Super-hydrophobic and antibacterial natural cellulose fabric and preparation method thereof

A natural cellulose and super-hydrophobic technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of poor fabric washability, high price, environmental threat, and large amount of chemicals, and achieve good stability, The effect of being convenient for industrialized production and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Set the specification to 150g / m 2 The natural cellulose cotton fabric was added to 15g / L NaOH solution at a bath ratio of 1:30 (w / v), the solution was heated to 90°C and stirred for 80 minutes, the natural cellulose cotton fabric was taken out and washed several times, and then aired dry, spare;

[0030] (2) Dissolve 4mg / mL dopamine in the buffer, control the pH value to 8.5, then add 25mmol / L CuSO 4 and 30mmol / L H 2 o 2 Composed of oxidation system, stir quickly to fully dissolve dopamine; (w / v)

[0031] (3) The alkali-treated natural cellulose cotton fabric is quickly immersed in the dopamine solution containing the oxidation system at a bath ratio of 1:50, reacted at 25°C for 50 minutes, washed and dried several times, and soaked in 1M NaOH for 20 minutes. Repeat the treatment once more in the dopamine reaction solution, take it out, wash it thoroughly, and finally dry it at 60°C for 5 hours to obtain a superhydrophobic antibacterial natural cellulose cotton ...

Embodiment 2

[0038] (1) Set the specification to 160g / m 2The natural cellulose hemp fabric is added to 25g / L NaOH solution at a bath ratio of 1:30 (w / v), the solution is heated to 80°C and stirred for 80 minutes, the natural cellulose hemp fabric is taken out and washed several times, and then aired dry, spare;

[0039] (2) Dissolve 3mg / mL dopamine in the buffer, control the pH value to 9, then add 18mmol / L CuSO 4 and 24mmol / L H 2 o 2 Composed of oxidation system, stir quickly to fully dissolve dopamine;

[0040] (3) Rapidly immerse the pretreated natural cellulose hemp fabric in a dopamine solution containing an oxidation system at a bath ratio of 1:50 (w / v), react at 30°C for 40 minutes, wash and dry it several times, and immerse it in 1M NaOH for 15 minutes , after washing, repeat the treatment once more in the above-mentioned dopamine reaction solution, take it out, wash it thoroughly, and finally dry it at 50° C. for 6 hours to obtain a superhydrophobic antibacterial natural cellu...

Embodiment 3

[0042] (1) Set the specification to 180g / m 2 The natural cellulose cotton fabric is added to 25g / L NaOH solution at a bath ratio of 1:30 (w / v), the solution is heated to 90°C and stirred for 80min, the natural cellulose cotton fabric is taken out and washed several times, and then aired dry, spare;

[0043] (2) Dissolve 6mg / mL dopamine in the buffer, control the pH value to 9, then add 30mmol / L CuSO 4 and 30mmol / L H 2 o 2 Composed of oxidation system, stir quickly to fully dissolve dopamine;

[0044] (3) Rapidly immerse the pretreated fabric in a dopamine solution containing an oxidation system at a bath ratio of 1:50, react at 45°C for 30 minutes, wash and dry it several times, and soak it in 1M NaOH for 15 minutes. Repeat the treatment once more in the solution, take it out, wash it thoroughly, and finally dry it at 60°C for 6 hours to obtain a superhydrophobic antibacterial natural cellulose cotton fabric.

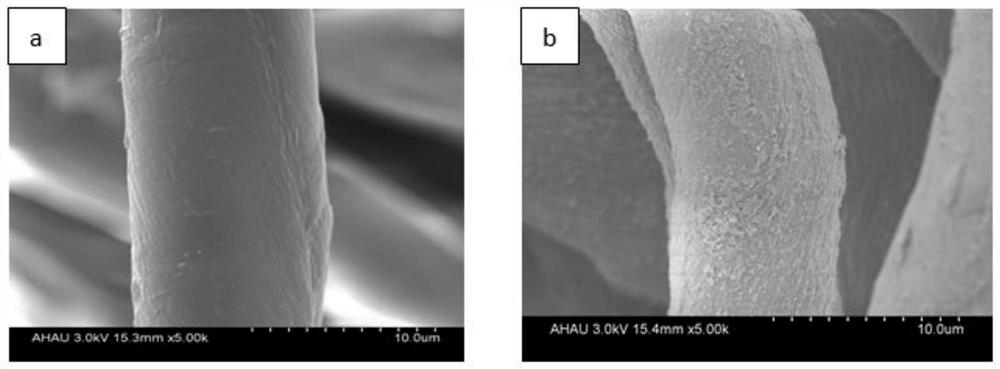

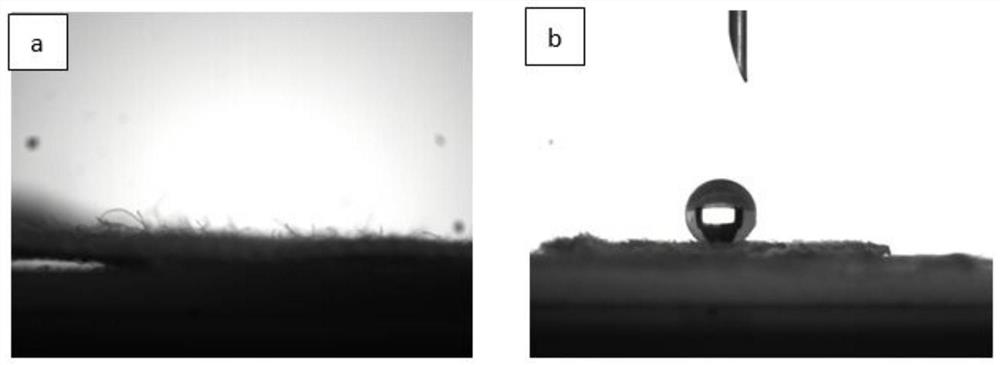

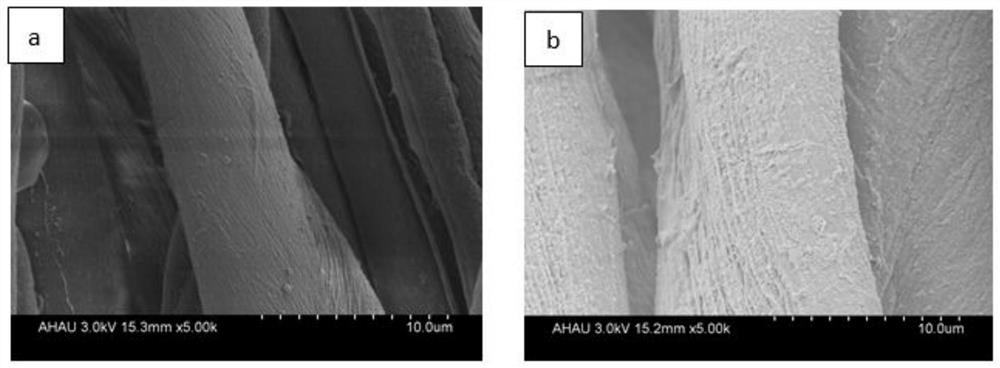

[0045] attached image 3 It is to use the method of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com