Intelligent logistics conveyer equipment

A technology of transmission equipment and intelligent logistics, which is applied in the direction of conveyors, transportation and packaging, etc., and can solve problems such as extrusion downward, cargo position deviation, transmission belt vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

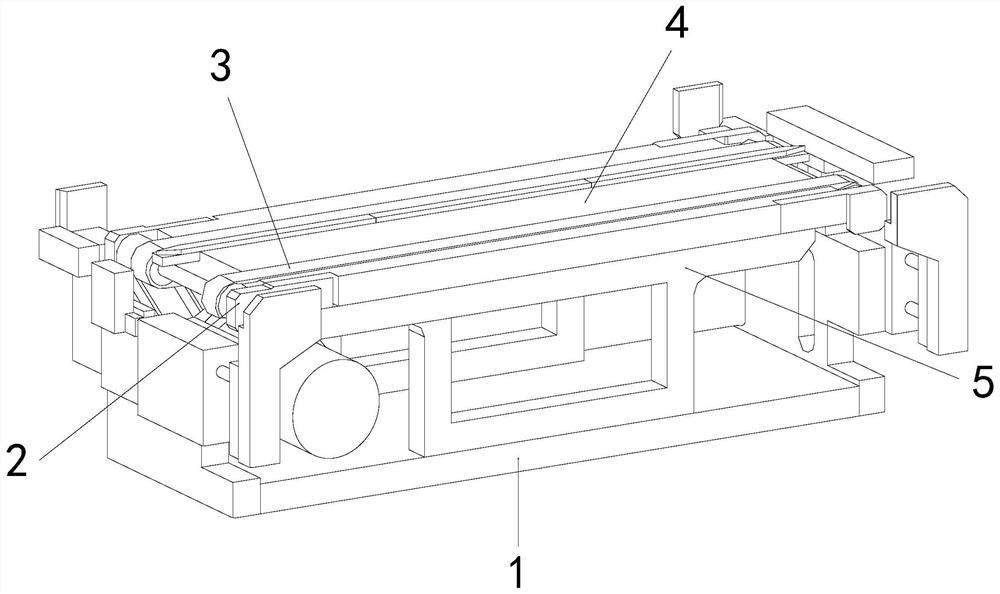

[0025] as attached figure 1 To attach Figure 4 As shown, the present invention provides an intelligent logistics transmission device, the structure of which includes a base 1, a tension mechanism 2, a transmission belt 3, a bearing platform 4, and a support seat 5, and the two ends of the tension mechanism 2 are nested and engaged with the bearing platform 4. Between the right side, the inner wall of the transmission belt 3 is tensioned and fixed to the outer wall of the tensioning mechanism 2, the lower end of the bearing table 4 is fixed to the upper end of the support seat 5 by screws, and the lower end of the support seat 5 is welded and fixed to the upper end of the base 1;

