Preparation method and application of low-density ceramsite proppant added with pretreated electrolytic manganese residues

A technology of electrolytic manganese slag and pretreatment, which is applied in the fields of application, ceramic products, chemical instruments and methods, etc., to achieve the effects of lowering sintering temperature, less crystal phase impurity content, and reducing sintering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

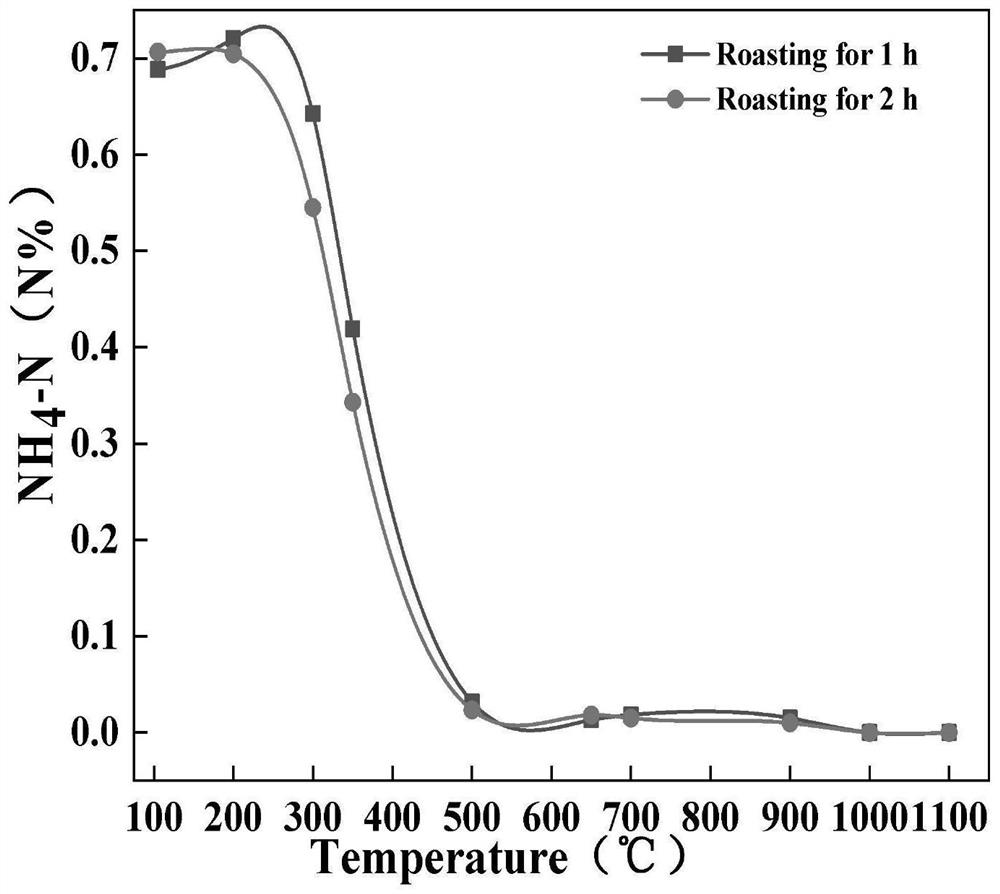

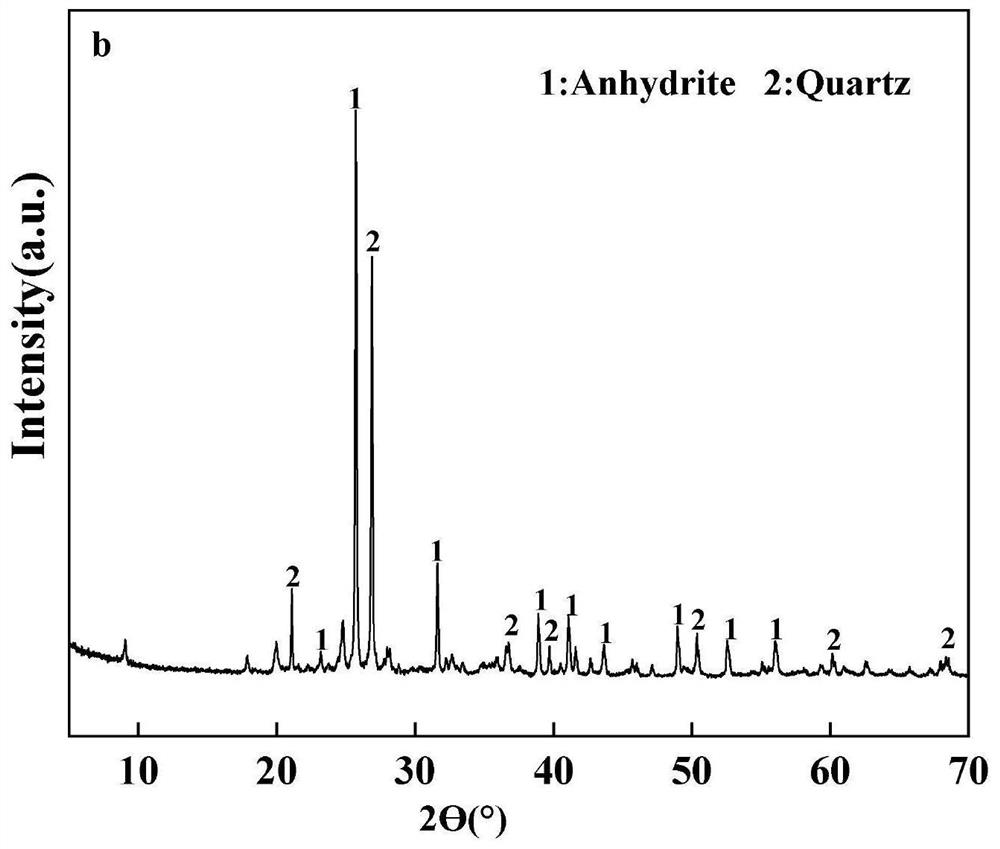

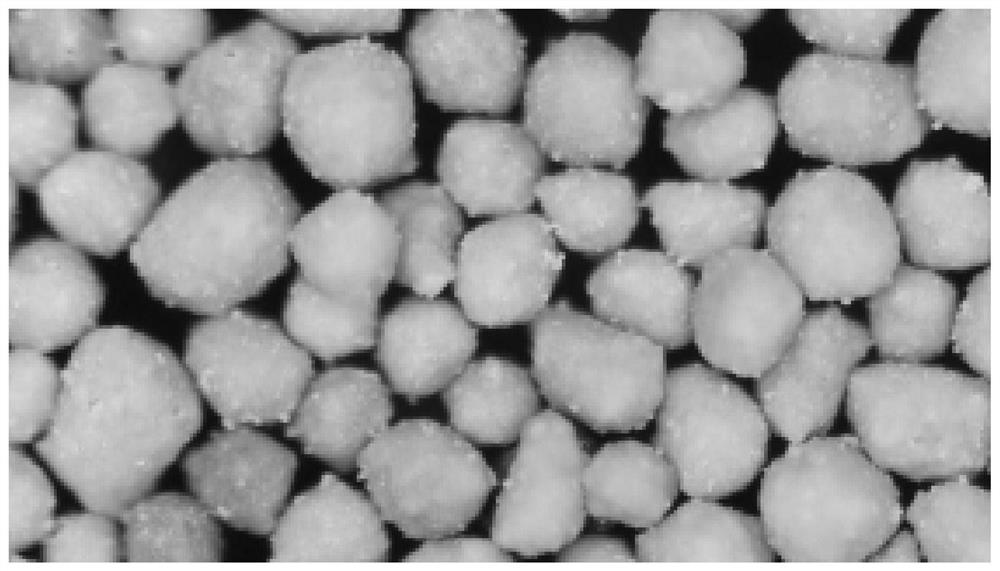

[0038] Example 1. A low-density ceramsite proppant added with pretreated electrolytic manganese slag, the ceramsite proppant is made of the following raw materials: 15 kg of pretreated electrolytic manganese slag and 85 kg of bauxite; the electrolytic manganese slag is industrial waste The residue after the wet extraction of manganese is pretreated by calcination.

[0039] A preparation method and application of a low-density ceramsite proppant added with pretreated electrolytic manganese slag, comprising the following steps:

[0040] (1) Drying and crushing the pretreated electrolytic manganese slag and bauxite, grinding and 300-mesh sieving of the pretreated electrolytic manganese slag and bauxite respectively, the powder particle size is all small 0.048mm, and set aside; In the step (1), the pretreated electrolytic manganese slag contains silicon oxide with a mass fraction of 25-35%, calcium oxide with a mass fraction of 10-25%, and alumina with a mass fraction of 10-15%; ...

Embodiment 2

[0043] Example 2. A low-density ceramsite proppant added with pretreated electrolytic manganese slag, the raw materials are: 20kg of pretreated electrolytic manganese slag and 80kg of bauxite.

