Bolt corrosion test fixing device

A corrosion test and fixing device technology, applied in the field of surface engineering, can solve problems such as the inability to guarantee the fixed angle of placement, the inability to simulate the corrosion situation, and the excess function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

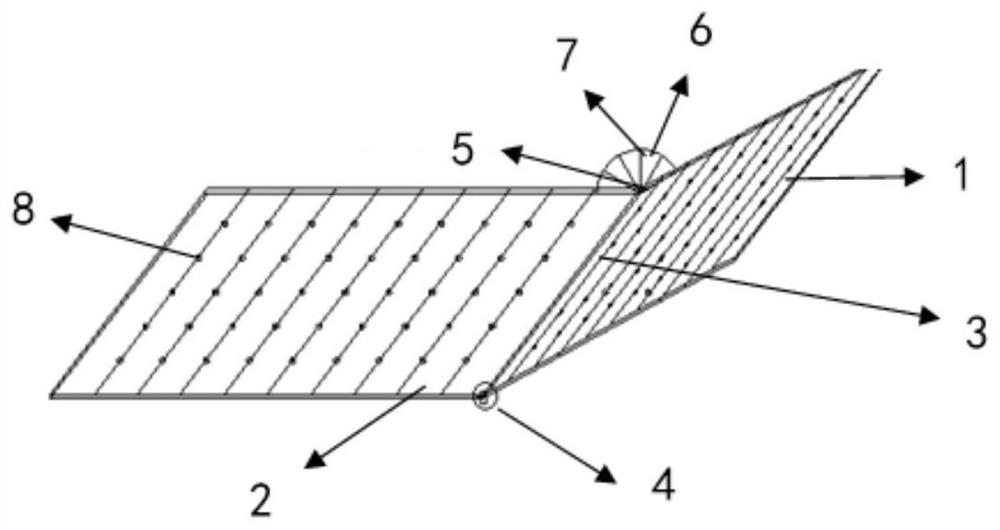

[0044] like figure 1 As shown, a bolt corrosion test fixing device includes a No. 1 load plate 1, a No. 2 load plate 2, a rotating shaft 3, and a protractor 6. A number of bolt fixing holes 8 are respectively arranged on the No. 1 load plate 1 and the No. 2 load plate 2. , the rotating shaft 3 is fixed on one end of the No. 1 loading plate 1, and the No. 2 loading plate 2 is hinged to the rotating shaft to realize the relative rotation between the No. 1 loading plate 1 and the No. 2 loading plate 2. The protractor 6 is fixed on the front side of the No. 6. The center of the circle is coaxial with the center of the rotating shaft 3. The two ends of the rotating shaft 3 are coaxially fixed with a No. 1 knob 4 and a No. 2 knob 5, and a pointer 7 is coaxially fixed on the No. 2 knob 5.

[0045] The hole diameters of several bolt fixing holes 8 provided on the No. 1 bearing plate 1 and the No. 2 bearing plate 2 are not completely the same.

[0046] The bolt fixing holes 8 provided...

Embodiment 2

[0050] A kind of corrosion test equipment, it comprises the bolt corrosion test fixing device described in embodiment 1 and horizontal frame, support rod, and bolt corrosion test fixing device is placed on the horizontal frame and supported by the support rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com