Injection mold and demolding method

An injection mold and demoulding technology, which is applied in the direction of injection devices, etc., can solve problems such as excessive deformation of injection molded parts, difficulty in demoulding, and unsuitable demoulding treatment for thin-walled injection molded parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

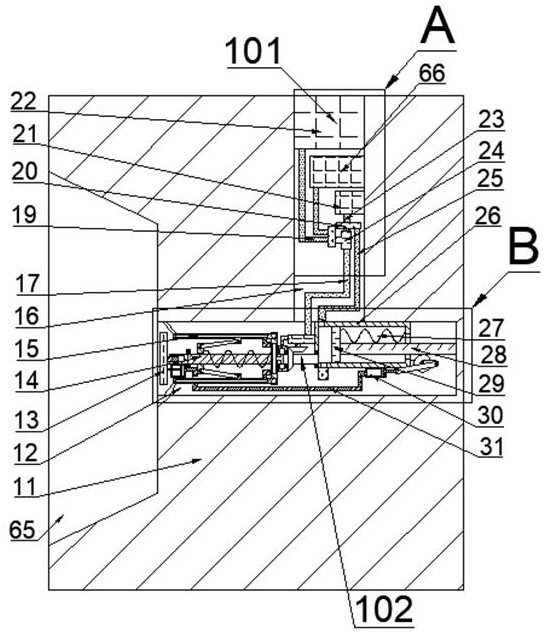

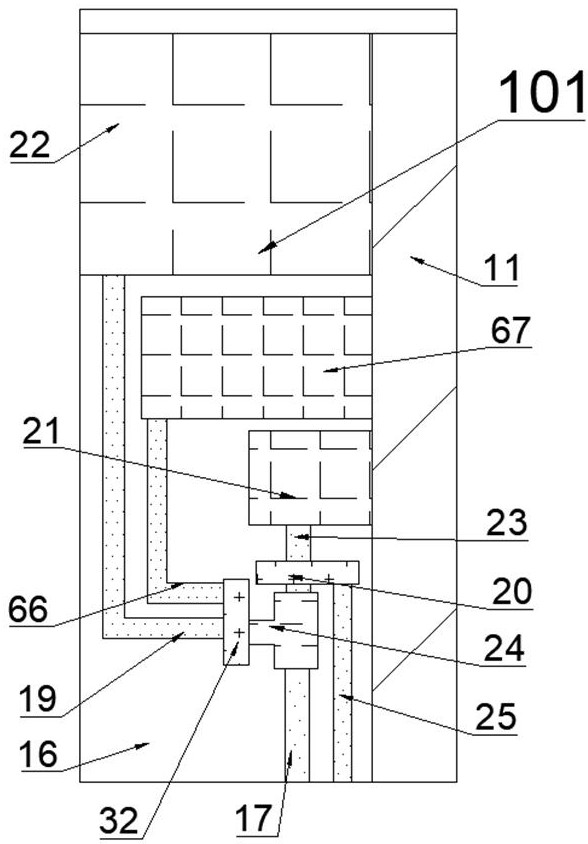

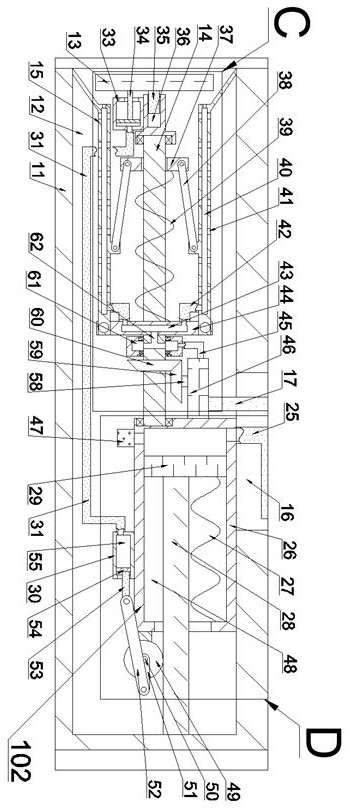

[0023] Bonded below Figure 1 to 5 The present invention will be described in detail, which is convenient, and now, the orientation of the following statement is as follows: The upper and lower directions of the upper and lower directions said below figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0024]One of the injection molds of the present invention includes a mold 11, and an opening is provided with an opening toward the left, and the mold 11 is provided with a push rod in the right side of the recess cavity 65. 12. The push rod cavity 12 is opened toward the left, the mold 11 is provided on the upper side of the push rod cavity 12 and communicating with the push rod cavity 12, and the power chamber 16 is provided The aerodynamic energy supply mechanism 101 is provided with a demolded rust mechanism 102 in which the air movability supply mechanism 101 provides the airflow, rust fluid, and offset of the release rust mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com