Drilling equipment for portable heat insulation plate

A drilling equipment and plate technology, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems of convenient insulation board position offset, drilling offset, flapping and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

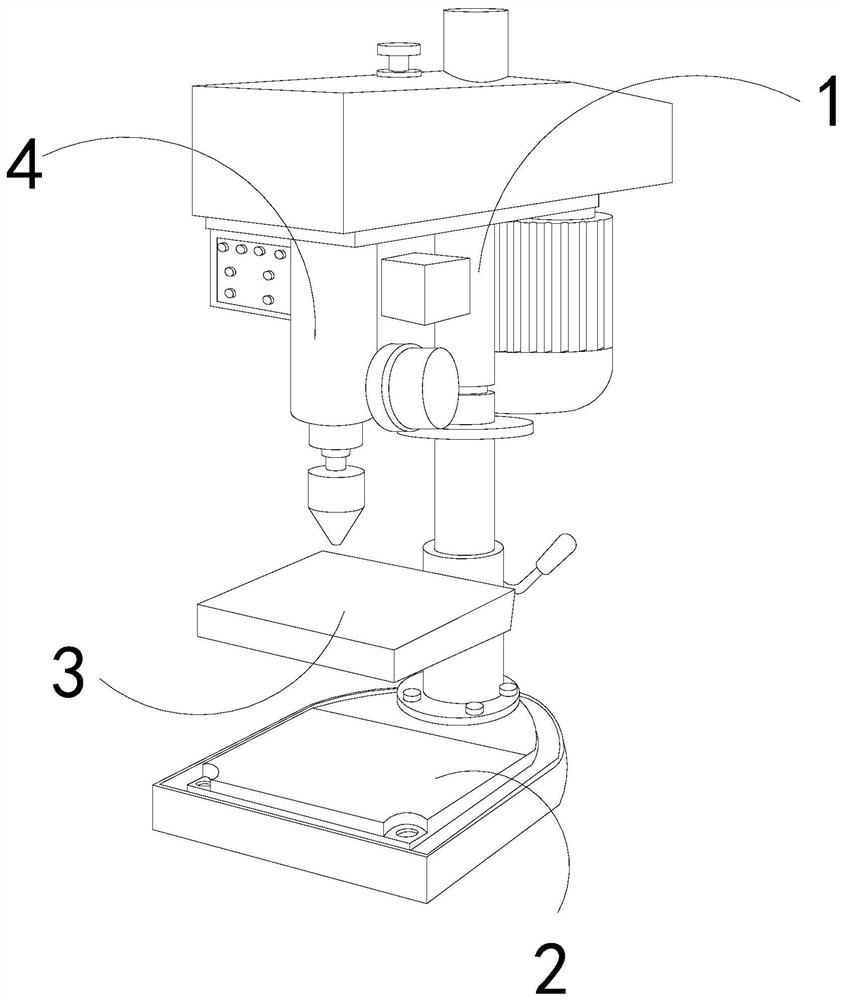

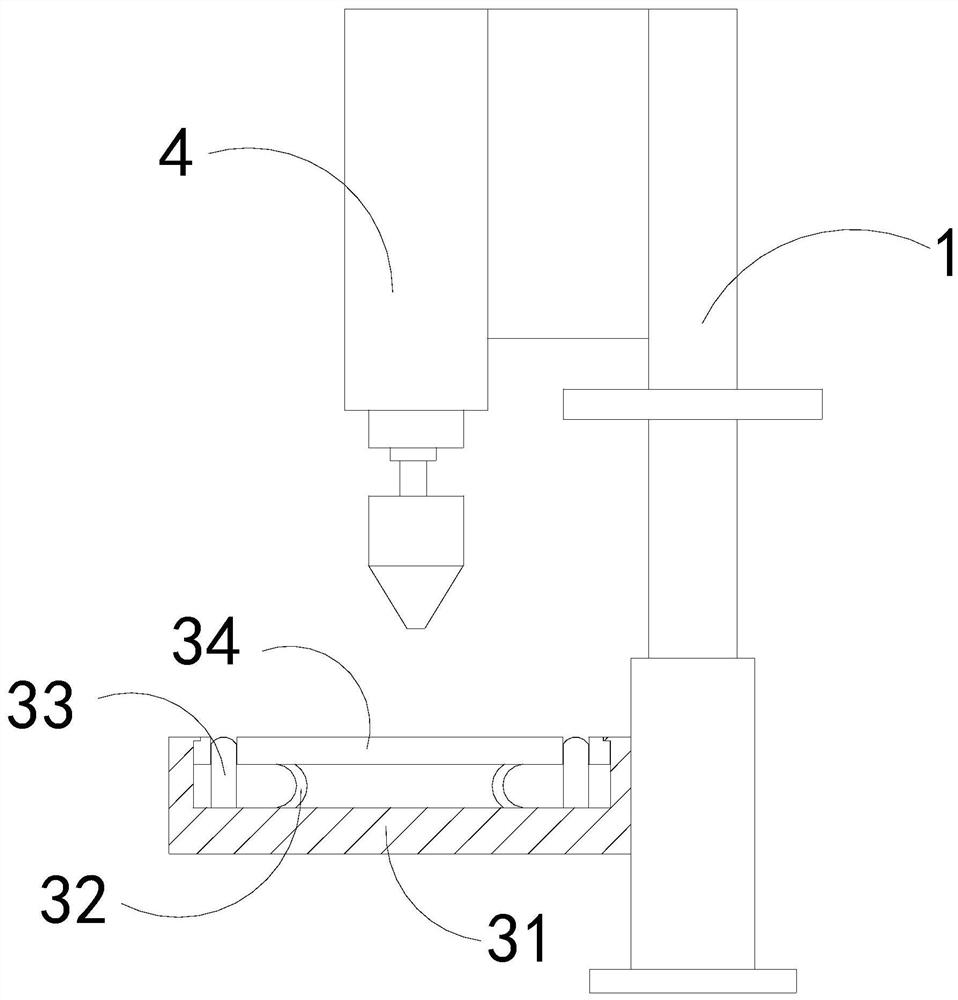

[0027] The invention provides a drilling device for portable heat-insulating boards, the structure of which includes a support rod 1, a base 2, an operating table 3, and a drill bit 4, the support rod 1 is embedded in the upper end of the base 2, and the drill bit 4 is installed At the front end of the support rod 1, the operating table 3 is welded to the supporting rod 1; the operating table 3 includes a bottom plate 31, an elastic sheet 32, an outstretched rod 33, and a force plate 34, and the elastic sheet 32 is installed on Between the bottom of the force plate 34 and the base plate 31, the bottom of the outrigger 33 is embedded and connected with the bottom of the inner wall of the base plate 31, and the outrigger 33 is in clearance fit with the force plate 34, and the force plate 34 It is movably engaged with the base plate 31 .

