Preparation method of 1,2,3-tris(2-cyanoethoxy)propane

A cyano group and propane technology, applied in the field of preparation of 1,2,3-tripropane, can solve the problems of unfavorable mass production and green environmental protection concept, large equipment investment, high energy consumption, and achieve high atomic utilization rate, The effect of small equipment investment and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

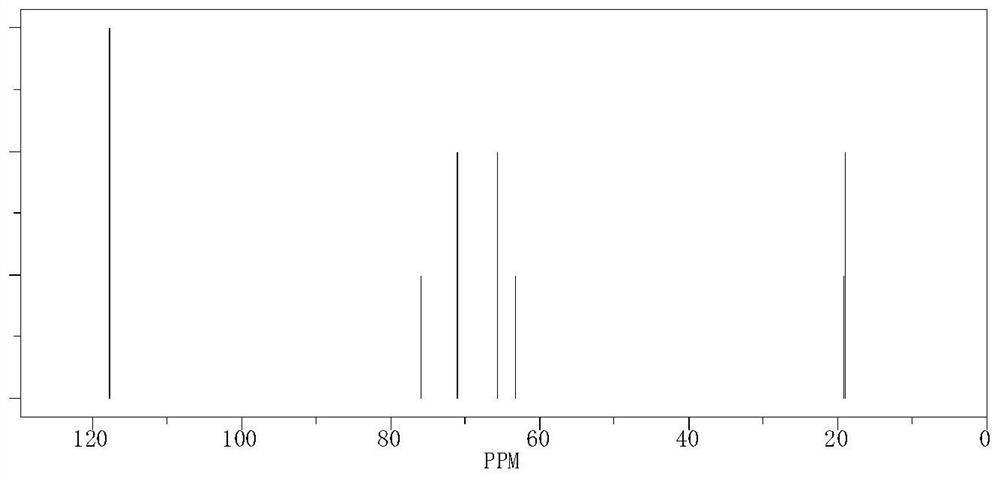

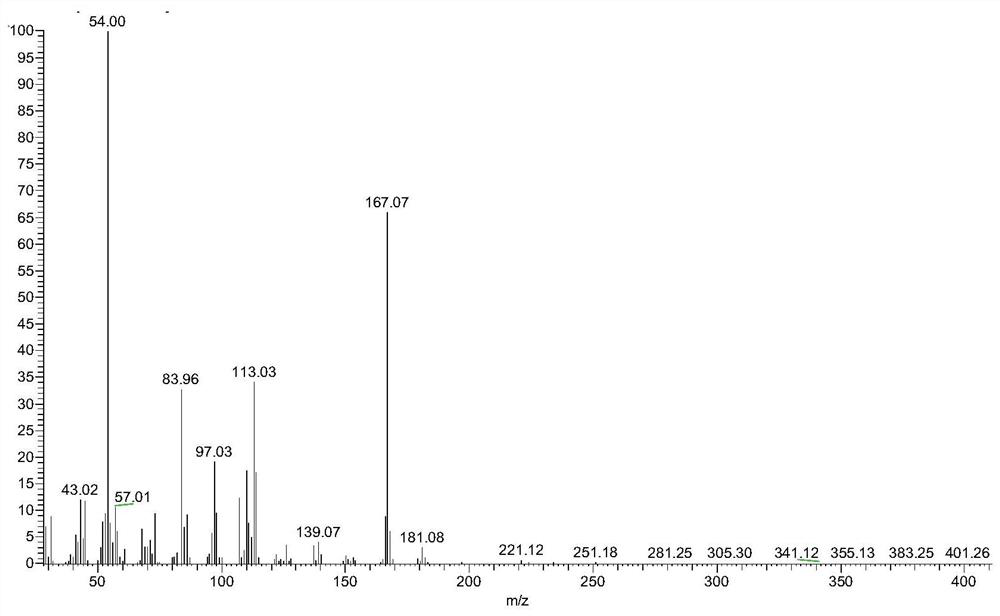

[0027] Take 9.209g of glycerol, raise the temperature to 80°C, add 0.189g of sodium methoxide, cool down to 60°C, add 13.59g of acrylonitrile dropwise, control the temperature during the dropping process to 55°C, add the time for 4 hours, and continue to cool down to 30°C , add 3.1g of acrylonitrile dropwise, control the temperature during the dropping process to 30°C, add dropwise for 0.5h, stir at 20°C for 2h, after the reaction is complete, add the system to twice the amount of water, and stir for about 20 minutes. The system was separated into layers, the aqueous phase was extracted with dichloromethane, and the organic phases were combined. Dry, filter through silica gel activated carbon, and spin dry at 40°C under -0.1 atmospheric pressure to obtain 22.63g of 1,2,3-tris(2-cyanooxy)propane (yellow liquid), with a yield of 90.04%. Determined by gas chromatography, the purity of the resulting product is 99.06%, as Figure 1-3 , using mass spectrometry, H spectrum and C spe...

Embodiment 2

[0030] Take 9.209g of glycerol, raise the temperature to 70°C, add 0.216g of sodium methoxide, cool down to 65°C, add 13.876g of acrylonitrile dropwise, control the temperature during the dropping process to 50°C, drop the time for 5h, and continue to cool down to 35°C , add 3.084g of acrylonitrile dropwise, control the temperature during the dropping process to 15°C, add dropwise for 1h, stir at 15°C for 3h, after the reaction is complete, add the system to twice the amount of water, and stir for about 20 minutes. The system was separated into layers, the aqueous phase was extracted with dichloromethane, and the organic phases were combined. Dry, filter through silica gel activated carbon, and spin dry at 60°C under -0.1 atmospheric pressure to obtain 22.64g of 1,2,3-tris(2-cyanooxy)propane (yellow liquid), with a yield of 90.10%. As determined by gas chromatography, the purity of the obtained product is 99.03%, and the obtained product is identified as 1,2,3-tris(2-cyanooxy)...

Embodiment 3

[0032] Take 9.209g of glycerol, raise the temperature to 90°C, add 0.21g of sodium methoxide, cool down to 55°C, add 13.33g of acrylonitrile dropwise, control the temperature during the dropping process to 60°C, drop the time for 3 hours, and continue to cool down to 25°C , add 3.1g of acrylonitrile dropwise, control the temperature during the dropping process to 20°C, add dropwise for 40min, stir at 30°C for 2.5h, after the reaction is complete, add the system to twice the amount of water, and stir for about 20 minutes. The system was separated into layers, the aqueous phase was extracted with dichloromethane, and the organic phases were combined. Dry, filter through silica gel activated carbon, and spin dry at 50°C under -0.1 atmospheric pressure to obtain 22.75g of 1,2,3-tris(2-cyanooxy)propane (yellow liquid), with a yield of 90.54%. As determined by gas chromatography, the purity of the obtained product is 99.28%, and the obtained product is identified as 1,2,3-tris(2-cya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com