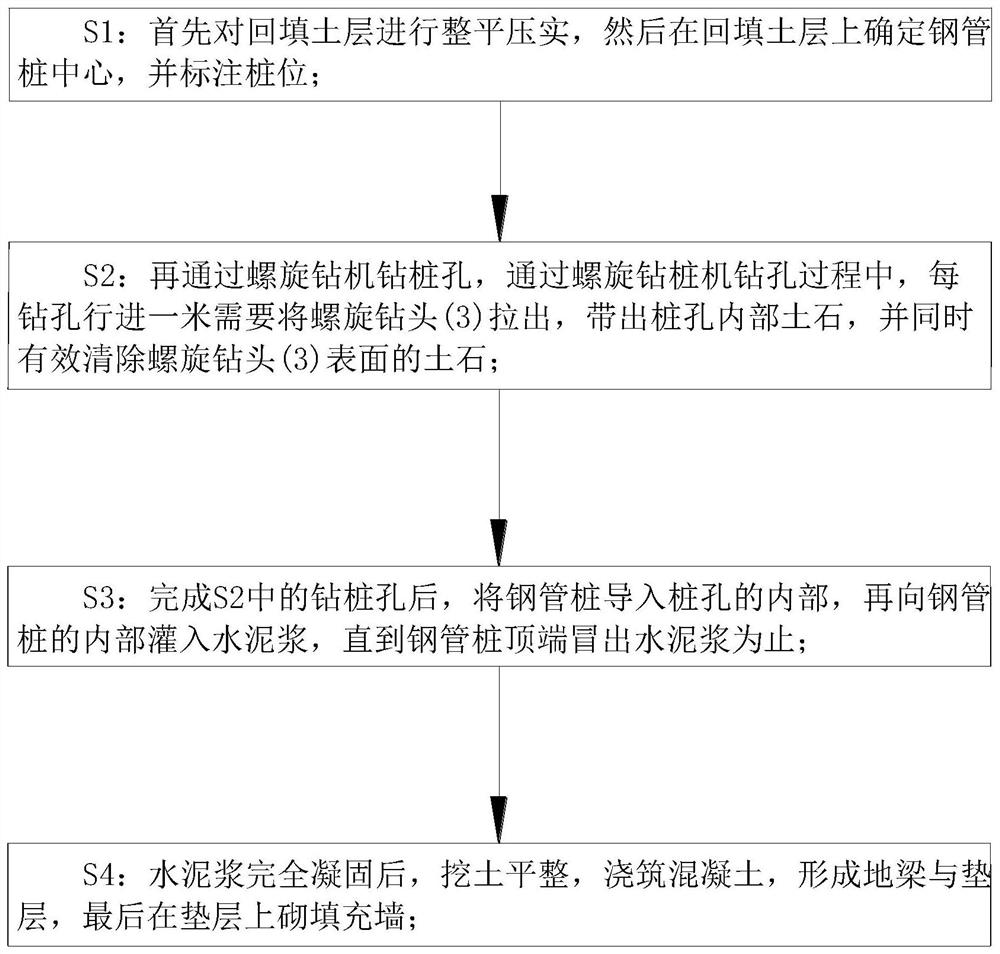

A Construction Method for Filling Wall Foundation with Deep Backfilling Soil

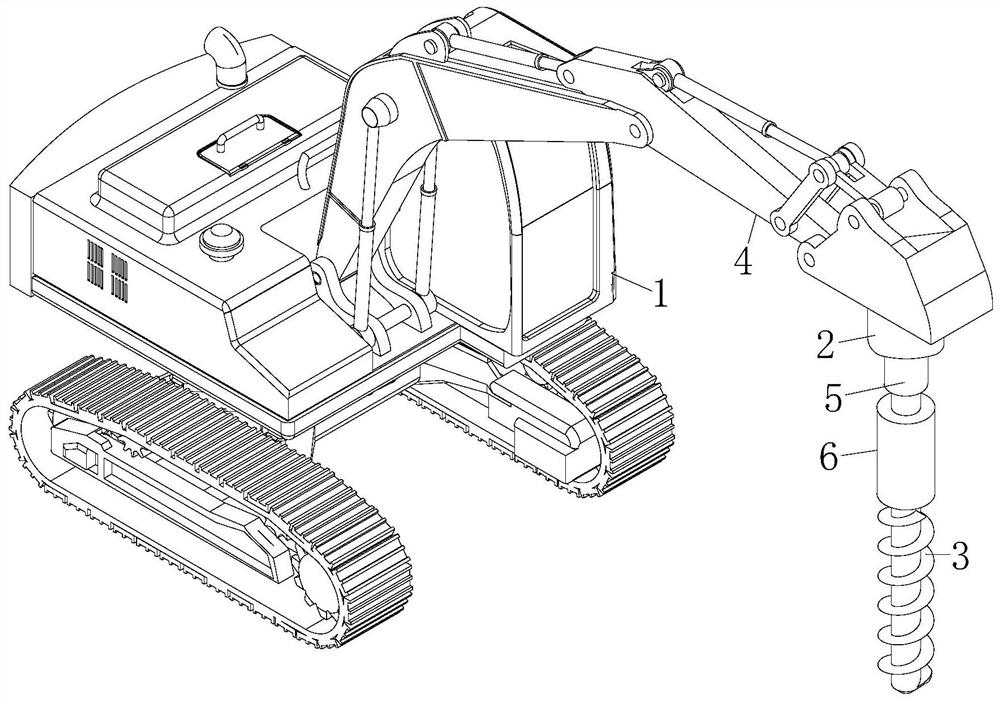

A technology for foundation construction and backfilling, which is used in foundation structure engineering, sheet pile walls, earthwork drilling, etc. It can solve the problems of affecting the introduction of steel pipe piles, cannot be effectively exported, and residual soil and stone, so as to improve the ability to carry soil and stone. , Reduce the sidewall soil and stone falling, reduce the effect of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

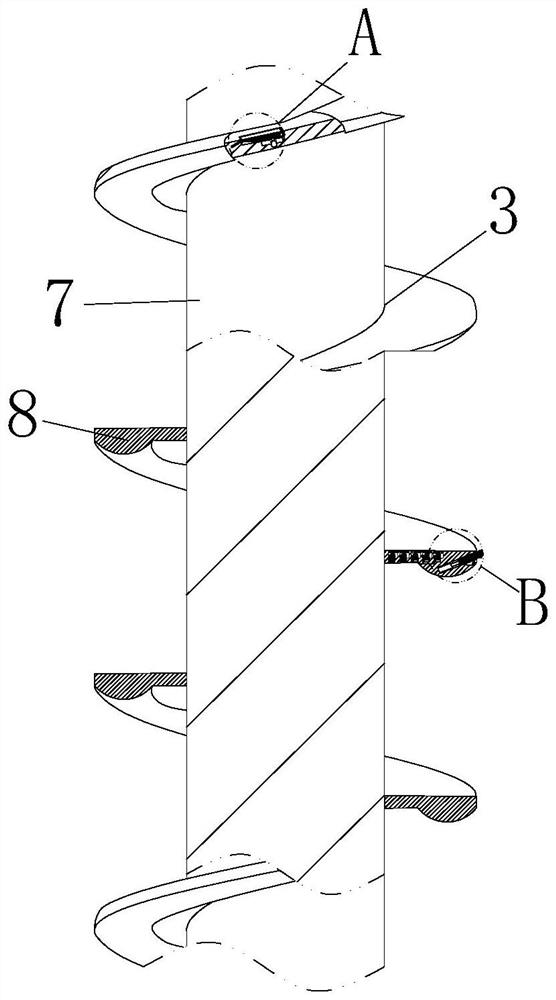

[0038] As an embodiment of the present invention, the sides of the rotating grooves are all provided with chute; the inside of the chute is slidably connected with a slider 13; between the slider 13 and the groove bottom of the corresponding chute The first spring is fixedly connected; the corrugated elastic sheet 14 is fixedly connected between the corresponding baffle plates 9 of the slider 13; during work, by setting the slider 13, when the baffle plate 9 rotates and leads to the corresponding rotation groove, the baffle plate 9 It will drive the corrugated elastic sheet 14 to stretch, and during the stretching process of the corrugated elastic sheet 14, the corrugated elastic sheet 14 will pull the slider 13, so that the slider 13 slides inside the corresponding chute, and stretches the first spring, and the derived corrugated The elastic sheet 14 can seal the notch of the rotating groove, so as to prevent the earth and stone or water on the surface of the spiral blade 8 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com