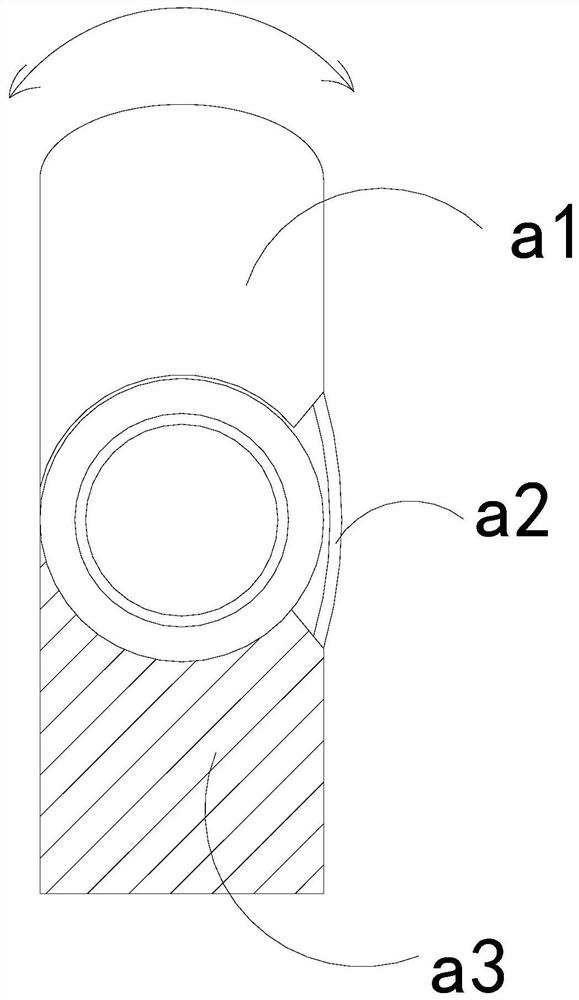

[0028] Wherein, the outrigger 33 includes a single pendulum plate a1, a reset pie...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the force bearing plate 34 includes a suction plate c1, an upper touch plate c2, a sealing block c3, and a bottom frame c4. The bottom frame c4 is movable, and the sealing block c3 is installed at the bottom of the inner wall of the bottom frame c4. There are four adsorption plates c1, which are evenly distributed in parallel on the upper touch plate c2. The extrusion of the plate against the upper contact plate c2 can make the upper contact plate c2 shrink downward along the bottom frame c4, so that the sealing block c3 can seal the middle part of the suction disk c1, so that the suction disk c1 can be adsorbed on The bottom of the Portable Heat Shield.

[0036] Wherein, the suction plate c1 includes an upper connection plate c11, a deformation block c12, a booster bar c13, and a receiving plate c14. The deformation block c12 is installed between the upper connection plate c11 and the receiving plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com