Multi-flame split type low-nitrogen combustor

A low-nitrogen burner, split-type technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of loss of boiler thermal efficiency, poor energy saving effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

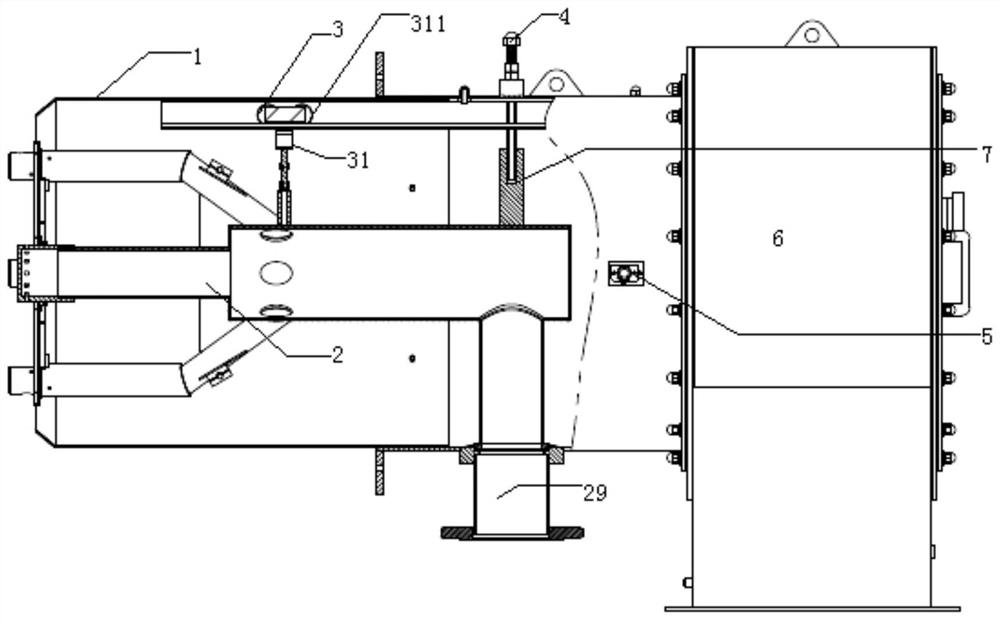

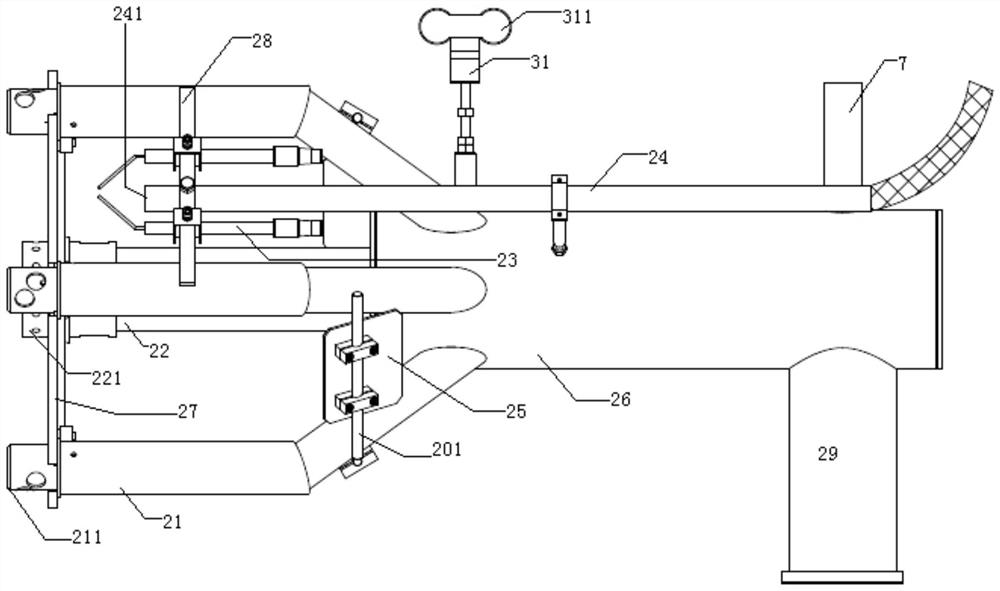

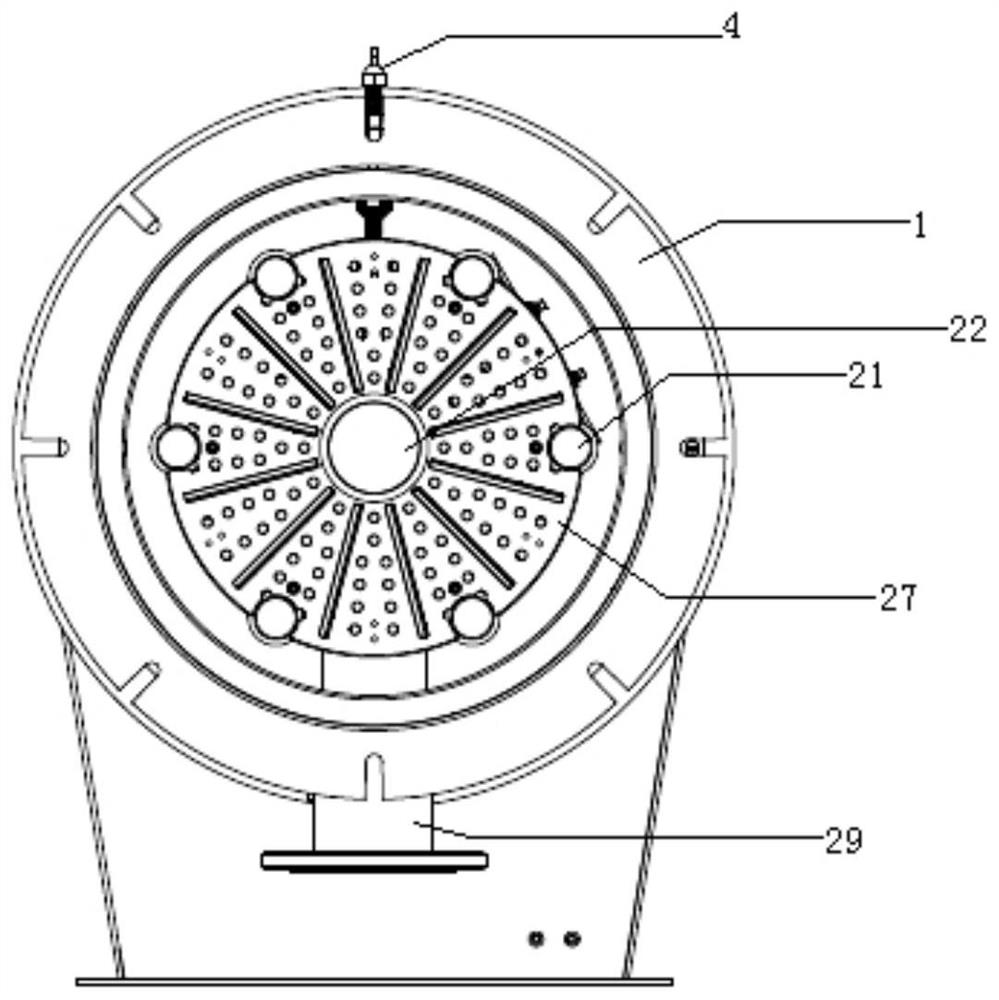

[0015] figure 1 , 2 , 3, and 4, a multi-flame split-type low-nitrogen burner, including a flame tube 1, a combustion head 2, a pulley guide rail 3, a positioning fastening screw 4, a flame monitor 5 and a bellows 6; The front end and the front end of the bellows 6 are connected together through flanges and screw nuts. The front end of the flame tube 1 is located inside the boiler furnace, and the rear end of the bellows 6 is connected to the external fan and air volume adjustment mechanism through pipes; Installed in the middle of the inner upper end of the flame tube 1, a pulley assembly 31 is installed inside the pulley guide rail 3, the pulley 311 of the pulley assembly 31 can move back and forth along the pulley guide rail 3, the lower end of the pulley assembly 31 is connected to the lower part of the rod and the gas distribution pipe of the combustion head 26 upper end outer middle parts are welded together, the upper end rear middle part of the pulley guide rail 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com