Method for prolonging fatigue life of complex structure of crude oil transfer barge

A technology with complex structure and fatigue life, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of cracks and fatigue damage, large stress concentration, short fatigue life of all random loads, etc., to improve fatigue strength , Improve the effect of fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the examples of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the examples of the present invention. Obviously, the described examples are only some examples of the present invention, not all examples.

[0027] It is difficult to obtain accurate and intuitive detection results directly by traditional ultrasonic testing for metal parts manufactured by composite additives. Therefore, it is first necessary to analyze the attenuation characteristics of ultrasonic waves inside the metal parts, and use advanced ultrasonic testing methods for its attenuation laws. Therefore, it is of great significance to study effective ultrasonic testing methods to achieve accurate evaluation of various internal defects.

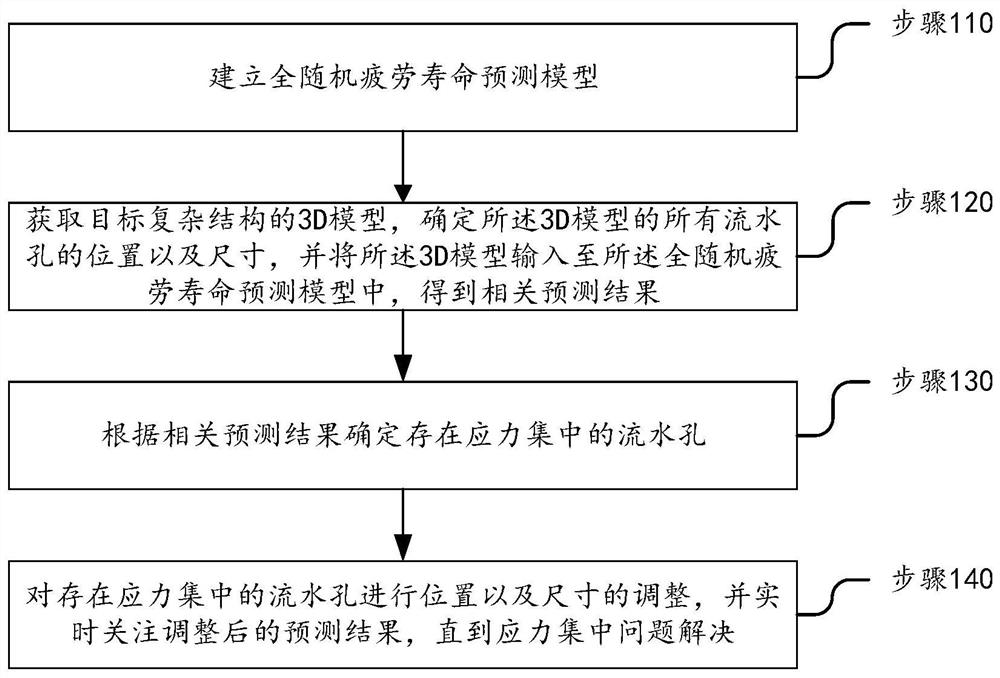

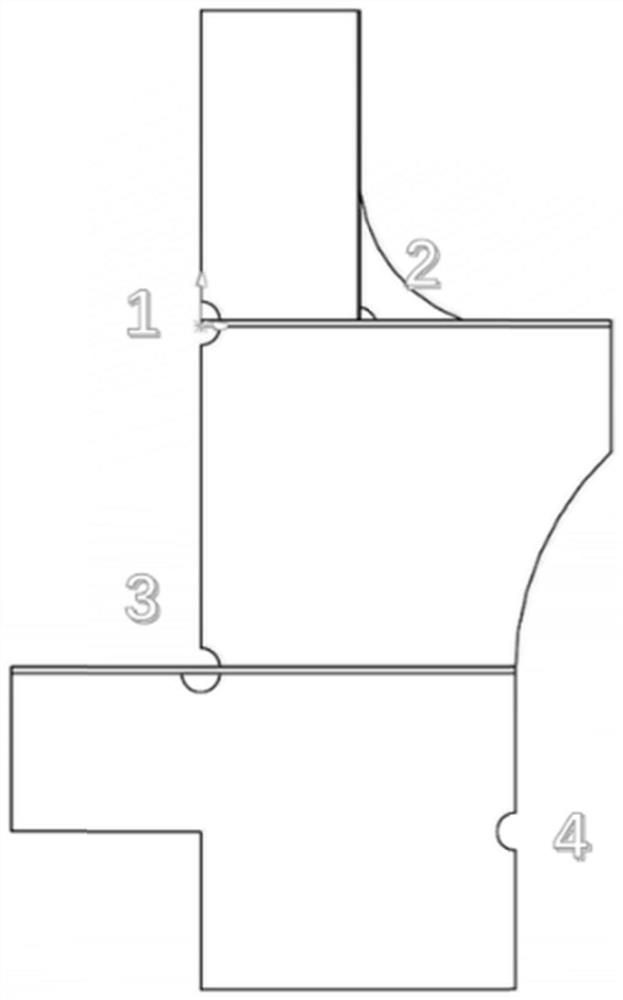

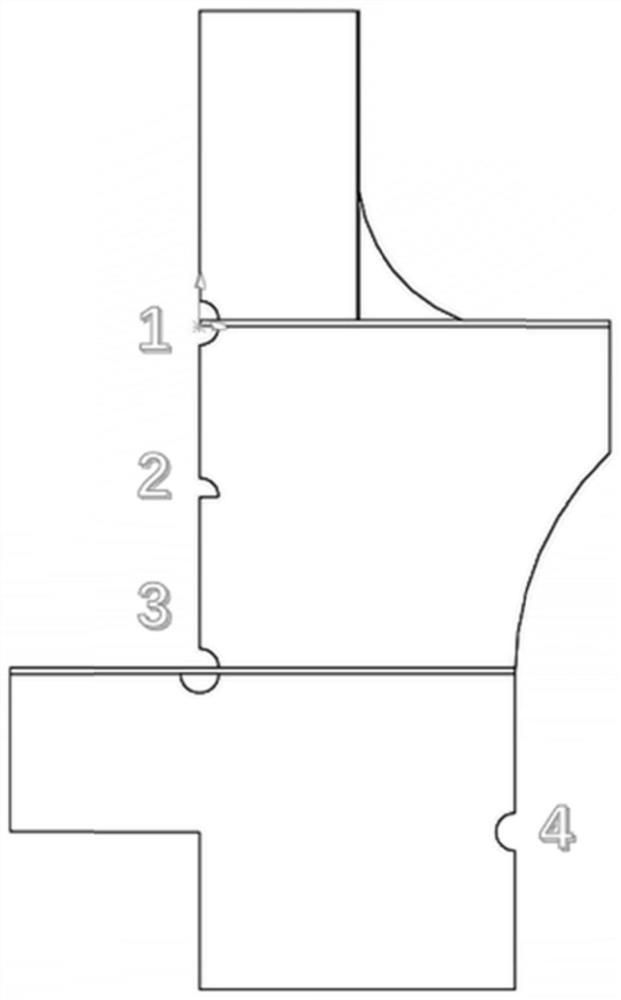

[0028] combine figure 1 as well as Figure 5 , embodiment 1, is a kind of method that the present invention proposes and improves the complex structure fatigue life of crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com