Drainage pipeline flow limiting adjusting device

The technology of a regulating device and a drainage pipeline is applied in the field of water supply and drainage, which can solve the problems of high cost, difficult assembly, complicated structure of the regulating valve, etc., and achieve the effect of reducing engineering cost and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

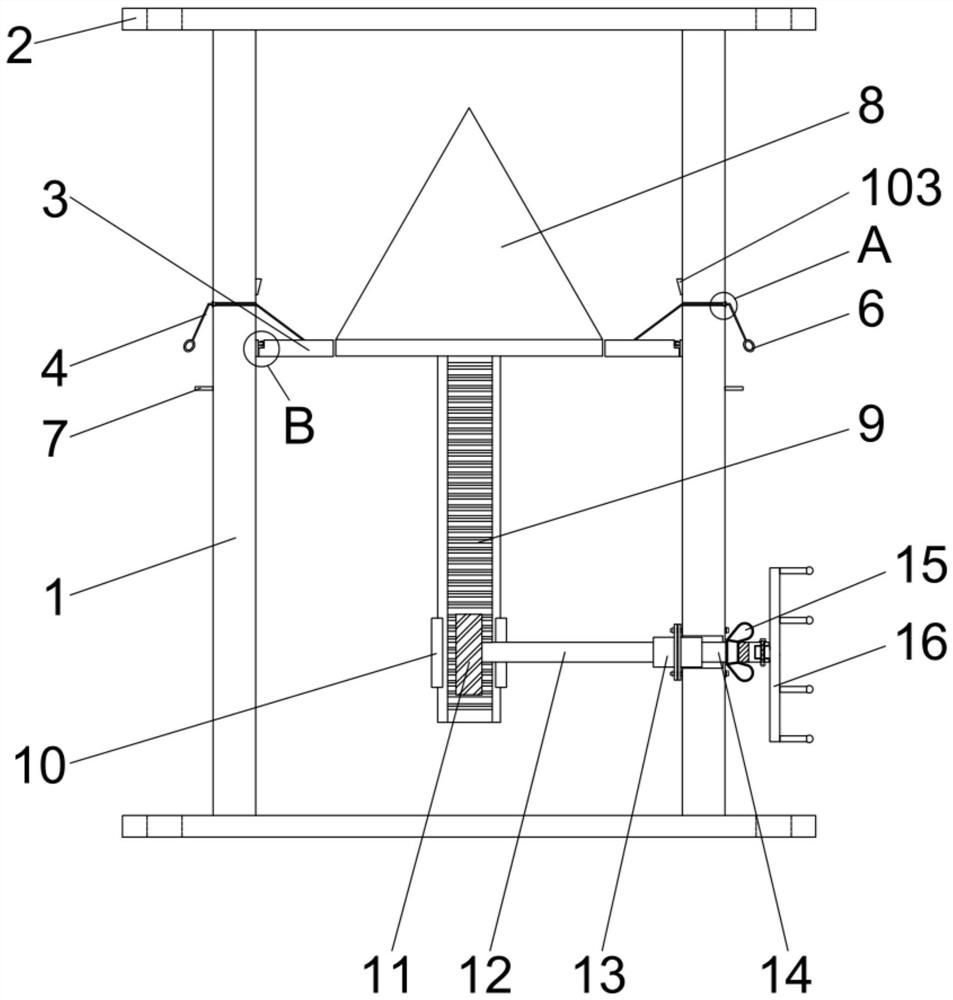

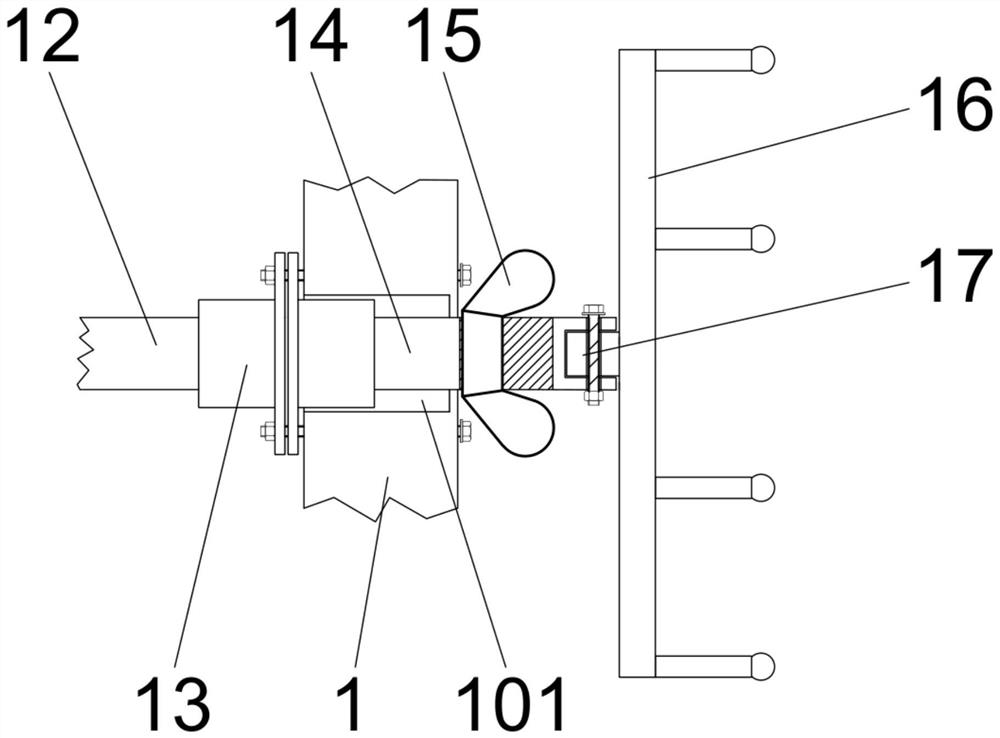

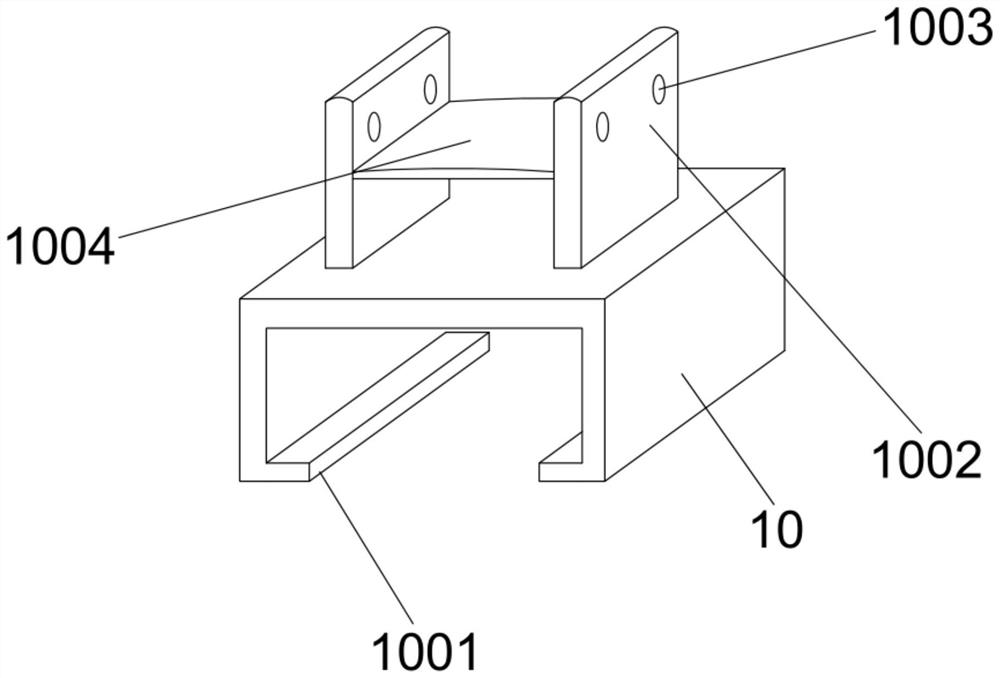

[0026] Embodiment 1: a kind of drain pipe flow limiting adjustment device, such as figure 1 As shown, including the steel pipe 1, the upper and lower ends of the steel pipe 1 are welded with flange plates 2, the interior of the steel pipe 1 is provided with an annular baffle 3, the baffle 3 and the inner wall of the steel pipe 1 are perpendicular to each other, and the middle of the annular baffle 3 Form water holes.

[0027] Such as Figure 6 As shown, the annular baffle plate 3 is mainly composed of four arc-shaped plates of the same size. In order to facilitate the installation of each component, the steel pipe 1 itself can be finally welded by using four arc-shaped steel plates (the number of arc-shaped steel plates is preferably the same as The number of arc-shaped plates is the same), and an arc-shaped plate is installed on each arc-shaped steel plate.

[0028] The wall of the steel pipe 1 is provided with a wire hole 102 for the steel wire 4 to pass through, such as ...

Embodiment 2

