Anchorage foundation formed by three groups of annular waste tires and steel piles and construction method of anchorage foundation

A waste tire and ring-shaped technology, which is applied in the field of mooring systems, can solve the problems of anchoring and damage, and achieve the effect of heavy weight, simple construction and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

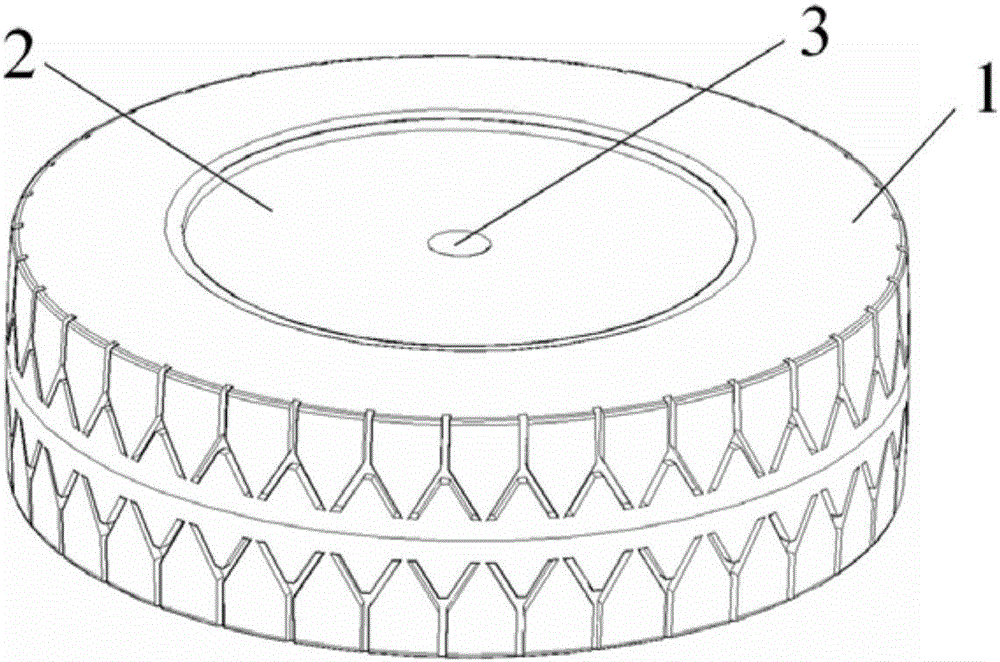

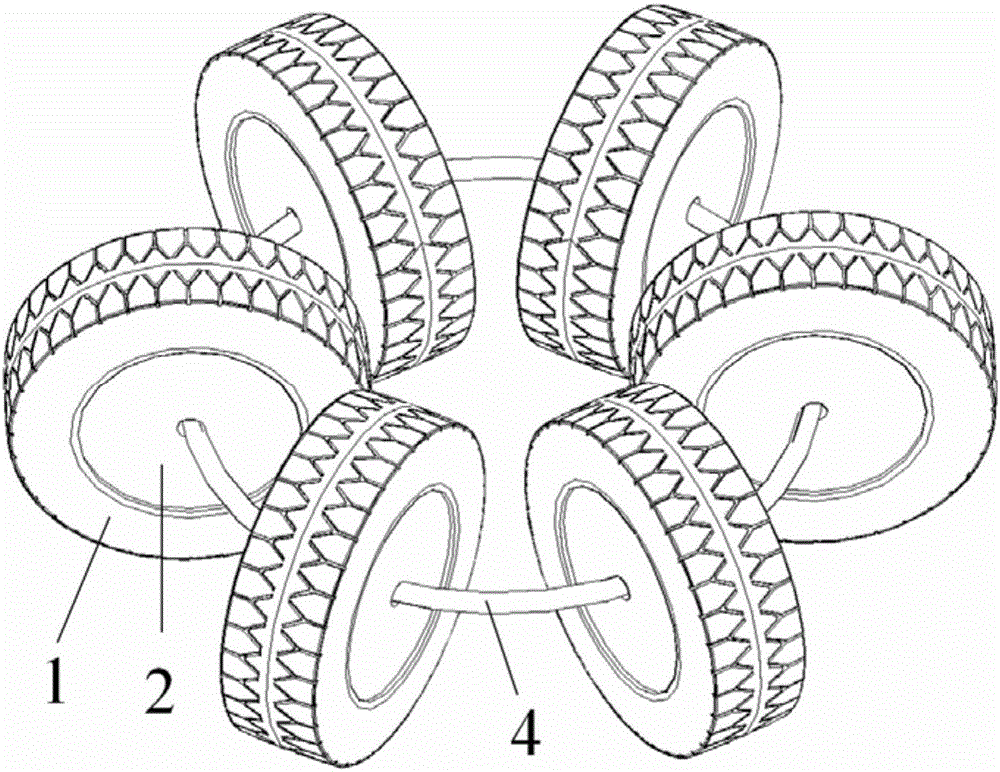

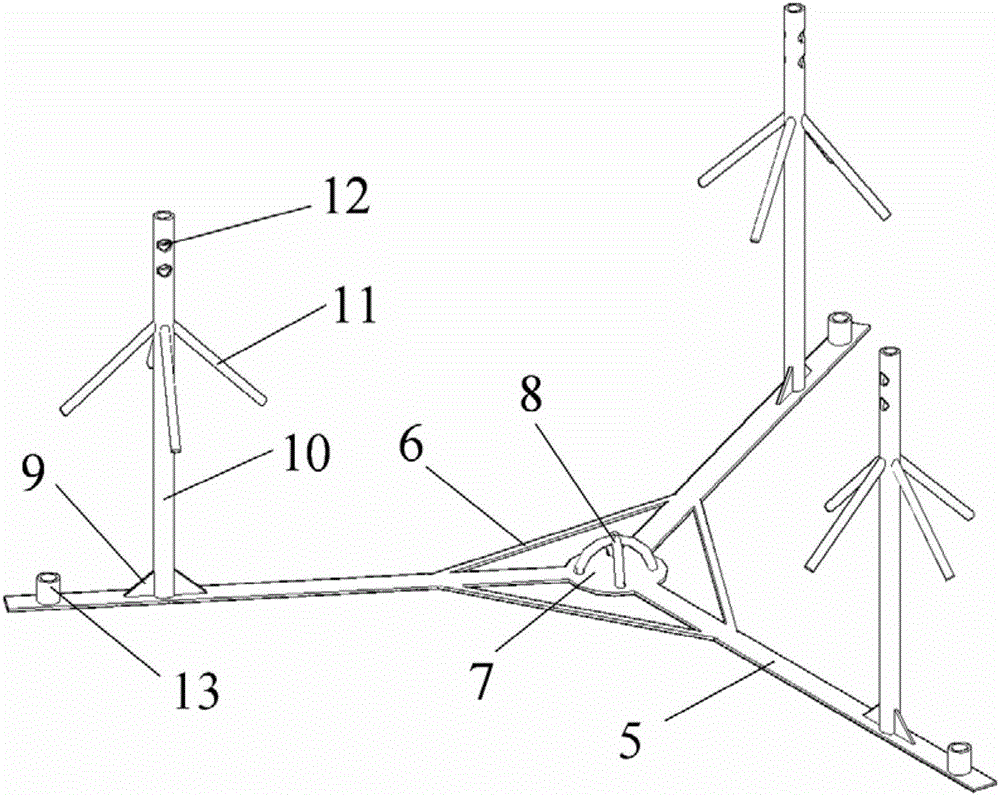

[0035] See attached picture:

[0036] The mooring foundation formed by three groups of ring-shaped waste tires and steel piles includes ring-shaped waste tire counterweights, steel piles and connecting brackets. The waste tire counterweights are formed by pouring reinforced concrete 2 inside the waste tires 1 and are formed by steel cables. 4 Bind a number of waste tire counterweights together to form a ring; the main body of the connecting bracket is three connecting plates 5 that form an angle of 120° with each other, and the three connecting plates 5 are connected by a circular plate 7, and the circular plate 7 is A suspension ring 8 is provided, a sleeve 10 is provided near the other end of the connecting plate 5, and a sleeve 13 is provided at the end, and an anti-off rod 11 and a construction hole 12 are arranged on the middle and upper part of the sleeve 10; during work, the three steel piles 14 Insert three sleeves 13 and fix them with connectors (bolts) 19, fasten the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com