Rapid wheat cleaning facility

A fast and facility technology, applied in application, grain processing, grain milling, etc., can solve the problems of excessive wheat moisture content, non-circulating operation, and uneven humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

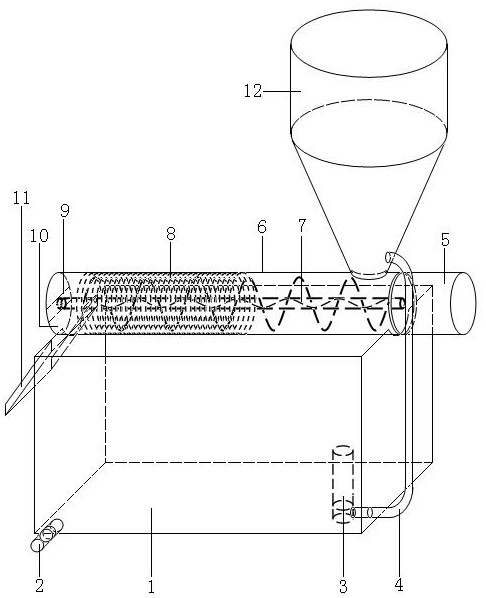

[0016] Now describe in detail the shape and structure of the present invention in conjunction with accompanying drawings and reference numerals:

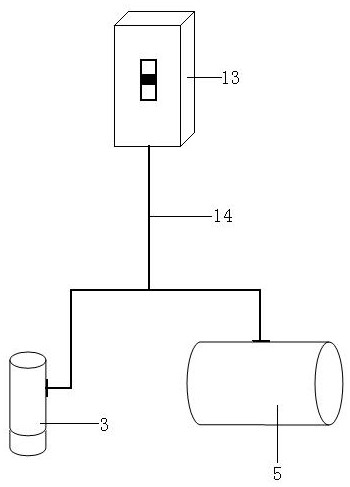

[0017] A quick cleaning facility for wheat, characterized in that it includes a water tank 1, a drain valve 2, a water pump (AC380V / 0.5-1.5kw) 3, a water pipe 4, a geared motor (AC380V / 1-3kw) 5, a cleaning cylinder 6, and a propeller 7. Sewage pipe 8, bracket 9, outlet 10, chute 11, silo 12, power switch (AC380V / 20A) 13, power cord 14;

[0018] The water tank 1 is in the shape of a hollow cuboid, with an opening at the top, a circular drainage valve 2 is arranged at the bottom of the front, and a semicircular installation groove is respectively arranged at the center of both sides above;

[0019] The cleaning cylinder 6 is hollow cylindrical, the left side is connected to the right side of the sewage pipe 8 to form a whole, and the right side of the cleaning cylinder 6 and the left side of the sewage pipe 8 are connected to the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com