Schottky diode and preparation method thereof

A technology of Schottky diodes and doped layers, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as low on-resistance of on-channel channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

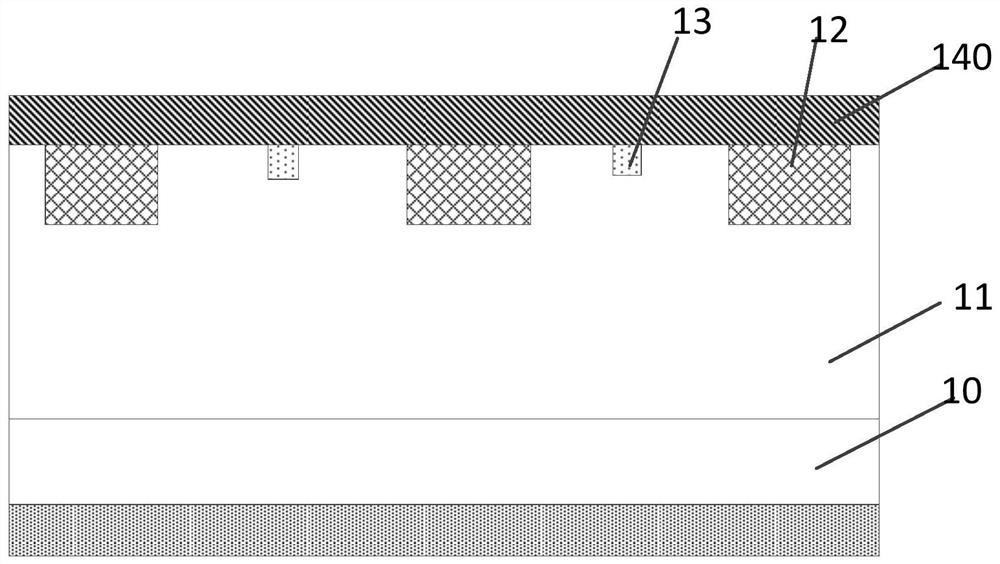

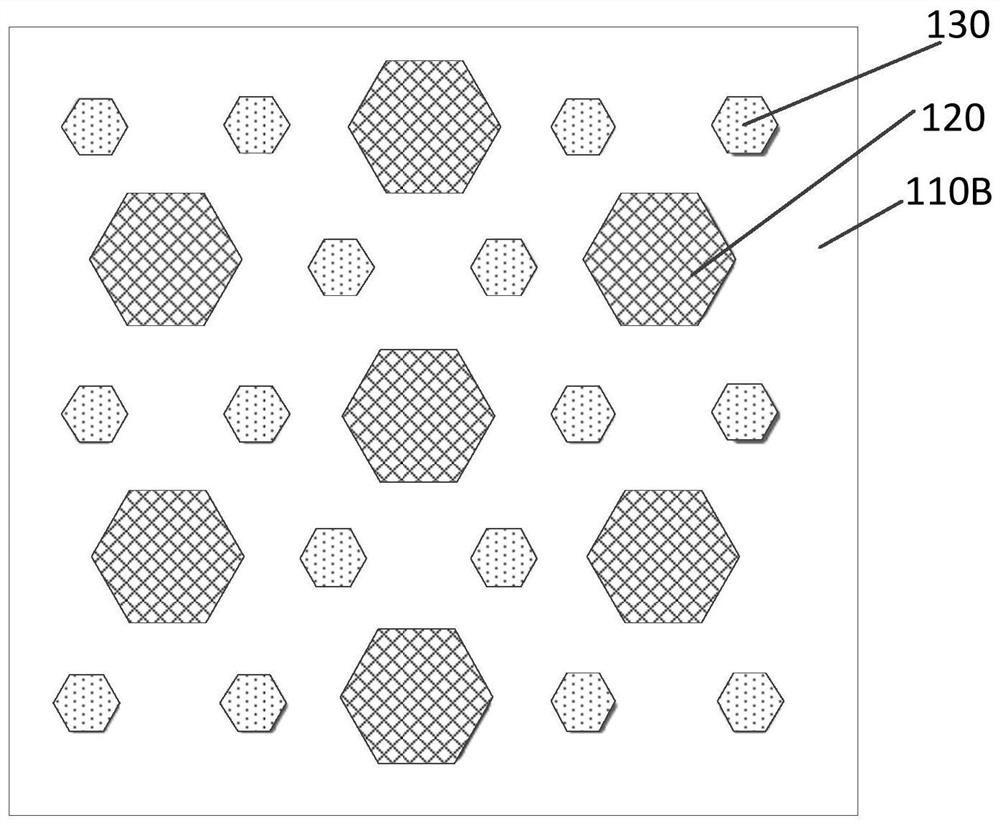

[0074] Correspondingly, another embodiment of the present invention also provides a method for preparing a Schottky diode, referring to Figure 6 , including the following steps:

[0075] S01: providing a semiconductor substrate layer;

[0076] S02: forming a drift layer on the semiconductor substrate layer, the drift layer includes a first drift region and a second drift region located on the side of the first drift region facing away from the semiconductor substrate layer, the second drift region a doping concentration greater than that of the first drift region;

[0077] S03: forming a sub-doped layer in part of the second drift region, the conductivity type of the sub-doped layer is opposite to the conductivity type of the drift layer;

[0078] S04: Form several main doped layers in the drift layer, several main doped layers are spaced around the sub-doped layer, the conductivity type of the main doped layer is the same as the conductivity type of the sub-doped layer . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com