[0039] Embodiment 2: A drainage pipe current limiting adjustment device, including a steel pipe 1, the upper and lower ends of the steel pipe 1 are welded with flange plates 2, the interior of the steel pipe 1 is provided with an annular baffle 3, the baffle 3 and the steel pipe 1 The inner walls are perpendicular to each other, and the middle part of the annular baffle plate 3 forms a water hole. The annular baffle plate 3 is a whole annular plate, and the annular baffle plate 3 is welded to the inner wall of the steel pipe 1 .

Embodiment 3

[0040] Embodiment 3: a kind of drain pipe current limiting adjustment device, such as figure 1 As shown, including the steel pipe 1, the upper and lower ends of the steel pipe 1 are welded with flange plates 2, the interior of the steel pipe 1 is provided with an annular baffle 3, the baffle 3 and the inner wall of the steel pipe 1 are perpendicular to each other, and the middle of the annular baffle 3 Form water holes. Such as Figure 6 As shown, the annular baffle plate 3 is mainly composed of four arc-shaped plates of the same size. In order to facilitate the installation of each component, the steel pipe 1 itself can be finally welded by using four arc-shaped steel plates (the number of arc-shaped steel plates is preferably the same as The number of arc-shaped plates is the same), and an arc-shaped plate is installed on each arc-shaped steel plate.

[0041] The wall of the steel pipe 1 is provided with a wire hole 102 for the steel wire 4 to pass through, such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com