Integral bridge abutment structure for controlling subsidence of abutment backfill and construction method of integral bridge abutment structure

An integral abutment and console technology, applied to bridges, bridge parts, bridge construction, etc., to achieve the effects of reducing settlement, reducing lateral earth pressure, and increasing allowable value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

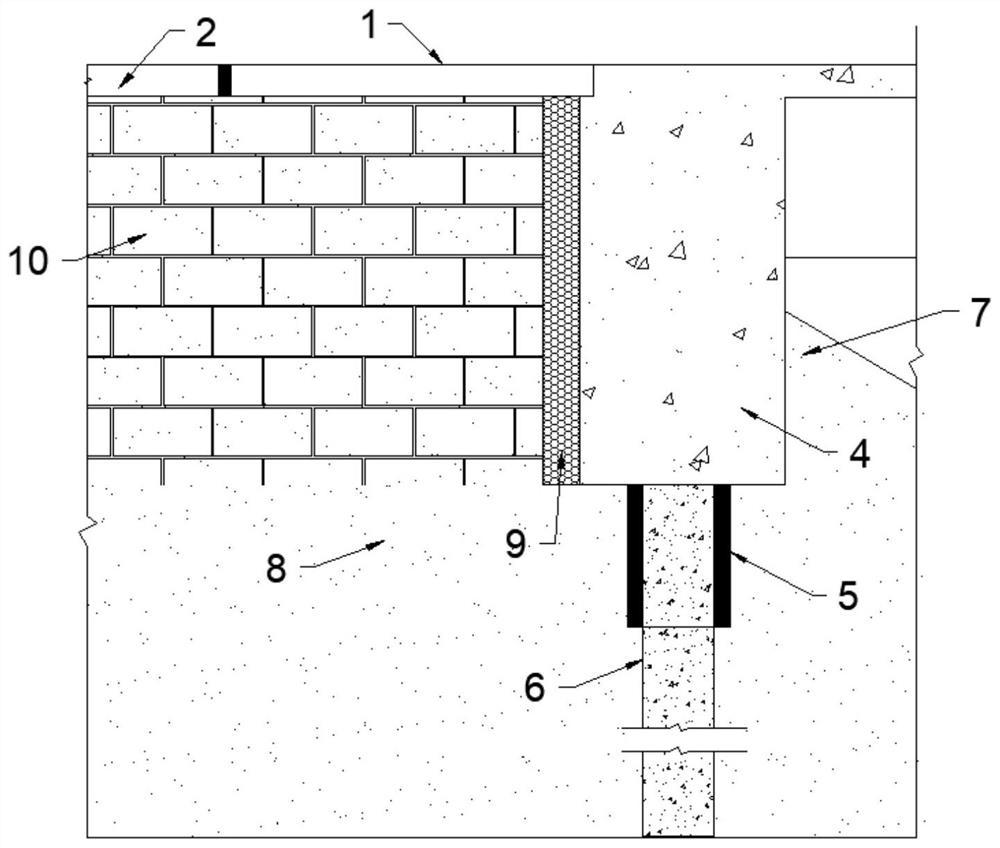

[0014] Such as figure 1 , 2 As shown, the integrated abutment structure of the console backfill settlement of the present invention includes a concrete pile foundation 6, an abutment 4, an approach plate 1 connected to the abutment 4, and a corrugated metal is fixed on the surface of the abutment 4. Plate 9 (existing product, embedded with multi-layer elastic body), between the approach plate 1 and the compacted platform backfill 8, is close to the corrugated metal plate 9 and is laid with several layers of polystyrene ( EPS) foam boards 10 (15-40 layers), each layer of foam boards 10 is laid with a filling layer of 20-30 cm thickness, and the filling height of the foam boards 10 and the filling layer is consistent with the height of the abutment 4 .

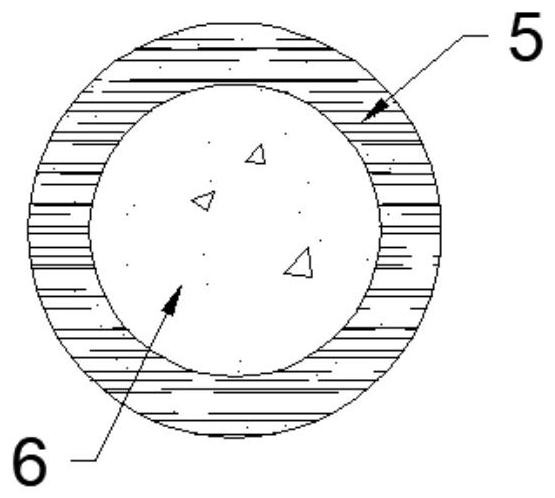

[0015] In this embodiment, the lower end of the abutment 4 is supported by a single row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com