Method for separating and detecting related substances of 1-butylsulfonyl chloride

A technology for butylsulfonyl chloride and related substances, which is applied in the field of separation and detection of 1-butylsulfonyl chloride related substances, and achieves the effects of rapid derivatization reaction, less corrosion and less reaction by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] S1: Sample preparation:

[0045] 1. Preparation of the test solution: Take about 125mg of 1-butylsulfonyl chloride test product, weigh it accurately, add 3ml of dichloromethane, shake well, add 0.4ml of diethylamine, vortex for 1min, add dichloromethane Dissolve and dilute to 25ml. Accurately measure 10ml, add 5ml of water, shake for 1min, take 10ml of the organic layer, add an appropriate amount of anhydrous sodium sulfate (about 1g), remove water, and take the supernatant as the test solution.

[0046] 2. Blank solution: do not add the 1-butylsulfonyl chloride test product, and prepare a blank solution according to the preparation method of the test product solution.

[0047] 3. System suitability solution:

[0048] 1-Butylsulfonyl chloride derivative stock solution, ethylsulfonyl chloride derivative stock solution, propylsulfonyl chloride derivative stock solution, pentanesulfonyl chloride derivative stock solution, hexylsulfonyl chloride derivative stock solution:...

Embodiment 2

[0065] 2.1 Specificity

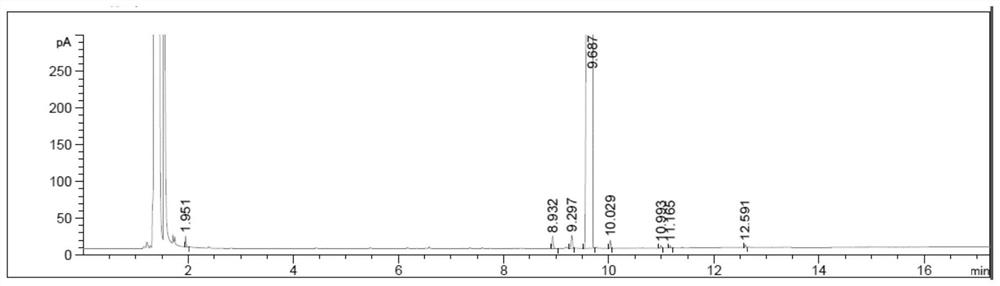

[0066] Measure 1 μl of the system suitability solution, blank solution and test solution respectively, and inject them into the gas chromatograph for detection. The gas chromatogram is as follows: Figure 1~3 shown by the spectrum Figure 1~3 It can be seen that the blank solution does not interfere with the determination of 1-butylsulfonyl chloride and various impurities, and the resolution between 1-butylsulfonyl chloride and various impurities is greater than 2.0, which is good and meets the requirements.

[0067] 2.2 Linear range and correction factor, detection limit and quantification limit

[0068] Take 1-butylsulfonyl chloride derivative stock solution, ethylsulfonyl chloride derivative stock solution, propylsulfonyl chloride derivative stock solution, pentanesulfonyl chloride derivative stock solution, hexylsulfonyl chloride derivative stock solution, 1,2 -Dichloroethane stock solution, 1-bromobutane stock solution, and butyl thiocyanate sto...

Embodiment 3

[0082] Chromatographic conditions:

[0083] Chromatograph: Agilent 7890B

[0084] Detector: Hydrogen Flame Ionization Detector (FID)

[0085] Chromatographic column: HP-5 capillary column (30m×0.320mm×0.25μm);

[0086] Injection port temperature: 210°C;

[0087] Detector temperature: 240°C;

[0088] Carrier gas flow rate: 1.8ml / min;

[0089] Split ratio: 4:1;

[0090] Injection volume: 1μl;

[0091] Programmable temperature rise: the initial temperature is 33°C, maintained for 2 minutes, then raised to 215°C at a rate of 18°C / min, maintained for 7 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com