Circular prestressed support system for subway connection channel construction and assembling method

A communication channel and prestressing technology, applied in tunnels, shaft equipment, earthwork drilling and mining, etc., can solve the problems of stratum stress balance damage, unsatisfactory construction effect, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

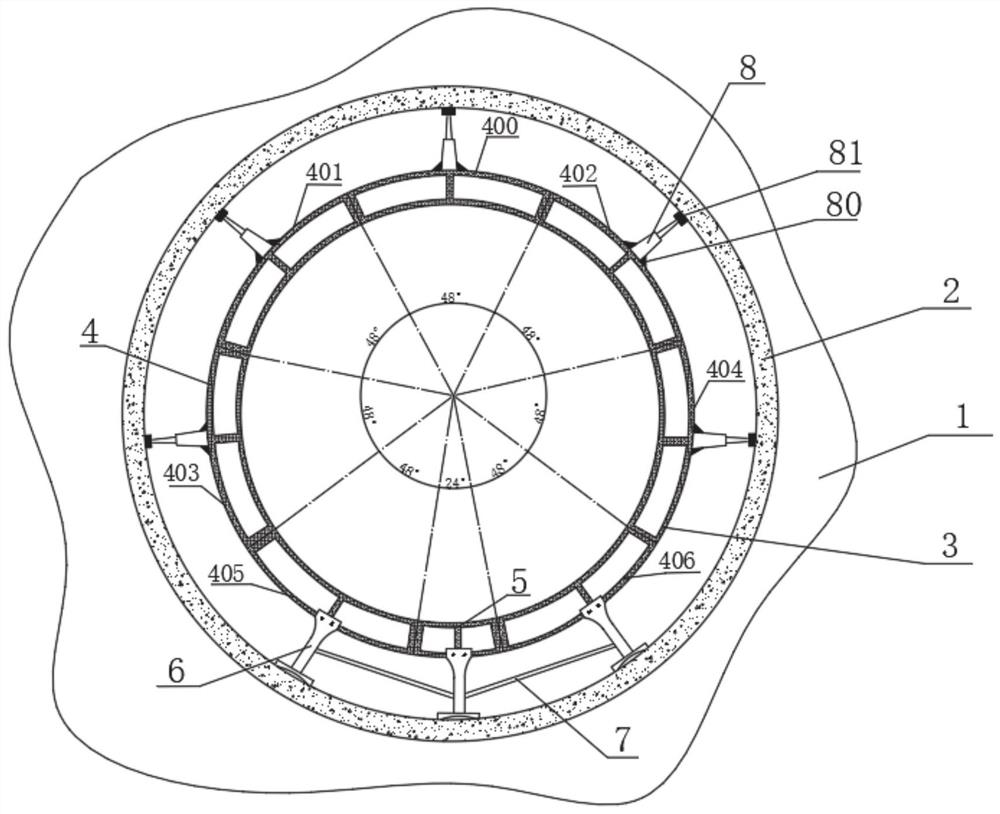

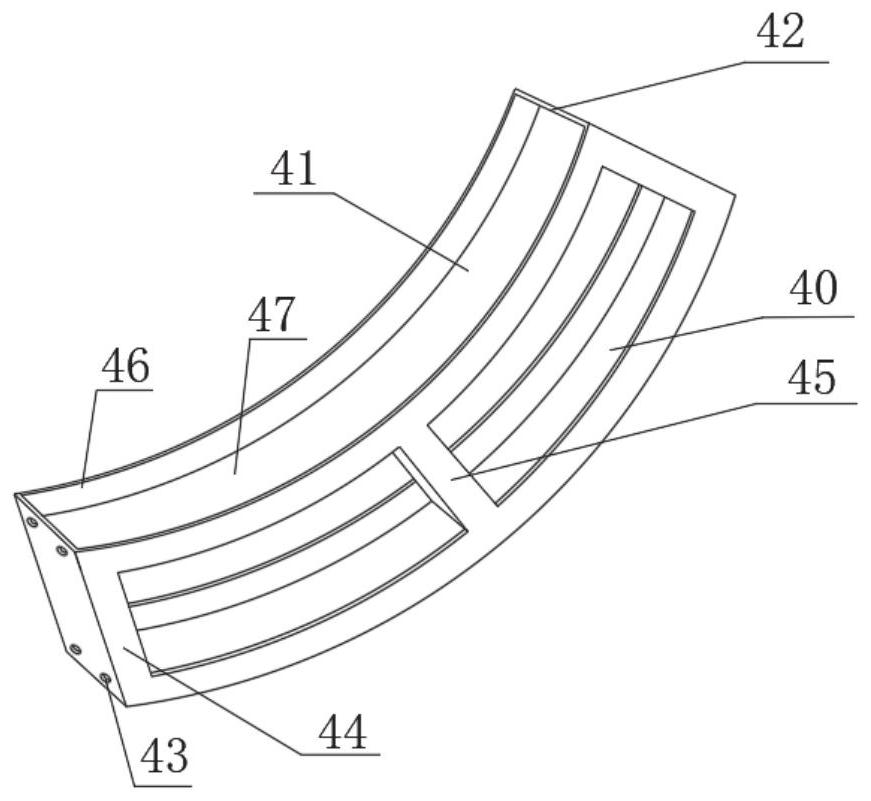

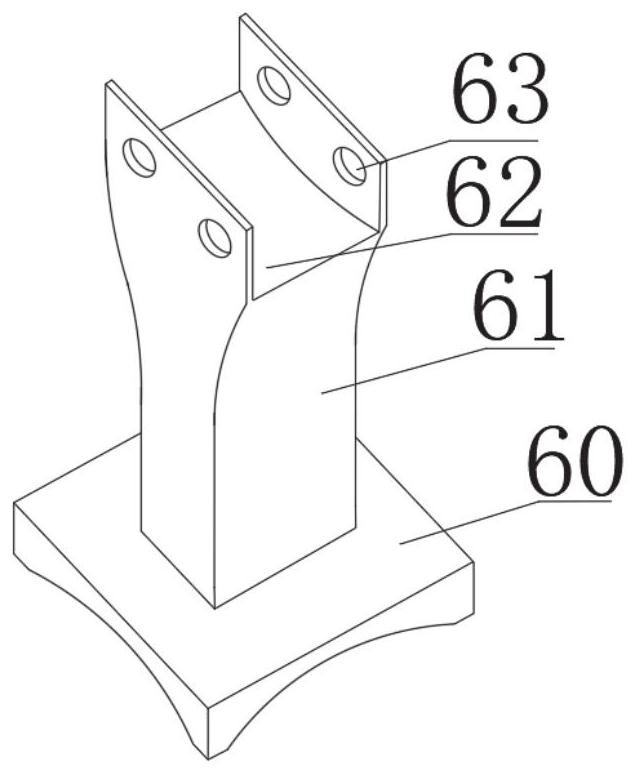

[0031] In a typical implementation of the present invention, this embodiment discloses a circular prestressed support system for subway communication passage construction, which includes a plurality of prestressed supports, and adjacent supports are connected by connecting pieces. The prestressed support includes a first arc-shaped prefabricated part 4, a second arc-shaped prefabricated part 5, a rigid pier 6 and a jacking mechanism, the first arc-shaped prefabricated part 4 includes a plurality, and the second arc-shaped prefabricated part 5 includes one, A plurality of first arc-shaped prefabricated parts and a second arc-shaped prefabricated part are connected end to end to form an annular support 3, the first arc-shaped prefabricated part 4 and the second arc-shaped prefabricated part 5 form the main structure supporting the tunnel, and the two arc-shaped prefabricated parts The parts can fully share the stress from the subway tunnel and improve the stability of the support...

Embodiment 2

[0071] In a typical implementation of the present invention, this embodiment discloses an assembly method of a circular prestressed support system for the construction of a subway communication channel, which is used for assembling the circular prestressed support system for the construction of a subway communication channel as described in Example 1. A prestressed support system comprising the following steps:

[0072] Set up multiple rows of rigid buttresses;

[0073] A second curved prefabricated part is arranged on each row of rigid piers, and the first curved prefabricated part is connected on both sides of the second curved prefabricated part;

[0074] The connecting piece is connected between the rigid piers in the same row;

[0075] Simultaneously connecting a pair of first curved prefabricated parts at the same height until the annular support is formed;

[0076] At the same time, a pair of screw jacks at the same height are connected to the corresponding first arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com