Discharging and screening device for metal powder grinding

A technology of metal powder and discharge device, which is applied in the field of metal processing and can solve problems such as metal powder loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

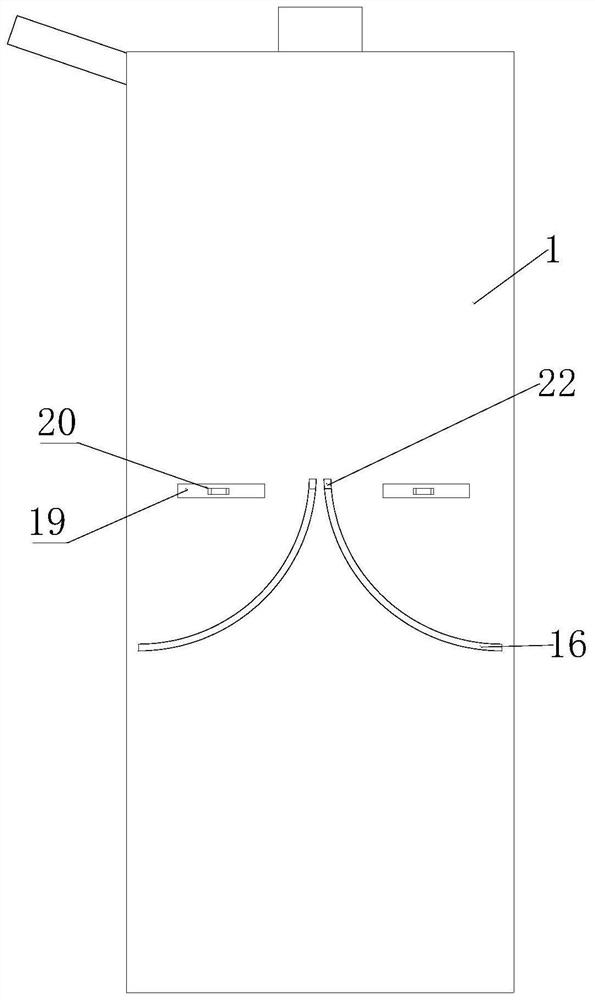

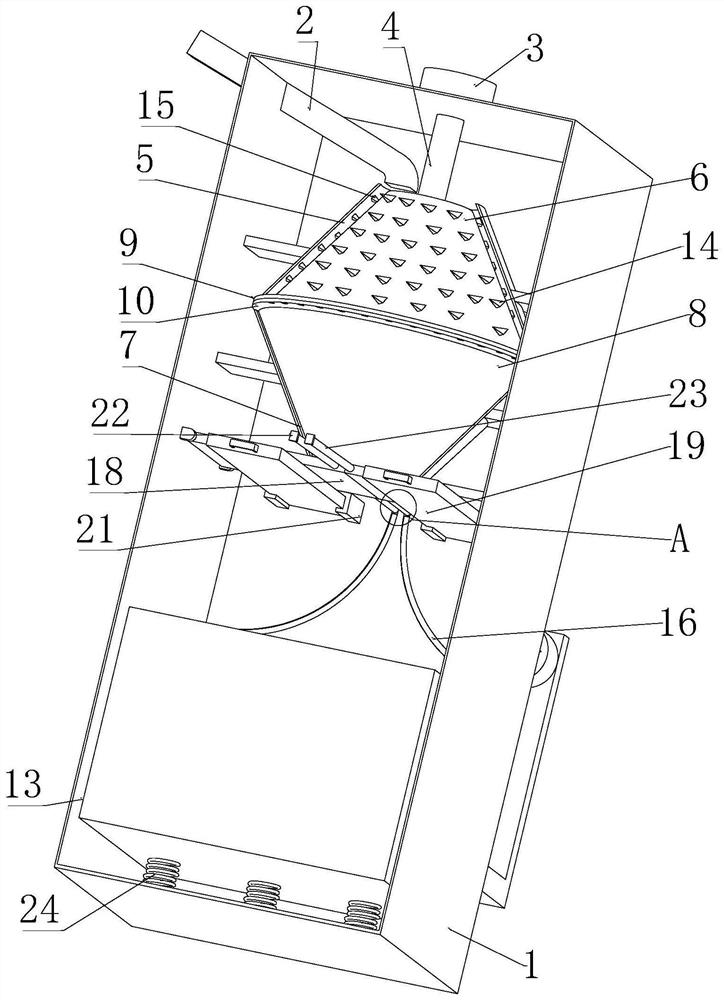

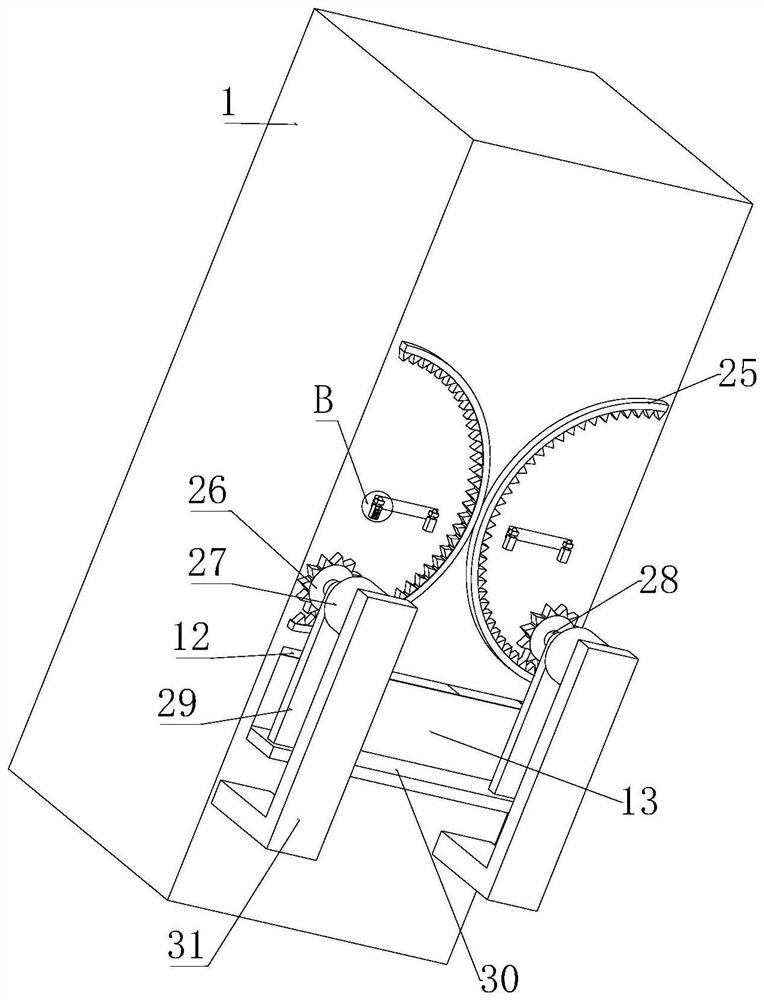

[0031] A discharge screening device for metal powder grinding, comprising a box body 1, a discharge device and a screening device, the discharge device includes two discharge plates 18, the front and rear sides of the two discharge plates 18 pass through movable shafts respectively Rotationally connected on the inner walls of the left and right sides of the box body 1, the two discharge plates 18 are provided with a drive device for the discharge plate at one end close to each other, and the bottoms of the two discharge plates 18 are provided with a supporting device.

[0032]Further, the driving device of the discharge plate includes four connecting rods 23, and the four connecting rods 23 are fixedly installed on the ends of the two discharge plates 18, which are close to each other. A quarter arc-shaped through-slot 16, four connecting rods 23 are fixedly connected to a slider 22 on the side away from the discharge plate 18, and the slider 22 is slidably connected to the cor...

Embodiment 2

[0039] As an optional situation, a crushing device is provided above the grinding device, and the crushing device includes a crushing shell 5, which is fixedly installed above the casing 1, and a rotating block 6 is arranged in the crushing shell 5 to crush A plurality of second grinding teeth 15 are evenly distributed on the inner wall of the housing 5 , and a plurality of first grinding teeth 14 are evenly distributed on the side of the rotating block 6 .

[0040] Grinding device, the grinding device comprises a grinding shell 7, the grinding shell 7 is fixedly installed in the casing 1, the grinding shell 7 is located below the crushing shell 5, and the grinding shell 7 is provided with a grinding block 8, and the rotating block 6 and A rotating device is provided between the grinding blocks 8 , a feeding device is provided between the crushing shell 5 and the grinding shell 7 , and the bottom of the grinding shell 7 is offset against the tops of the two discharge plates 18 ...

Embodiment 3

[0048] As an optional situation, the support device includes two backing plates 19, the two backing plates 19 are respectively located under the two discharge plates 18, and the two backing plates 19 are respectively against the bottoms of the two discharge plates 18, The front ends of the two backing plates 19 run through the front side of the box body 1, and four guide rails 21 are fixedly connected on the inner walls of the front side and the rear side of the box body 1, and the four guide rails 21 are matched with the backing plate 19. The two backing plates 19 are plugged into the corresponding guide rails 21 respectively, and the guide rails 21 limit the positions of the two backing plates 19, so that the two backing plates 19 respectively support the bottoms of the two discharge plates 18 to prevent the two The two discharge plates 18 are separated, the rear ends of the two backing plates 19 pass through the rear side of the box body 1, and a fixing device is provided be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com