Foundation pit supporting structure and method

A foundation pit support and foundation pit technology, which is applied in foundation structure engineering, excavation, construction, etc., can solve problems such as foundation pit instability, lack of further utilization of structure and soil interaction, and achieve the effect of structural safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

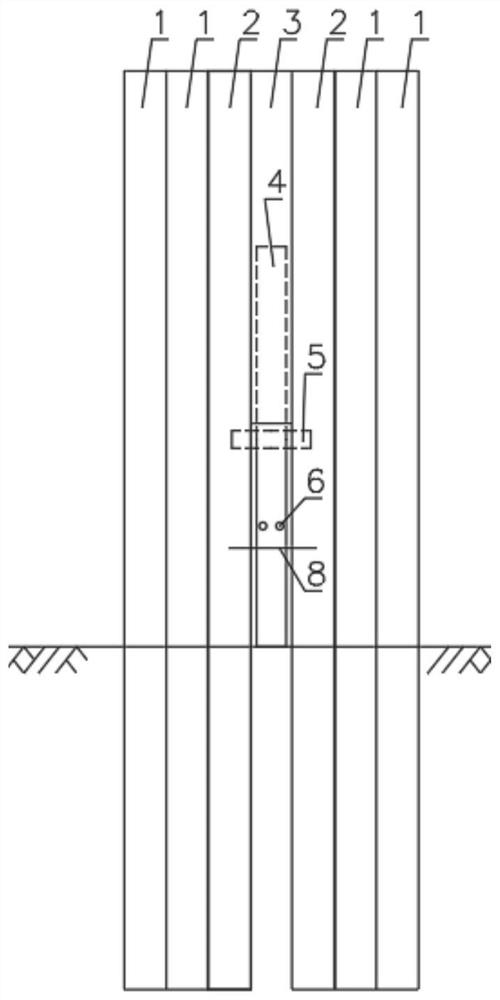

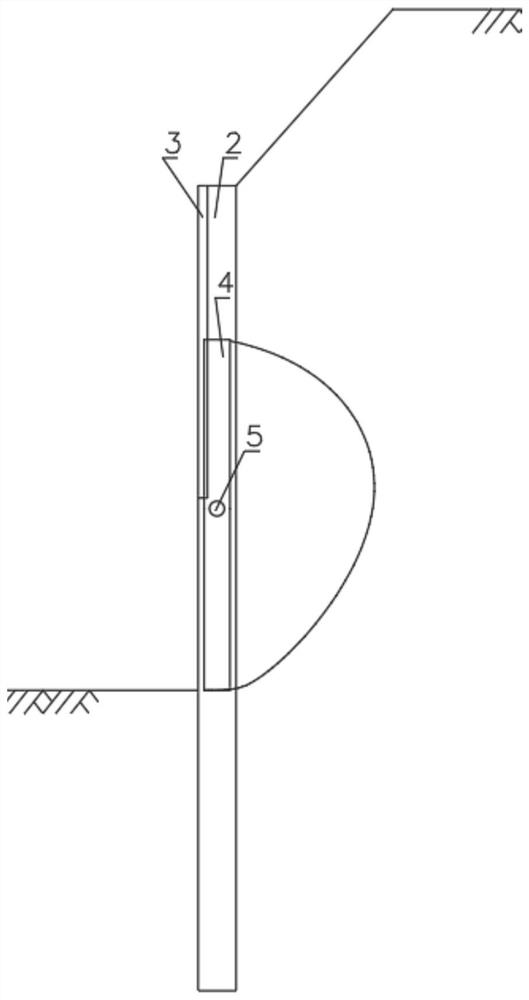

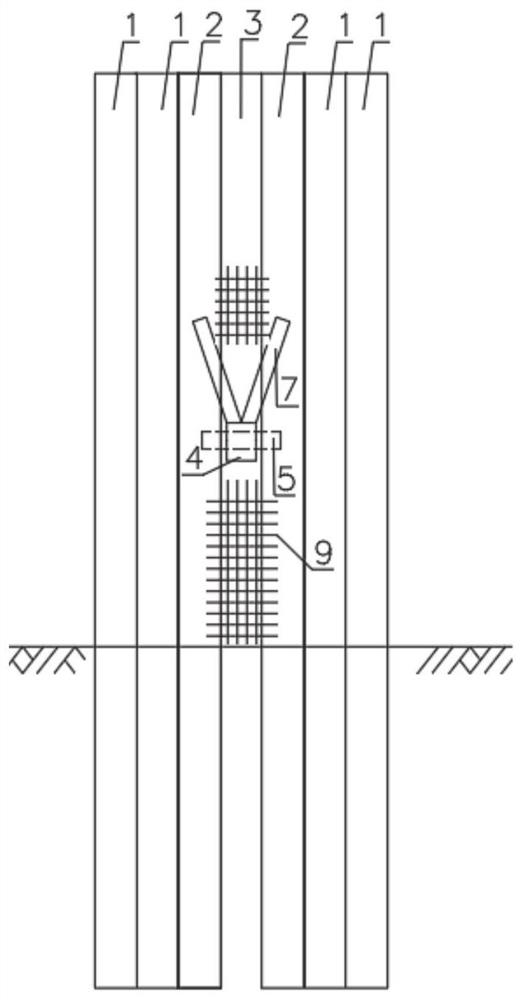

[0023] like Figure 1-Figure 6 As shown, this embodiment provides a foundation pit support structure, which includes a plurality of pile rows whose lower ends can be inserted into the soil layer below the foundation pit. The pile rows are composed of a plurality of pipe piles arranged vertically. The connecting plate 3 is fixed so that a plurality of piles are arranged in rows; a gap is formed between the lower end of the connecting plate 3 and the bottom surface of the foundation pit, and a rotating rod 4 is installed on the upper part of the gap, and one end of the rotating rod 4 can extend into the foundation pit. An unloading platform is formed in the soil layer of the side wall of the pit, and a fixed notch 6 is provided between the other end and the upper end of the pile row to fix the diagonal bracing member 7 to transmit the moment.

[0024] Specifically, in this embodiment, the two pipe piles close to the diagonal bracing member 7 need to bear the reaction force provi...

Embodiment 2

[0038] The present embodiment provides a method for foundation pit support, comprising the following steps:

[0039] Before the excavation of the foundation pit, sink the foundation pit support structure as a whole into the stratum to a set depth;

[0040] After the foundation pit is excavated to the base, make the lower end of the rotating rod 4 flush with the bottom surface of the foundation pit, and use auxiliary driving equipment to push the lower end of the rotating rod 4 to rotate towards the side wall of the foundation pit to perform rotary excavation. When rotating 90° , stop rotating;

[0041] Utilize the diagonal bracing member 7 to support between the end of the rotating rod 4 away from the side wall of the foundation pit and the upper end side of the adjacent pipe pile away from the side wall of the foundation pit;

[0042] Removal of constraints on auxiliary drive equipment.

[0043] The overall sinking depth of the foundation pit supporting structure is set as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com