Speed reducer assembly

A technology of reducers and components, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of limiting the performance of mechanical arms, low integration, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

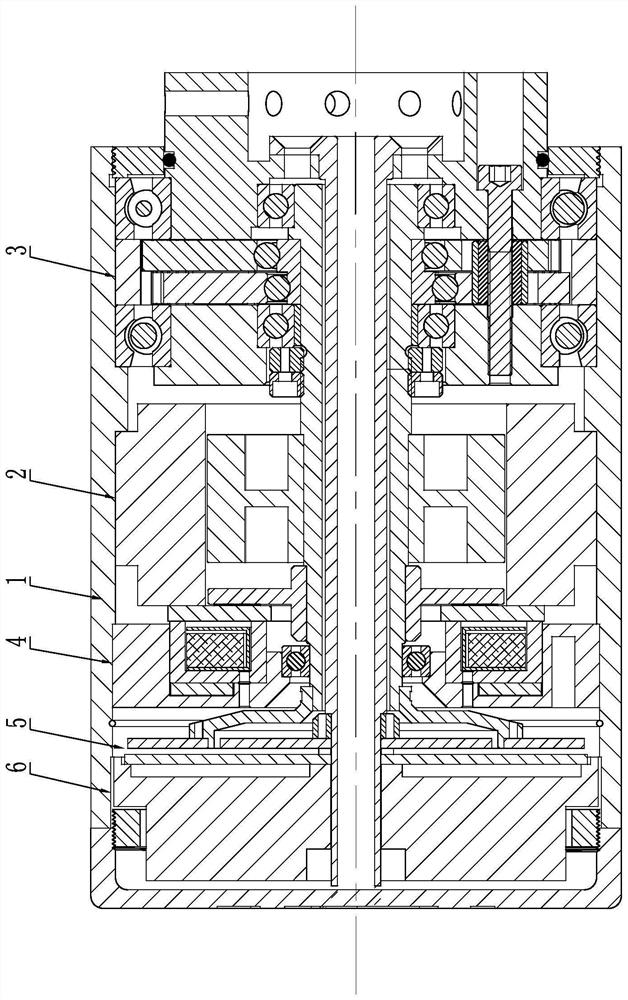

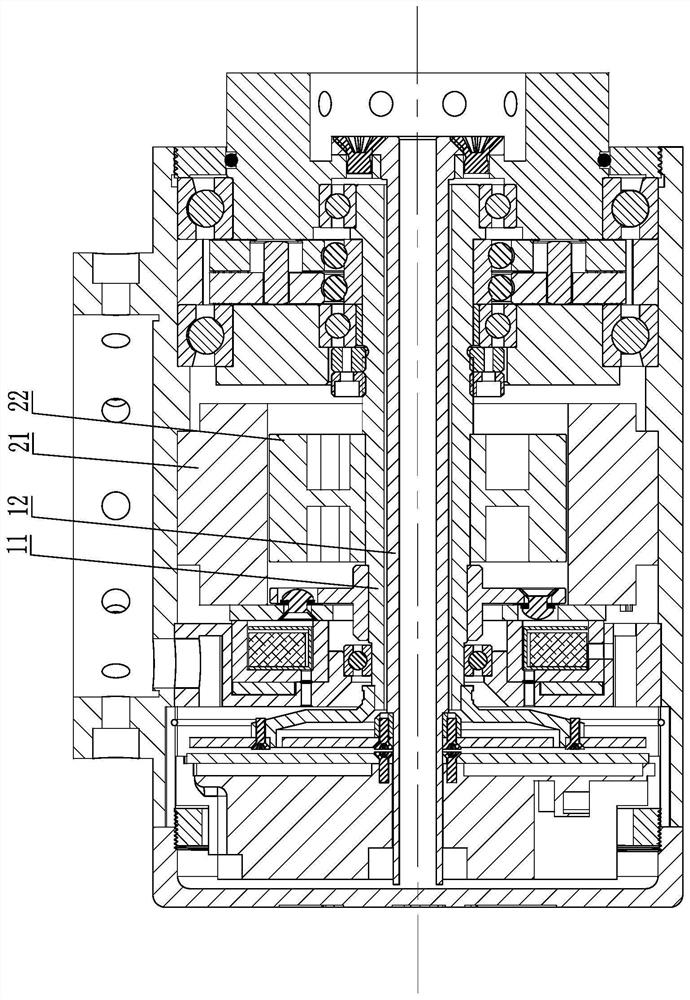

[0030] Such as figure 1 and figure 2 As shown, the joint of the manipulator includes the joint housing 1. The joint housing 1 is used as the installation carrier of the manipulator joint. It is formed by fastening a main housing and a side end cover. The main housing and the side end cover The covers can be threaded or screwed. A motor assembly 2, a reducer assembly 3, a brake assembly 4, an encoder assembly 5, and a drive assembly 6 are installed in the joint housing 1, and each assembly is arranged inside the joint housing 1 to form an integrated joint structure; The joint housing 1 is provided with a housing mounting seat for connecting the joint of the mechanical arm to the mechanical arm, and the housing mounting seat is a mounting flange; the surface of the joint housing 1 is provided with a wire passing through The hole is arranged inside the installation flange, which can facilitate the connection with other mechanical arms and avoid the leakage of the wire hole.

...

Embodiment 2

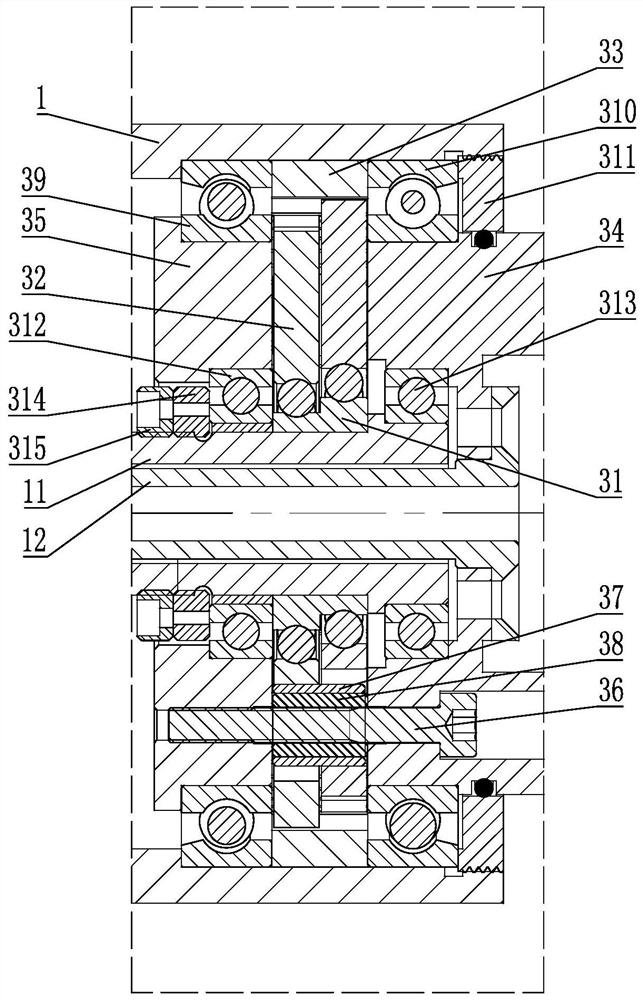

[0049] The difference between the second embodiment and other embodiments is that the structure of the bearing eccentric sleeve is different, and other structures are the same.