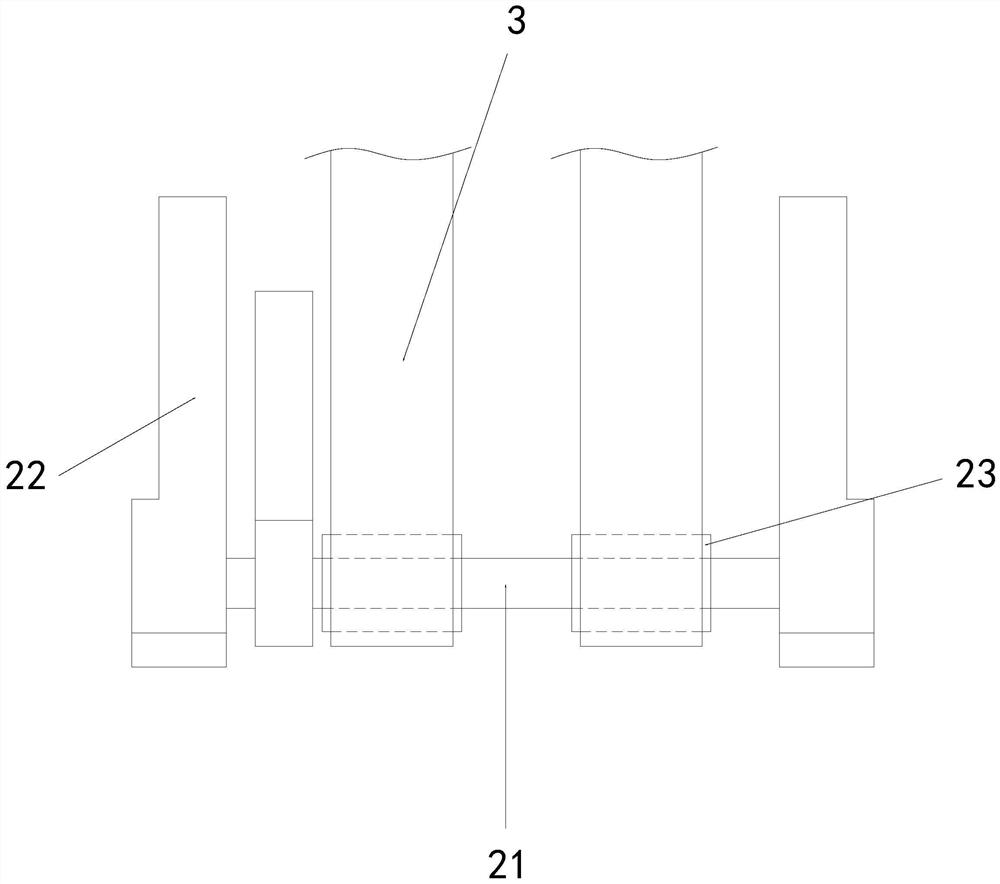

[0026] The tensioning mechanism 2 is composed of a rotating shaft 21, an embedding plate 22, and a matching mechanism 23. The outer wall of the rotating shaft 21 is fixed to the inner wall of the matching mechanism 23 with interference, and the outer walls of both ends of the embedding plate 22 are ...

Embodiment 2

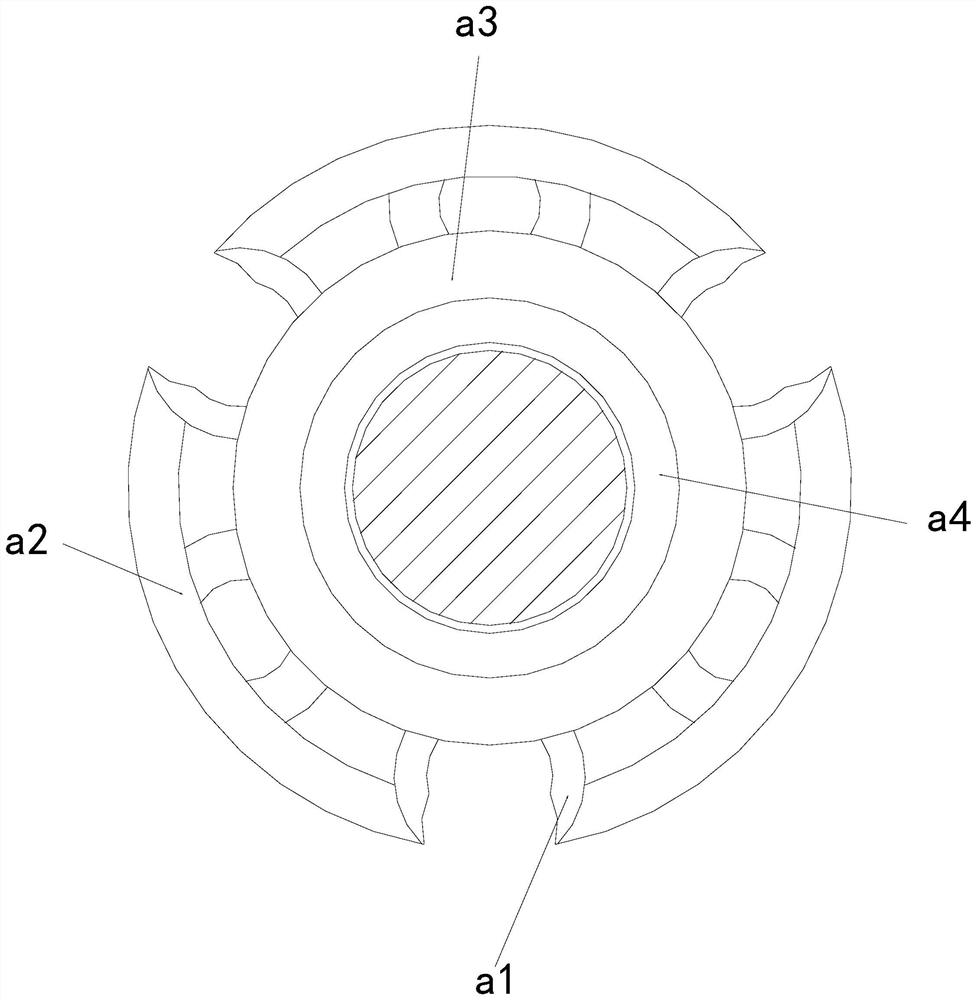

[0031] as attached Figure 5 to attach Figure 7 As shown: the opener b1 is composed of a power body c1, a connecting rod c2, and an embedded buckle c3. The inner wall of the power body c1 is nested and fitted between the connecting rods c2, and the two ends of the connecting rod c2 are welded and fixed Between the embedded buckles c3, the inner wall of the embedded buckle c3 is nested and engaged with the outer wall of the clamping rod b3. There are two connecting rods c2 in total. After they are combined, their structure is a U-shaped structure. The settlement of the middle section There is more space when the connecting rod c2 moves.

[0032] Wherein, the power main body c1 is composed of a retarder d1, a closing leaf d2, an alignment plate d3, a spring d4, and a housing d5. One end of the leaf d2 is fastened to both ends of the inner wall below the housing d5 through a latch, the outer wall of the alignment plate d3 is gap-fitted on the inner wall of the housing d5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com