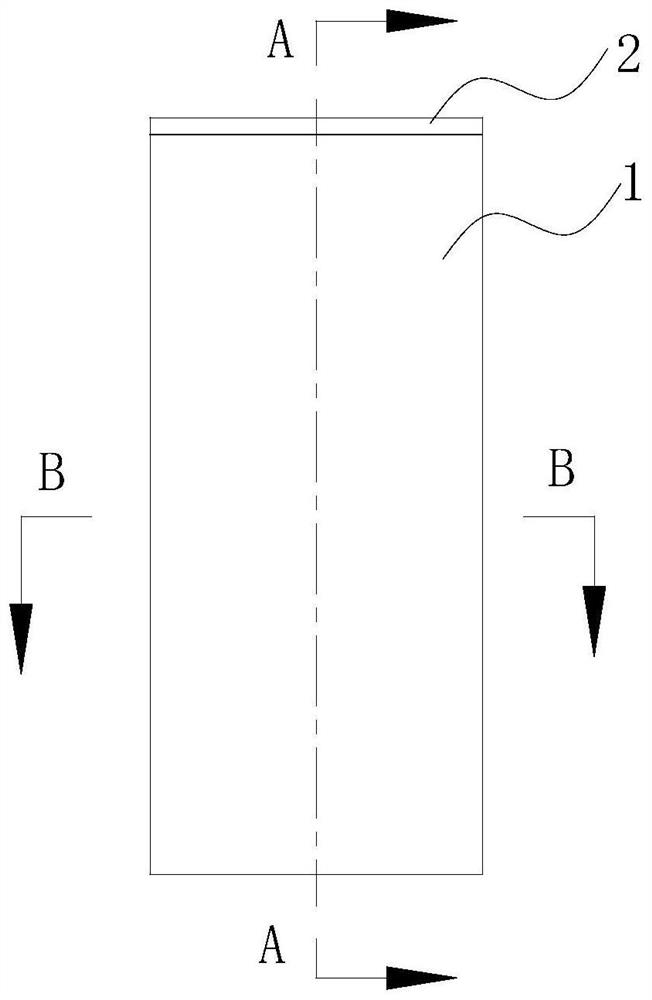

[0027] The casing is a closed insulating casing, which is connected with a downhole drilling tool and vibrates synchronously with the drilling tool. Here, the housing is a hollow cylindrical cylinder, specifically comprising a hollow cylindrical shell 1 with an open upper end and a top cover 2 , the top cover 2 covers the upper port of the shell 1 and seals the upper port of the shell 1 .

[0028] Please re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com