Cutting device for steel pipe machining

A technology for cutting devices and steel pipes, applied in pipe shearing devices, shearing devices, metal processing, etc., can solve the problems of cutting finished products that do not meet the requirements, steel pipes that are easy to deviate from the position, time-consuming and labor-intensive failure of steel pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

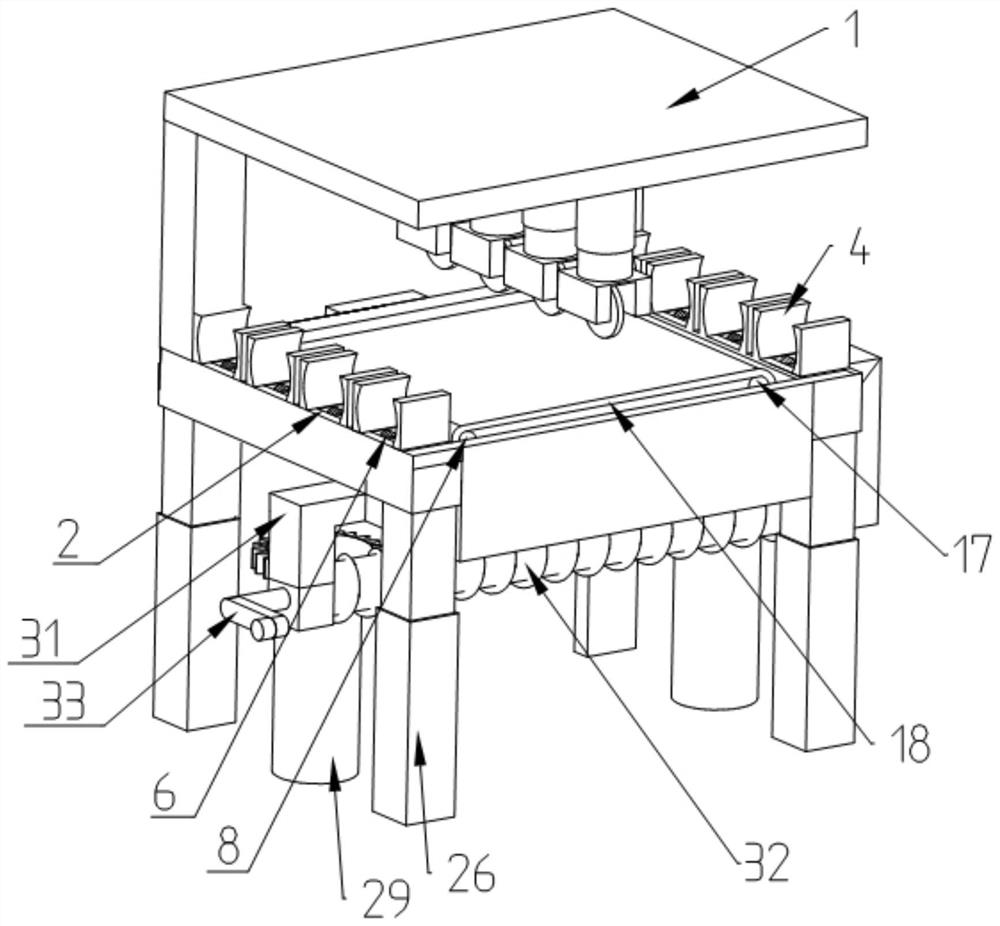

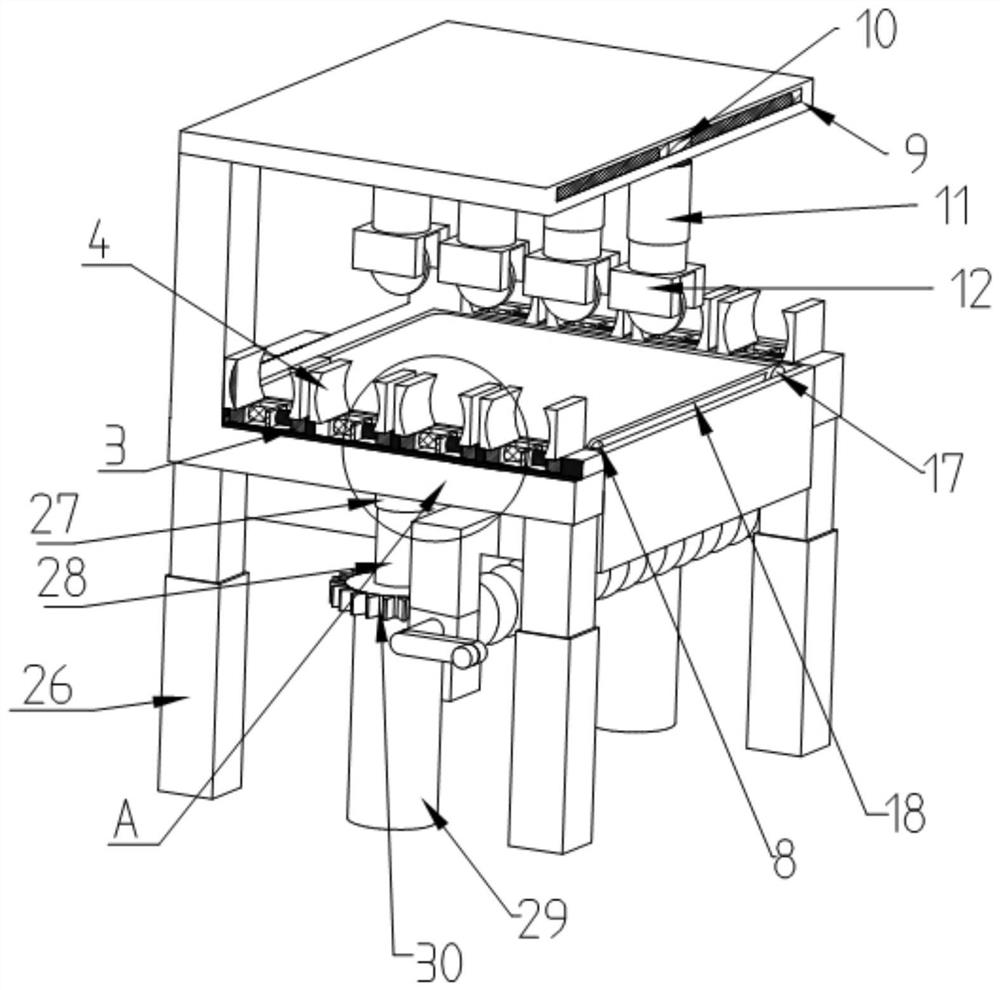

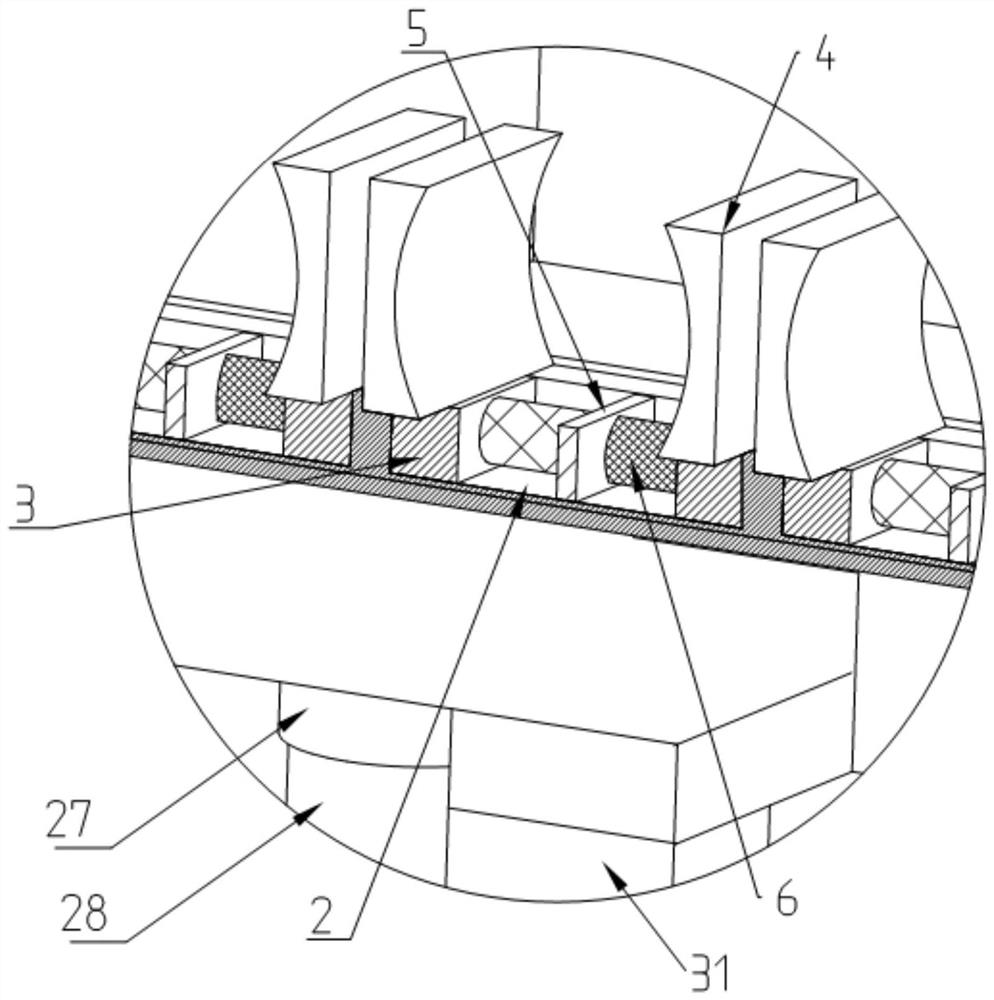

[0029] Such as Figure 1 to Figure 6 As shown, the present invention provides a cutting device for steel pipe processing, including a workbench 1, the left and right ends of the workbench 1 are respectively provided with first moving grooves 2, and the first moving grooves 2 are evenly distributed at the left and right ends of the workbench 1, The front and rear ends of the first moving groove 2 are respectively slidingly connected with a moving block 3, the upper end of the moving block 3 is fixedly connected with a clamping block 4, and the middle part of the first moving groove 2 is fixedly connected with a first fixed block at the middle of two adjacent clamping blocks 4. 5. The upper end of the first fixed block 5 located on the left side of the workbench 1 is equipped with a light emitting and receiving device and a solenoid valve. When the light emitting and receiving device is blocked by an object, when the light emitting and receiving device cannot receive the emitted ...

Embodiment 2

[0046] The applicant found that in the actual production process, steel pipes of different lengths are often required. In order to meet the diversified needs of actual production, the operation process of Example 1 was analyzed. The applicant found that in Example 1, the cut steel pipes The length of the steel pipe is (vt+l). If the rotation speed of the second motor 19 is changed, the transmission speed v of the conveyor belt 18 will also change accordingly. If v changes, (vt+l) will change, thus passing By controlling the transmission speed v, steel pipes with different cutting lengths will be obtained. Therefore, the applicant calculates the required speed v of the second motor 19 according to the required length of the steel pipe, and controls the second motor 19 to make the speed v, Therefore, the length of the steel pipe obtained by cutting is the required length, and the purpose of obtaining steel pipes with different cutting lengths through one instrument is realized. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com