Intermittent cloth storage and centralized cloth discharging device for cloth dyeing and cloth circulation dyeing machine

A dyeing machine and cloth technology, which is applied to liquid/gas/vapor processing transmission, processing textile material carrier, liquid/gas/vapor jet propelling fabric, etc., can solve the problem of limited fluid action strength and range, and cloth action efficiency needs to be improved And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

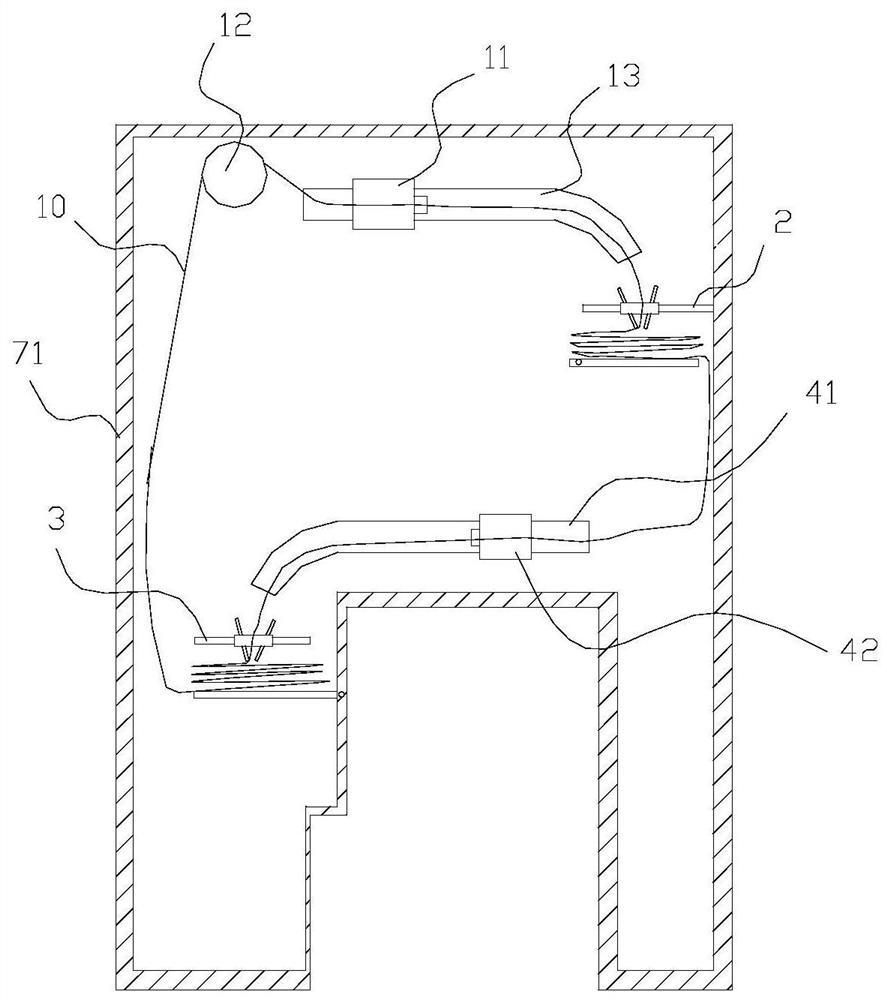

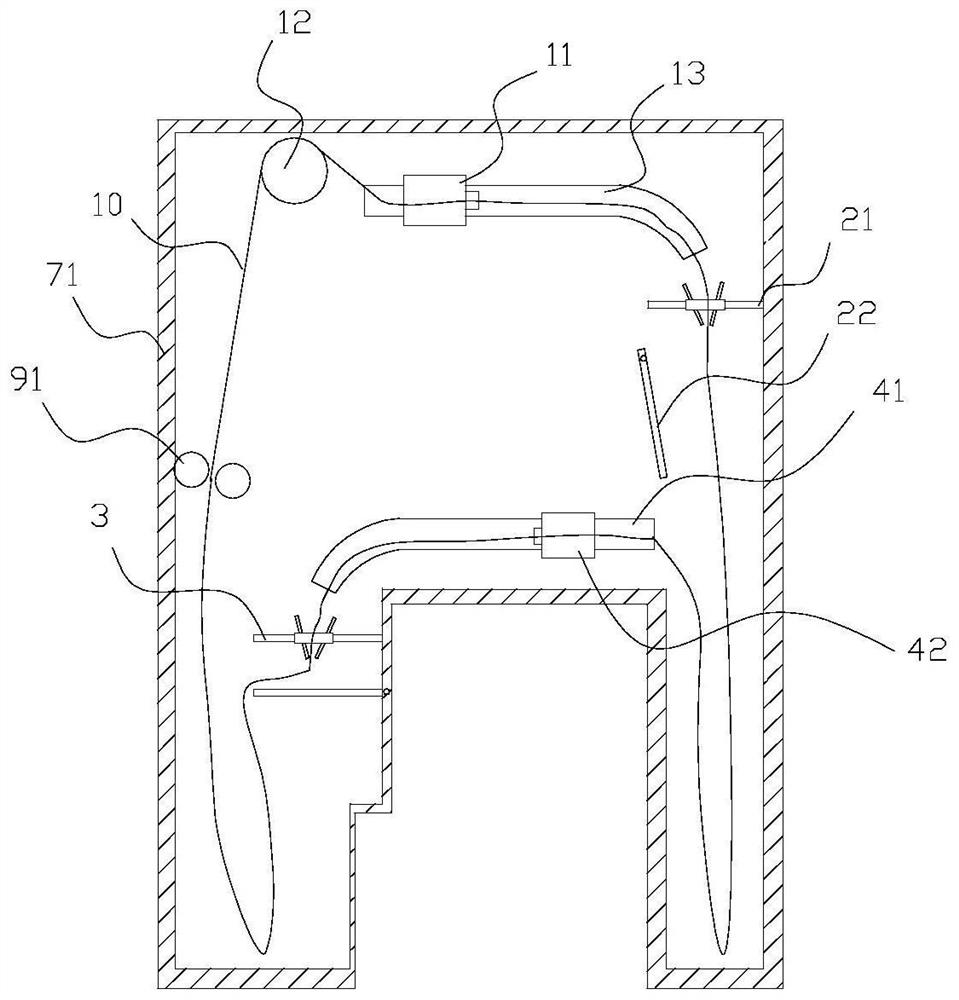

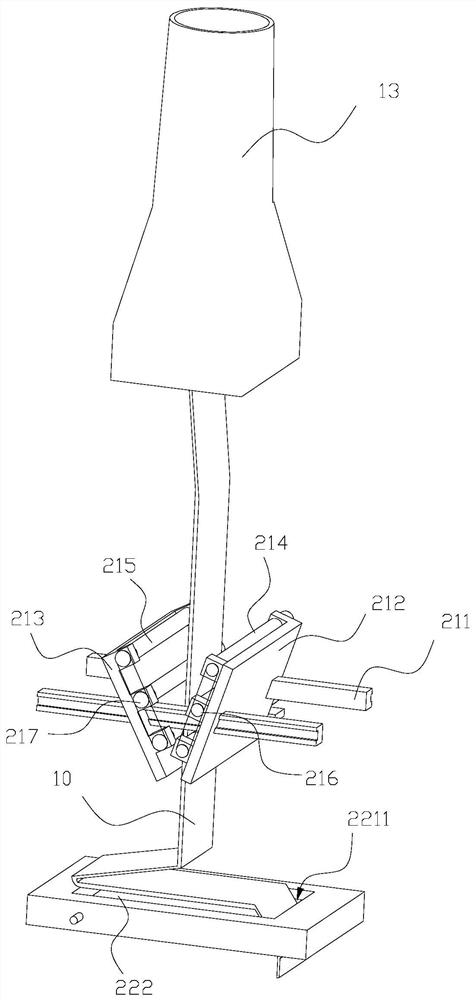

[0047] like figure 1 , 2 As shown, the present embodiment discloses a cloth circulation dyeing machine, which includes a primary nozzle 11, a cloth lifting device 12, and a primary cloth guiding pipe 13. The liquid energy drives the cloth 10 to move toward the outlet of the primary cloth guide pipe 13 .

[0048] It also includes a first intermittent cloth storage centralized cloth lowering device 2 , a second intermittent cloth storage concentrated lower cloth device 3 , a secondary cloth guide pipe 41 , and a secondary nozzle 42 . The first intermittent cloth storage centralized cloth lowering device 2 is used for reciprocating and stacking the cloth 10 falling from the outlet of the primary cloth guiding pipe 13 from bottom to top and intermittently collecting and lowering the cloth 10 stacked therein. The cloth 10 passing through the first intermittent cloth storage centralized cloth lowering device 2 can enter into the secondary cloth guiding pipe 41, and the dye liquor ...

Embodiment 2

[0085] like Figure 9-12 As shown, the difference between this embodiment and the above-mentioned embodiments is that this embodiment discloses a drive device with another structure, and the drive device includes a connecting plate 21481, a drive motor, a lower cloth rotating shaft 21461, a rotating rod 21482, and a driven slider 21483 , Drive rod 21484, drive slider 21485, intermittent gear transmission assembly.

