Preparation method of high-quality brown granulated sugar

A brown sugar, high-quality technology, applied in sugar production, sugar crystallization, sucrose production, etc., can solve problems such as easy agglomeration, high water content on the surface of brown sugar, which is not conducive to improving the yield of brown sugar, and reduce viscosity , Promote crystallization, and promote the effect of sucrose crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

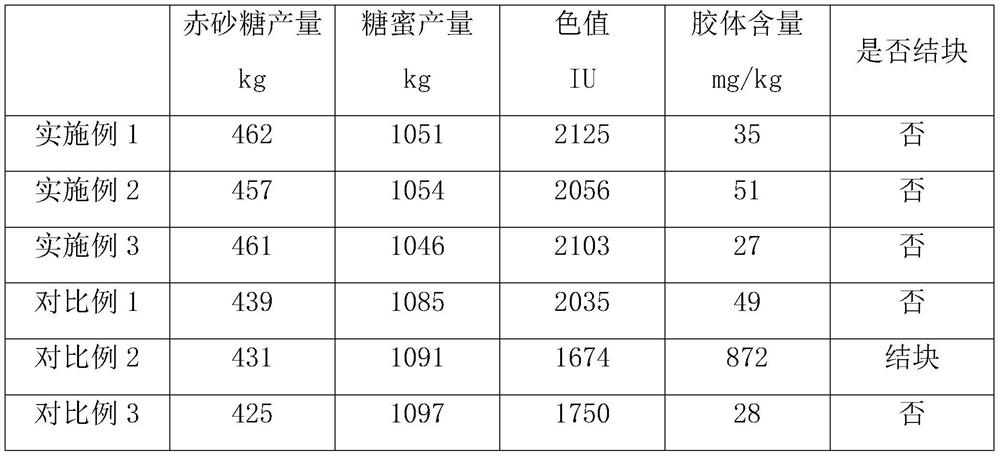

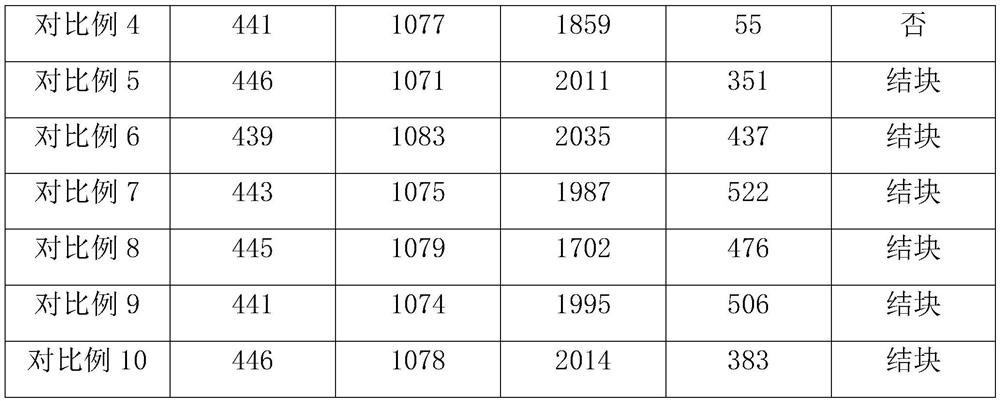

Embodiment 1

[0018] The preparation method of high-quality brown sugar includes extracting juice from raw materials, clarifying sugar juice, evaporating, boiling sugar, assisting crystallization, separating honey, and drying processes. , Add compound enzyme preparation after starting to feed raw honey, add molasses in the crystallization process of trimacete, and treat trimacete with immobilized sucrase. The compound enzyme preparation includes cellulase, xylanase, dextranase, protease, pectinase, tannase and glucose oxidase, and in every milliliter of compound enzyme preparation, the activity of cellulase is 30000IU, xylanase The activity is 4000IU, the activity of dextranase is 7500IU, the activity of protease is 4000IU, the activity of pectinase is 1500IU, the activity of tannase is 4000IU, and the activity of glucose oxidase is 1500IU. Preparation 150 grams. In the crystal-assisted crystallization process of the sugar paste, the amount of molasses added is 15% of that of the sugar syr...

Embodiment 2

[0020] The preparation method of high-quality brown sugar includes extracting juice from raw materials, clarifying sugar juice, evaporating, boiling sugar, assisting crystallization, separating honey, and drying processes. , Add compound enzyme preparation after starting to feed raw honey, add molasses in the crystallization process of trimacete, and treat trimacete with immobilized sucrase. The compound enzyme preparation comprises cellulase, xylanase, dextranase, protease, pectinase, tannase and glucose oxidase, and in every milliliter of compound enzyme preparation, the cellulase activity is 20000IU, xylanase The activity is 5000IU, the activity of dextranase is 5000IU, the activity of protease is 2000IU, the activity of pectinase is 1000IU, the activity of tannase is 5000IU, and the activity of glucose oxidase is 1000IU. Preparation 100 grams. In the crystal-assisted crystallization process of the sugar paste, the amount of molasses added is 20% of that of the sugar syrup...

Embodiment 3

[0022] The preparation method of high-quality brown sugar includes extracting juice from raw materials, clarifying sugar juice, evaporating, boiling sugar, assisting crystallization, separating honey, and drying processes. , Add compound enzyme preparation after starting to feed raw honey, add molasses in the crystallization process of trimacete, and treat trimacete with immobilized sucrase. The compound enzyme preparation includes cellulase, xylanase, dextranase, protease, pectinase, tannase and glucose oxidase, and in every milliliter of compound enzyme preparation, the activity of cellulase is 40000IU, xylanase The activity is 3000IU, the activity of dextranase is 10000IU, the activity of protease is 5000IU, the activity of pectinase is 2000IU, the activity of tannase is 3000IU, and the activity of glucose oxidase is 2000IU. Preparation 200 g. In the crystal-assisted crystallization process of the sugar syrup, the amount of molasses added is 10% of the sugar syrup, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com