Monitoring and repairing characterization method for self-repairing concrete engineering crack

A concrete, self-healing technology, applied to measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc. Convenient, easy-to-apply effects

Inactive Publication Date: 2021-06-04

POWERCHINA RAILWAY CONSTR +1

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Purpose of the invention: In view of the lack of methods for monitoring the generation of cracks and the repair process of cracks at the current engineering site, the present invention provides a method for monitoring and repairing characterization of cracks in self-repairing concrete engineering

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0034] The invention of the present invention is used to detect and repair the cracks in the self-repairing concrete engineering of a certain engineering site, and the specific process is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

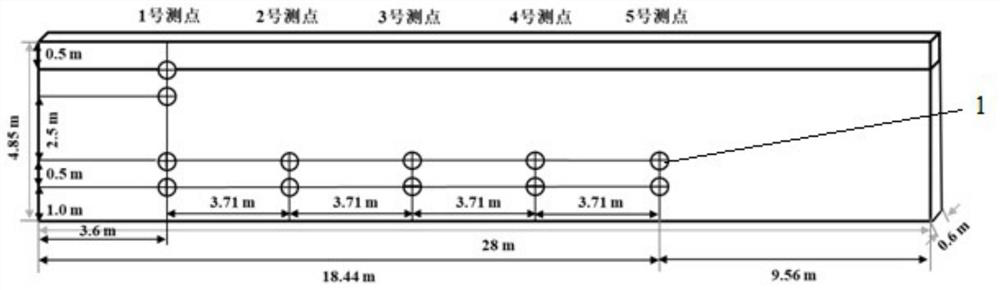

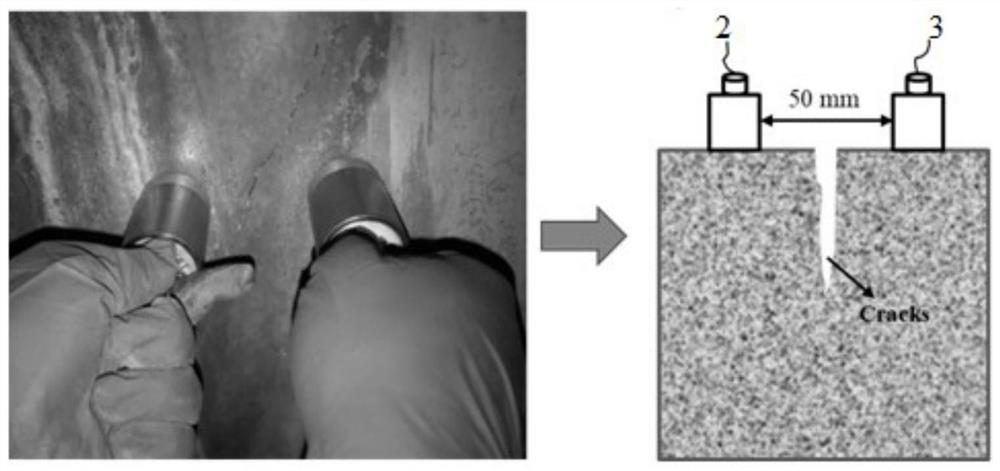

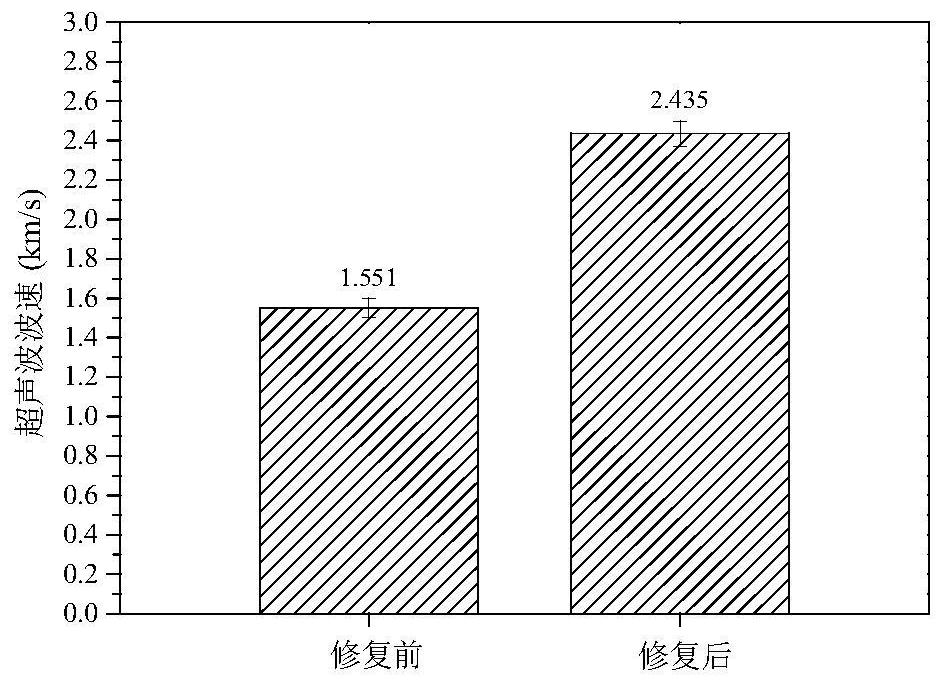

The invention discloses a monitoring and repairing characterization method for a self-repairing concrete engineering crack which comprises the following steps: (1) in the process of pouring self-repairing concrete in an engineering site, embedding a sensor in the self-repairing concrete to obtain temperature and micro-stress data in the self-repairing concrete at different pouring time, and judging the generation position of the crack accordingly; and (2) after the crack is generated, testing the concrete crack at different repairing times by adopting an ultrasonic method, and representing the self-repairing condition of the crack by virtue of the change of the ultrasonic wave velocity. According to the invention, the crack monitoring and repairing characterization method for the engineering site is provided for the first time, by adopting the method, the generation position of the crack can be rapidly and accurately detected by observing and analyzing the temperature and strain data in the concrete, and meanwhile, the repairing condition of the concrete crack can be conveniently and accurately characterized by utilizing an ultrasonic method; in addition, the method depends on a simple test tool and is convenient to apply in an engineering field.

Description

technical field [0001] The invention relates to a monitoring and repairing characterization method for self-repairing concrete engineering cracks, belonging to the field of concrete crack monitoring. Background technique [0002] In the field of civil engineering and construction, concrete is the most widely used material. However, due to the shortcomings of concrete materials such as high brittleness, low tensile strength and large shrinkage deformation, different types of microscopic cracks will inevitably occur on the surface during its long-term service. Cracks seriously reduce the bearing capacity of the structure and affect the functionality and aesthetics of concrete materials. Therefore, timely and efficient repair of concrete cracks can not only improve the service life of concrete structures, but also save maintenance costs and reduce economic losses. [0003] Self-healing concrete is a new type of concrete with self-healing function. When cracks occur, it can acc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01D21/02G01N29/07

CPCG01D21/02G01N29/07G01N2291/011G01N2291/0232G01N2291/0289

Inventor 钱春香郭建强韩向朝赵连军郑天文王成王大鹏潘毅李晓东张道波陈浩潘岩峰

Owner POWERCHINA RAILWAY CONSTR

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com