Concrete building device suitable for linear steep tank flood overflow tank

A technology for concrete construction and flooding, which is applied in construction, measuring devices, lubrication indicating devices, etc., and can solve problems such as being easily mixed with a large amount of sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

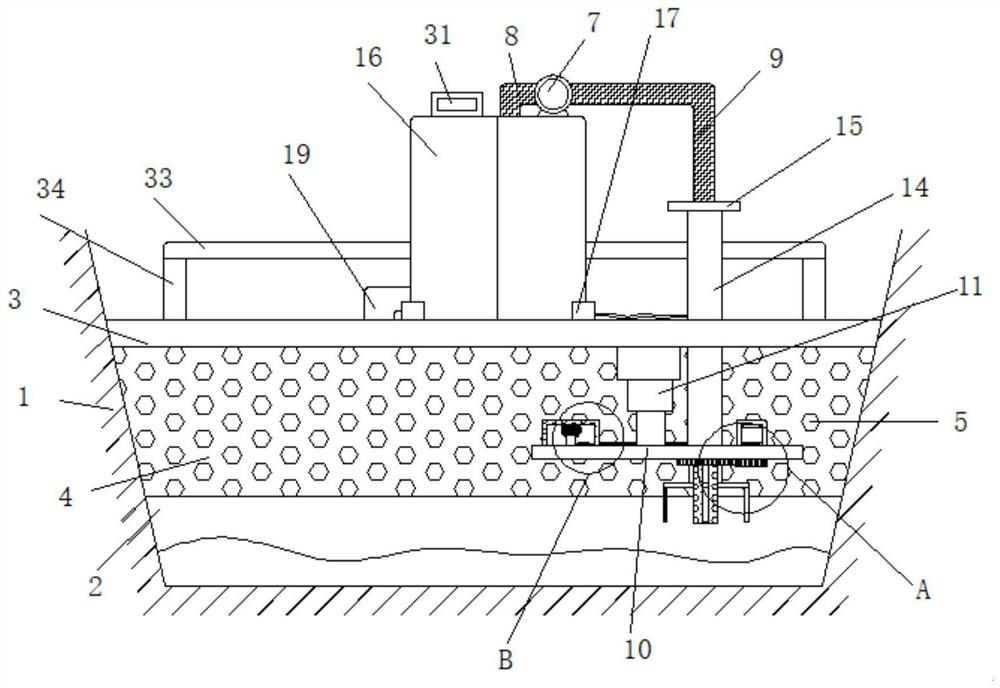

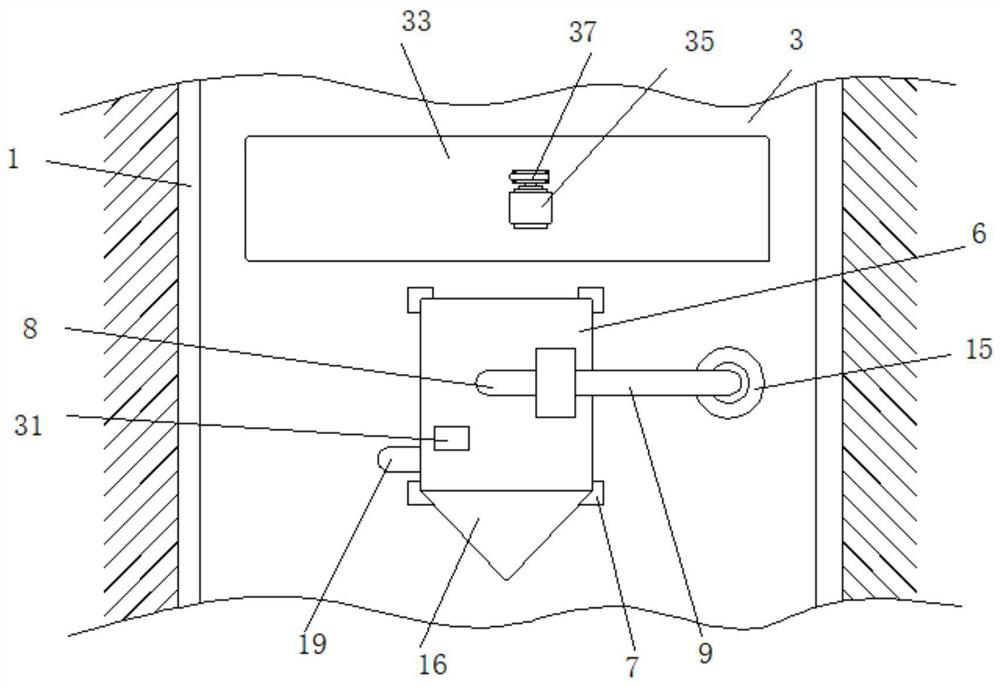

[0033] Embodiment one, such as Figure 1-9 As shown, a concrete construction device suitable for a straight-line steep trough spillway includes a spillway 1 whose cross-section is an inverted isosceles trapezoid. The bottom of the spillway 1 is provided with a sand storage tank 2. A fixed plate 3 is arranged horizontally above the tank 2, and both ends of the fixed plate 3 are respectively fixedly connected with the side wall of the overflow tank 1. The bottom surface of the fixed plate 3 is fixedly connected with an intercepting plate 4, and a plurality of filter holes 5 are uniformly arranged on the intercepting plate 4. The intercepting plate 4 is arranged vertically, the two ends of the intercepting plate 4 are in contact with the side wall of the overflow tank 1, the intercepting plate 4 is in contact with the side wall of the sand storage tank 2, the upper surface of the fixed plate 3 is equipped with a collection box 6, and the upper surface of the collection box 6 The ...

Embodiment 2

[0034]Embodiment two, such as Figure 1-3 , 5, a protective tube 14 is vertically arranged on the outer side of the telescopic tube 9, the protective tube 14 surrounds the telescopic tube 9, the protective tube 14 is fixedly connected with the upper surface of the connecting plate 10, and the protective tube 14 runs through the fixed plate 3 and connects with it Slidingly connected, the top of the protective tube 14 is fixedly connected with the limit ring 15, and the protective tube 14 protects the telescopic tube 9 to prevent the flowing animals in the river from damaging the telescopic tube 9.

Embodiment 3

[0035] Embodiment three, such as Figure 1-3 As shown, the side of the collection box 6 facing the upstream of the overflow tank 1 is fixedly connected with a drag reducing member 16. The drag reducing member 16 is in the shape of a triangular prism, and the collecting box 6 and the four corners are all provided with L-shaped fixing members 17. A plurality of fixing parts 17 are fixedly connected with the upper surface of the fixing plate 3, and a plurality of fixing parts 17 are in contact with the collection box 6, wherein two of the fixing parts 17 are in contact with the drag reducing parts 16, and the fixing parts 17 make the collection box 6 Installation and disassembly are simpler and more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com