Electric power maintenance safety sign board and using method thereof

A technology for electrical maintenance and sign boards, applied in the field of safety signs, can solve the problems of large road occupation, easy lodging, and easy damage, and achieves the effects of stable structure, not easy to lodging, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

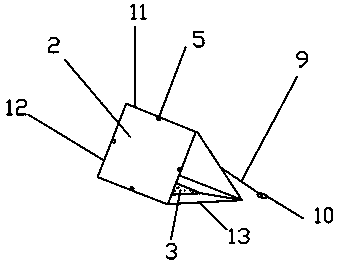

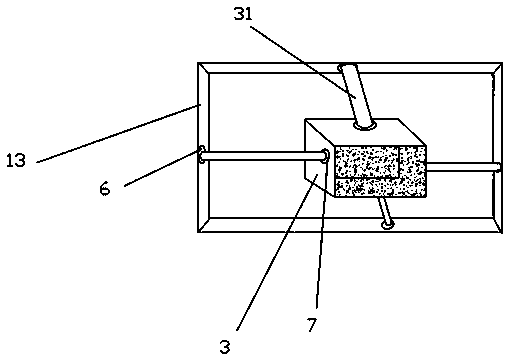

[0042] like Figure 1-5 As shown, a safety signboard for electric maintenance includes a signboard bracket and a signboard 2 fixed on the signboard bracket, and the signboard 2 and the signboard bracket are detachably connected;

[0043] The signboard bracket includes a push rod 11, a side rod 12 connected with the push rod 11 and a bottom rod 13 connected with the side rod 12, the push rod 11 is one, the side rods 12 are four, and the bottom rod 12 is connected with the side rod 12. There are four rods 13, the tops of two side rods 12 are connected with one end of the push rod 11, the tops of the remaining two side rods 12 are connected with the other end of the push rod 11, and the four bottom rods are connected end to end to form a rectangular bottom surface. The bottom ends of the two shown side bars are respectively connected to the four corners of the rectangular bottom surface, and the two side bars 12 located at both ends of the push bar 11 and on the same side are par...

Embodiment 2

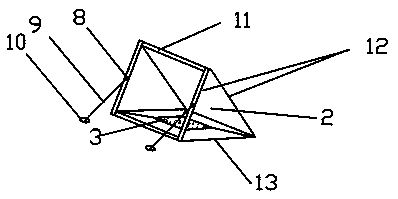

[0056] like Figure 1-2 As shown in and 3-6, a safety signboard for electric maintenance includes a signboard bracket and a signboard 2 fixed on the signboard bracket, and the signboard 2 and the signboard bracket are detachably connected;

[0057] The signboard bracket includes a push rod 11, a side rod 12 connected with the push rod 11 and a bottom rod 13 connected with the side rod 12, the push rod 11 is one, the side rods 12 are four, and the bottom rod 12 is connected with the side rod 12. There are four rods 13, the tops of two side rods 12 are connected with one end of the push rod 11, the tops of the remaining two side rods 12 are connected with the other end of the push rod 11, and the four bottom rods are connected end to end to form a rectangular bottom surface. The bottom ends of the two shown side bars are respectively connected to the four corners of the rectangular bottom surface, and the two side bars 12 located at both ends of the push bar 11 and on the same s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com