[0050] The bearing eccentric sleeve in Embodiment 1 has an integral structure, see image 3 , that is, the outer circumference of a bearing eccentric sleeve is equipped with two transmission gears through two bearing balls, and in this embodiment, the bearing eccentric sleeve includes N eccentric bearings sequentially installed on the power output and output shaft, N≥ 2. The phase angle between adjacent eccentric bearings is 360° / N, and an eccentric installation position is formed on the outer circumference of each eccentric bearing, see Figure 4 The intermediate reducer assembly is provided with three eccentric bearings, the phase angle between the three eccentric bearings is 120°, and each eccentric bearing is equipped with a transmission gear, that is, the number of transmission gears corresponds ...

Embodiment 3

[0052] The difference between the third embodiment and other embodiments is that the structure of the pin sleeve 37 is different, and the other structures are the same.

[0053] The pin bushing in Embodiment 1 has an integrally formed structure, see image 3 , because the phase angles of the two transmission gears are different, that is, the direction of the force acting on the pin sleeve when the two transmission gears move is different, so that there is a tangential torque in the pin sleeve, and this torque causes the transmission gear and the pin shaft to The friction between the sleeves is relatively large, which will reduce the efficiency of torque transmission. In order to solve this problem, the pin sleeve is set as a segmented structure, see Figure 4 , in this embodiment, the pin sleeve includes at least two sub-sleeves that are sequentially connected, the number of the sub-sleeves corresponds to the number of the transmission gears, and the outer circumference of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com