LED long-afterglow composite light-emitting lens and light-emitting device comprising LED long-afterglow composite light-emitting lens structure

A technology of long afterglow luminescence and long afterglow luminous powder, which is applied to optical elements for changing the spectral characteristics of emitted light, semiconductor devices of light-emitting elements, light sources, etc. Affecting luminous chromaticity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

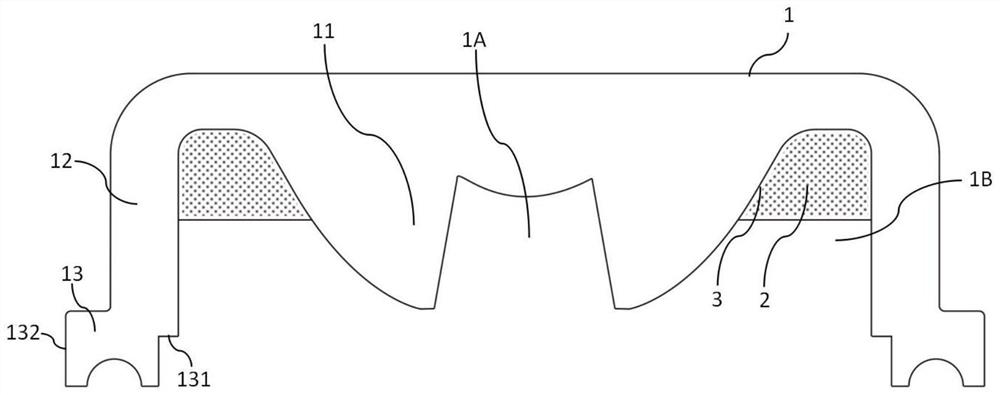

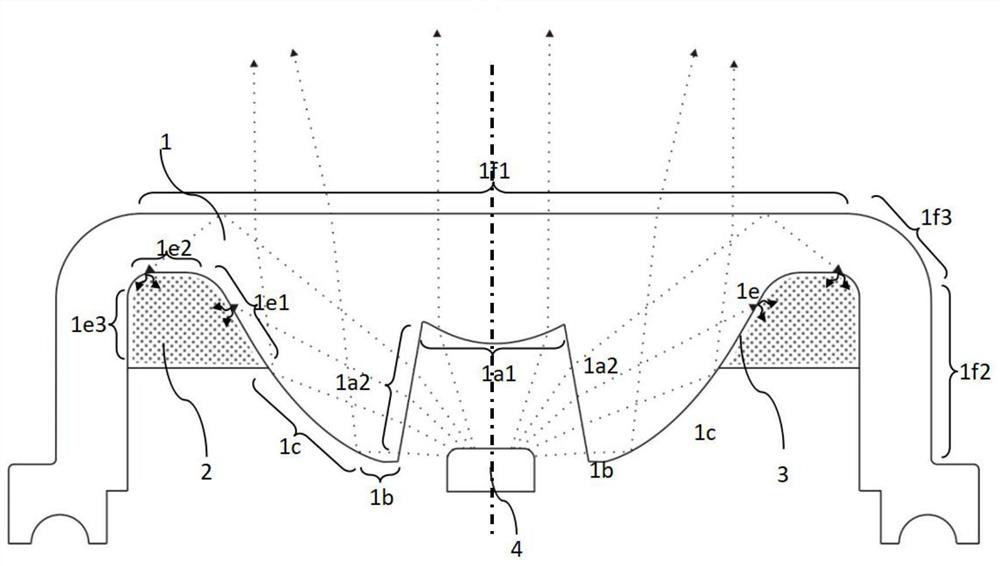

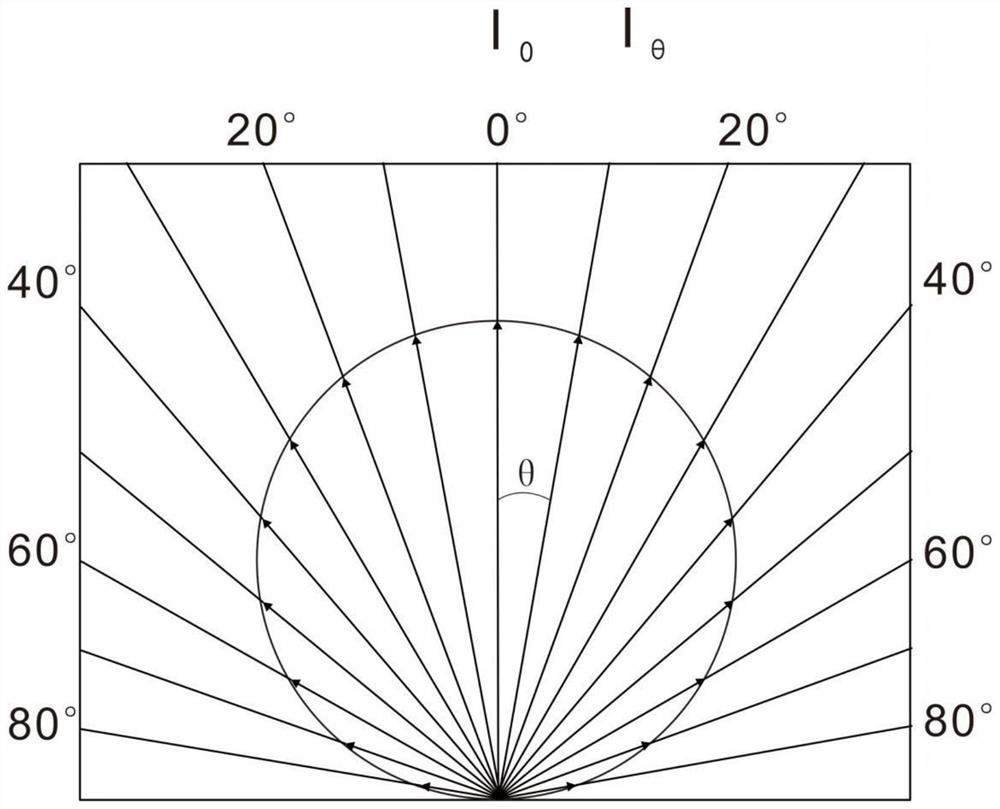

[0267] Embodiment 1 of the present invention provides an LED long-persistence composite light-emitting lens with a light-concentrating structure, wherein the LED long-persistence composite light-emitting lens includes a lens body structure (110), and the lens body structure (110) has a transparent surrounding The size of the main body of the light distribution optics gradually increases from bottom to top, and the center of the bottom of the main body of the light distribution optics is provided with a single hole-shaped center container that can enter the light of the light source and is symmetrical about the central axis. The cavity (110A), the inner wall of which is in the form of a paraboloid of revolution, the lighting part of the light distribution optical main part (1110) surrounds the central accommodating cavity (110A), and the side circumference of the LED long afterglow composite light-emitting lens is provided with the light distribution optical main part (1110). ) ...

Embodiment 2

