Copper foil gluing and rolling integrated equipment and implementation mode

A technology of gluing and copper foil, which is applied to the device, coating, pretreatment surface, etc. of coating liquid on the surface, which can solve the problems of affecting the production quality of copper foil, colloid dripping, and uneven brushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 1 Embodiment approach

[0038] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, an embodiment of an integrated copper foil gluing and winding device, which includes the following steps:

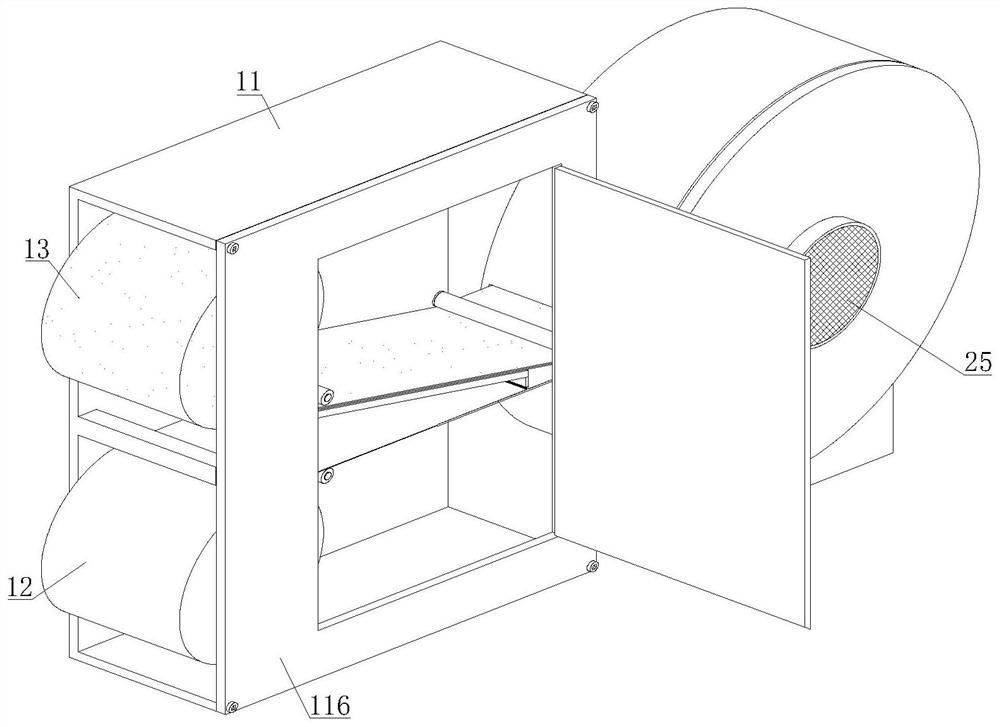

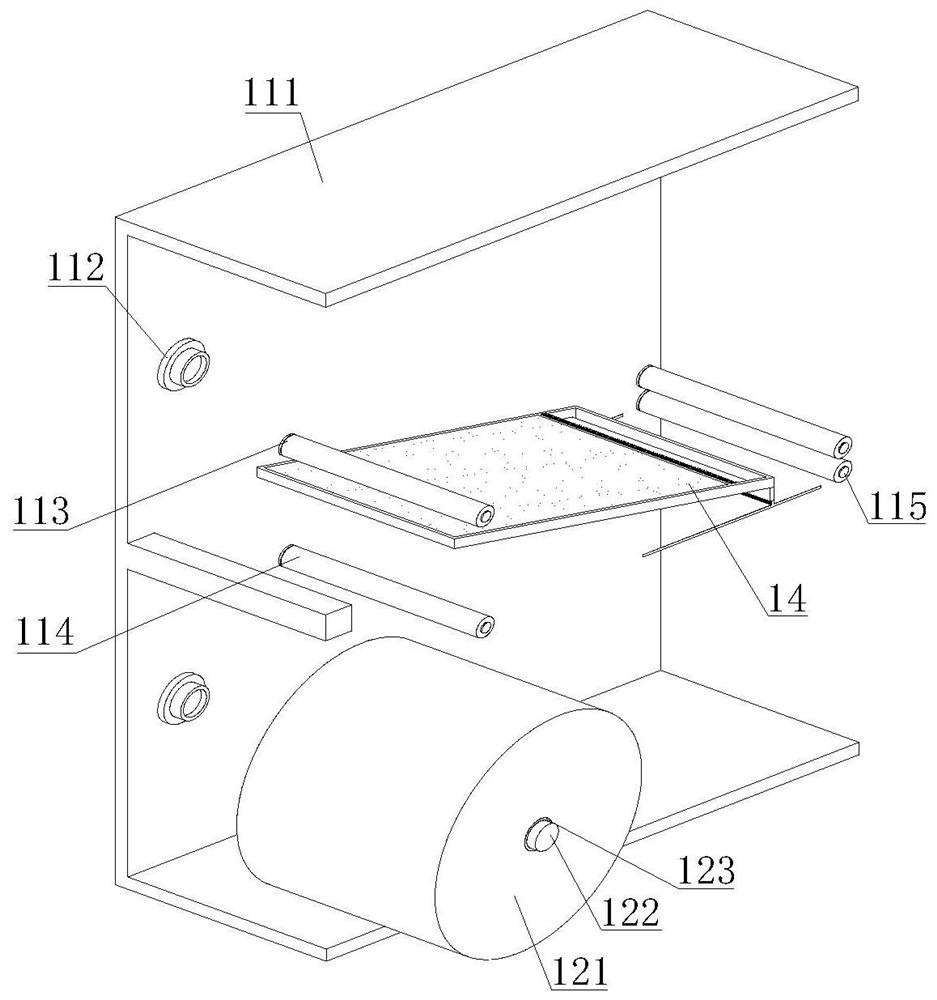

[0039] Step 1: Fix the copper foil component 12 and the colloid component 13 on the side of the inner cavity of the box body 11 by clamping the telescopic rod 112, and then clamp the copper foil component 12 and the colloid component 13 at the winding port by the traction block 223 During the clamping and traction process, the copper foil assembly 12 and the colloid assembly 13 are respectively guided by the second guide roller 114 and the first guide roller 113, and cooperate with the repressing roller set 115 to keep the copper foil assembly 12 horizontal state, the colloid assembly 13 remains in a tilted state;

[0040] Step 2: While the colloid assembly 13 is kept in a tilted state, the bottom surface of the filling layer 132 is in contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com