Connector process assembly line and production method thereof

A connector and assembly line technology, which is applied to the connector process line and its production field, can solve the problems of unstable quality, low production efficiency, heating injection molding raw materials, etc., to improve current conduction performance, improve production efficiency, and ensure stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

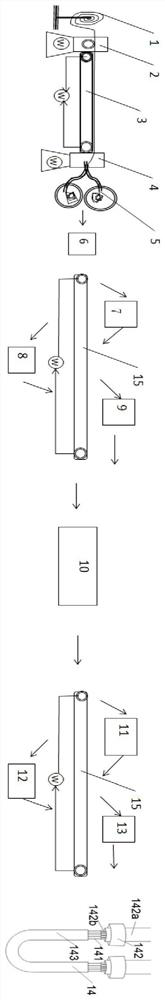

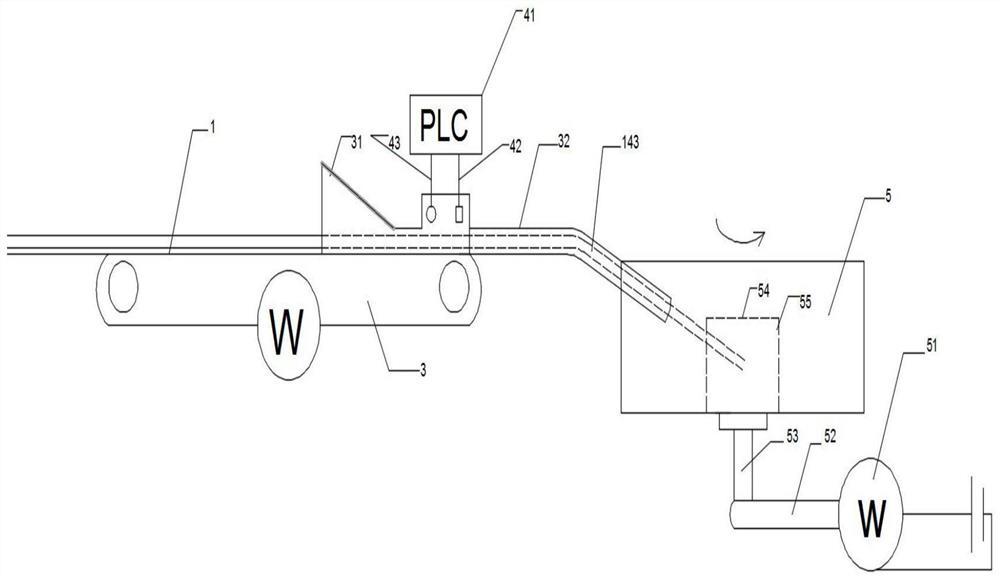

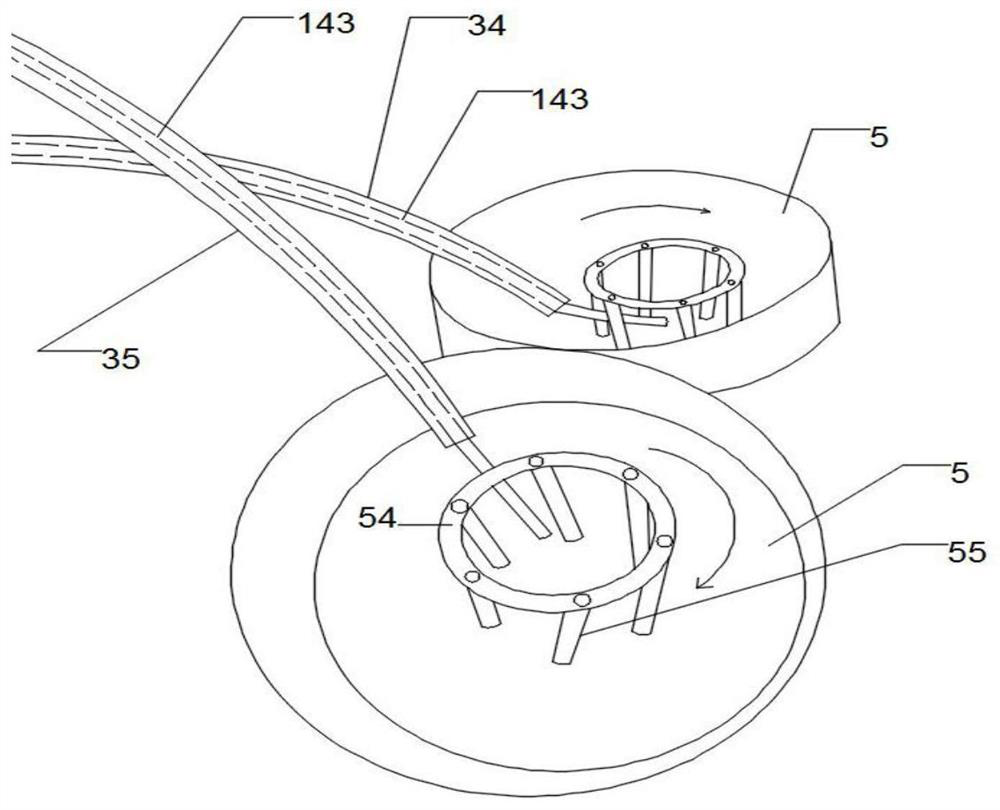

[0035] refer to Figure 1-8 , a connector process line and its production method are proposed in this embodiment

[0036] Such as figure 1 Shown: a connector process line, including a cable (1), a double-wire cutting and winding system, a rotating double-sided soldering system, a double-wire protective injection molding system (10), an on-off high-voltage test device (11), a sticker Marking device (12), packaging device (13) and connector (14), wherein connector (14) comprises cable segment (143), connector plug (142) and cable segment (143) two sections of wire ends ( 141), one end of the connector plug (142) is a circular cavity (142a), and the other end is an intubation tube (142b), which is characterized in that: after the double cable (1) passes through the double-wire cutting and winding system, it is transported by the transmission belt ( 15) Transfer to the rotating double-sided soldering system. After completing the double-sided soldering of the cable segment (143) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com