[0303] Embodiment 2 of the present invention provides a LED long-lasting composite light-emitting lens with a diverging structure, such as Figure 77 As shown, it includes the lens body structure (210), the edge of the lens body structure (210) has an upturned transparent surround, the light distribution optics main part (2110) is a raised arch, and the light distribution optics main part (2110) A central accommodation chamber (210A) is provided at the center of the bottom of the center housing for light from the light source to enter. The light incident surface (210a1) of the top wall of the central accommodation chamber (210A) is a concave free-form surface, and the light incident surface (210a1) of the top wall The curvature is larger than the curvature of the corresponding part of the light-emitting surface (210f), and an annular groove is provided between the outer wall of the lighting part and the bulge of the light-emitting part. The liquid mixed slurry of the medium is...

Embodiment 3

[0312] Embodiment 3 of the present invention provides an LED long afterglow composite light-emitting lens with a TIR total reflection structure combined with a prism orientation angle (deflected by a certain angle along the axial direction) exit structure, such as Figure 94 As shown, it includes the lens body structure (310), the edge of the lens body structure (310) has a transparent surround (3120), and its light distribution optical main part (3110) gradually increases in size from bottom to top, and the light distribution optical main part The bottom of (3110) is provided with the central accommodating chamber (310A) that can enter the light of the light source, and the outer wall of the lighting part surrounding the central accommodating chamber (310A) is provided with a TIR total reflection surface (310c), and the outer side of the lighting part A ring-shaped groove is provided between the wall and the inner side wall of the transparent surround, and the long-lasting lum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com