[0044] The pretreated electrolytic manganese slag is obtained by calcination at 700°C for 2.5 hours after the wet electrolytic extraction of metal manganese. The pretreated electrolytic manganese slag contains silicon oxide with a mass fraction of 25-35%, calcium oxide with a mass fraction of 10-25%, and aluminum oxide with a mass fraction of 10-15%.

[0045] The preparation steps of the product are:

[0046] (1) drying and crushing the pretreated electrolytic manganese slag and bauxite, and grinding the pretreated electrolytic manganese slag and bauxite respectively, and passing through a 300 mesh sieve to obtain pretreated electrolytic manganese slag powder and bauxite soil powder;

[0047] (2) Mix the pretreated electrolytic manganese slag powder and bauxite powder, add water, st...

Embodiment 3

[0049] Example 3. A low-density ceramsite proppant added with pretreated electrolytic manganese slag, the raw materials are: 18kg of pretreated electrolytic manganese slag and 82kg of bauxite.

[0050] The pretreated electrolytic manganese slag is obtained by calcination at 750°C for 3 hours after the wet electrolytic extraction of metal manganese. The pretreated electrolytic manganese slag contains silicon oxide with a mass fraction of 25-35%, calcium oxide with a mass fraction of 10-25%, and aluminum oxide with a mass fraction of 10-15%.

[0051] The preparation steps of the product are:

[0052] (1) drying and crushing the pretreated electrolytic manganese slag and bauxite, and grinding the pretreated electrolytic manganese slag and bauxite respectively, and passing through a 300 mesh sieve to obtain pretreated electrolytic manganese slag powder and bauxite soil powder;

[0053] (2) Mix the pretreated electrolytic manganese slag powder and the bauxite powder, add the aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com