A control method for improving the flexibility of coal-fired units through high steam extraction and throttling

A technology for a coal-fired unit and a control method, which is applied to the combustion method, the general control system, and the regulation of fuel supply, etc., can solve the problems of increased flue gas flow, low temperature of the working fluid at the outlet of the water wall, and large heat storage, etc., and achieves improvement. The effect of temperature control quality, simple realization method and short recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

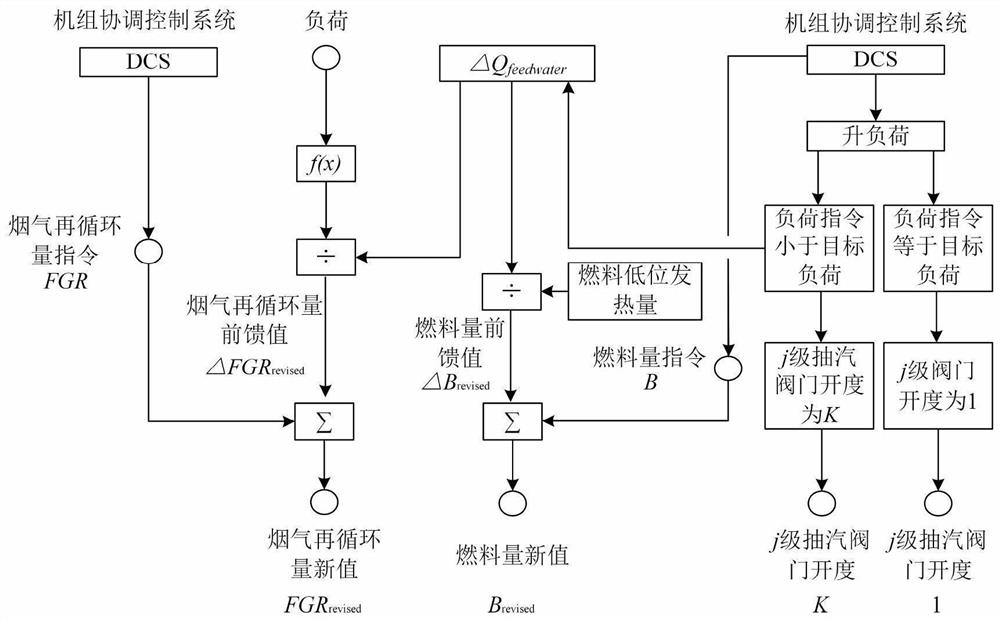

[0045] The present invention is a control method for improving the flexibility of a coal-fired unit through high steam extraction and throttling. The secondary reheat unit is selected as the research object, and the j-level steam extraction is selected as the ultra-high pressure cylinder extraction. like figure 1 As shown, the specific implementation method is as follows: After the coal-fired unit receives the load increase command, it reduces the opening of the j-level extraction valve corresponding to the j-level high increase to K, and after the load command reaches the target load, the j-level extraction valve At the same time, the feedwater heat absorption change caused by the reduction of the j-stage extraction valve opening in the transient process and the low-level calorific value of the fuel are used as the feed-forward value of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com