Large-span main beam bidirectional rapid incremental launching equipment system and construction method

A construction method and large-span technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long cantilever length, slow pushing speed, large vertical deformation, etc., and achieve the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

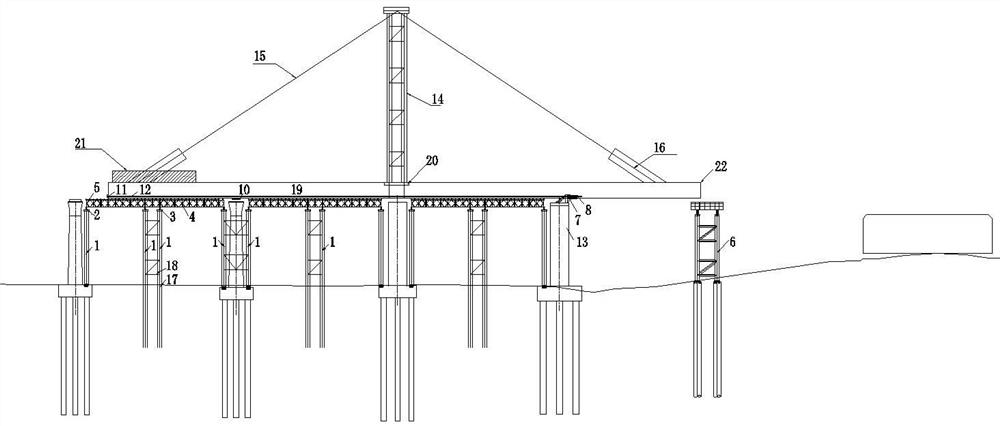

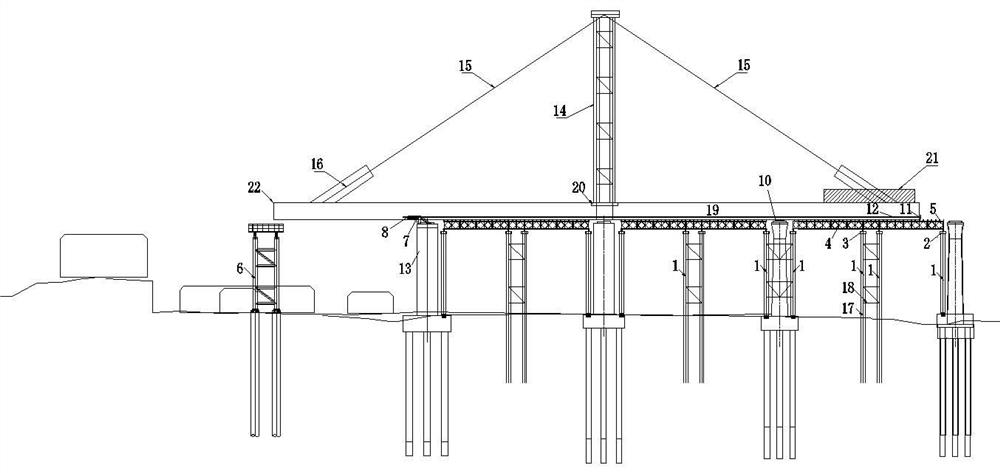

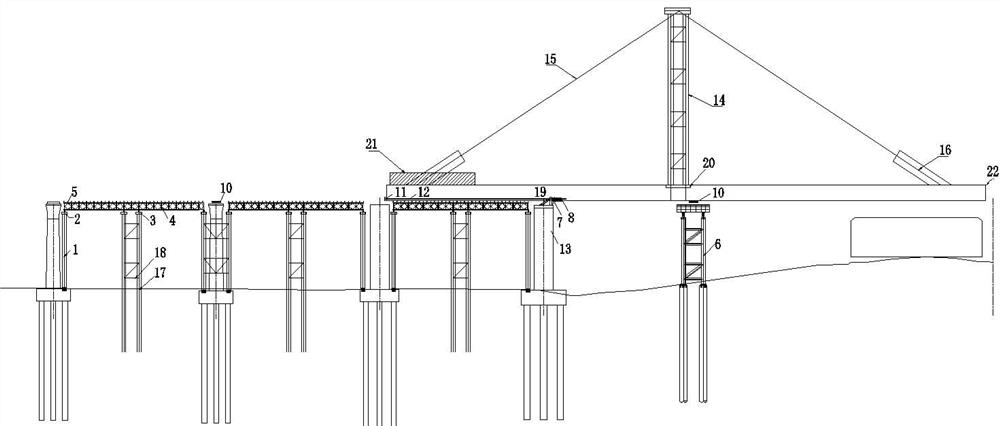

[0031] like Figure 1-4 As shown, a two-way flexible jacking equipment system for a long-span main girder includes a support system, a power system and a precise positioning system.

[0032] The support system includes column 1, unloading device 2, beam 3, longitudinal beam 4 and distribution beam 5, column 1 is set on the pier or on the foundation 17 between two pier, column 1 is provided with several rows, and the top of column 1 is installed Unloading device 2, crossbeams 3 are connected between the tops of each row of columns 1, longitudinal beams 4 are installed on several rows of crossbeams 3, distribution beams 5 are installed on the longitudinal beams 4, and main beams 19 are placed on the distribution beams 5. The model of column 1 adopts 630×12, the unloading device 2 adopts the sand box structure, the crossbeam 3 adopts double HN500×200 type steel, the longitudinal beam 4 adopts Bailey beam, the distribution beam 5 adopts I20b, the distance is 75cm, and the distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com