[0086] The connecting plate 21481 is connected between the first fabric limiting plate 212 and the second fabric limiting plate 213, the first fabric limiting plate 212, the second fabric limiting plate 213, and the connecting plate 21481 form a whole, on the connecting plate 21481 A guide groove for up and down guidance is provided, and the driving slider 21485 is slidably matched with the guide groove in the vertical direction. The driving slider 21485 is hinged with the upper end of the rotating rod 21482, and the lower end of the rotating rod 21482 is fixedly ...

Embodiment 3

[0097] like Figure 13-15 As shown, the difference between this embodiment and the above-mentioned embodiments is: between the primary cloth guiding pipe 13 and the first intermittent cloth storage centralized cloth lowering device 2, the secondary cloth guiding pipe 41 and the second intermittent cloth storage centralized cloth lowering device 3 are also provided with a cloth stretching device 8, and the cloth stretching device 8 is used to spread the cloth 10 falling from the outlet of the corresponding cloth guide pipe.

[0098] The cloth stretching device 8 includes multiple groups of flattening assemblies arranged up and down, each group of flattening assemblies includes a first flattening rod 81, a second flattening rod 82, the lower end of the first flattening rod 81, the second flattening rod The lower end of 82 is rotatably engaged with the housing 71 . The upper end of the first flattening rod 81 and the upper end of the second flattening rod 82 are turned away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com