An indoor wood ornament preprocessing device

A technology for pre-processing and wood ornaments, applied in the field of indoor wood ornament pre-processing devices, can solve the problems of reduced protection effect, damage to wood veneer, bumping, etc., to achieve the effect of improving protection effect and preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

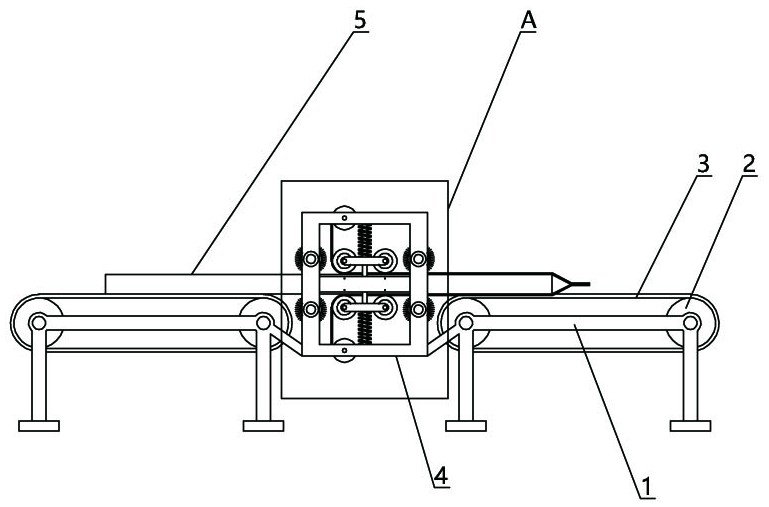

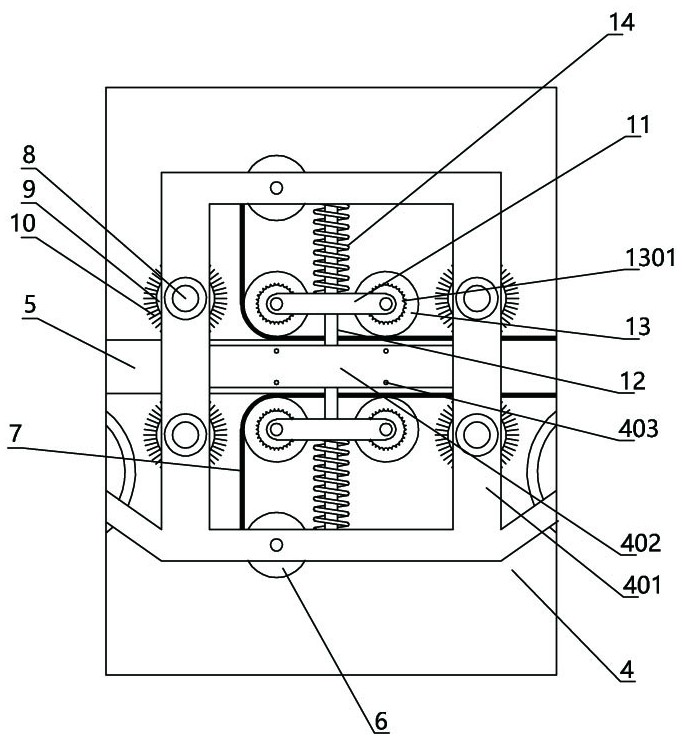

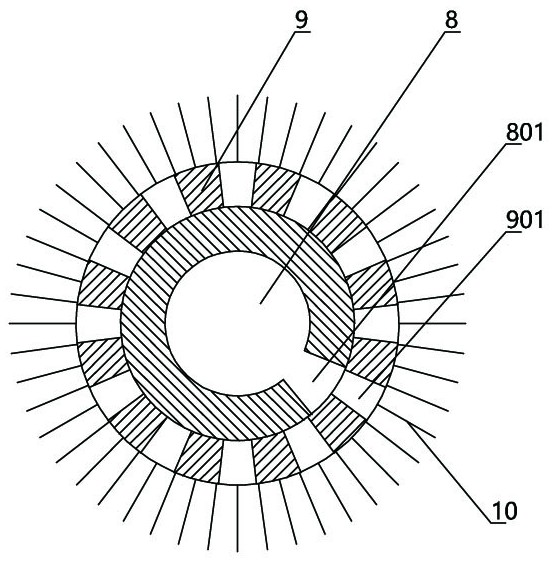

[0014] like Figure 1-3 As shown, a pre-processing device for indoor wood ornaments includes two sets of bases 1 symmetrically distributed from left to right, and each set of bases 1 are symmetrical in the front and rear. The two transmission wheels 2 are arranged on two transmission wheels 2. The front and rear ends of the two transmission wheels 2 are rotatably connected with the corresponding side base 1 through rolling bearings. There is a set of fixed frames 4 which are symmetrical in the front and rear, and the fixed frame 4 is composed of an edge frame 401 and a cross bar 402 fixed in the middle of the edge frame 401. Both the front and rear ends of the wheel 6 are rotatably connected to the edge frame 401 through rolling bearings, a protective film 7 is wound on the unwinding wheel 6, and two air extraction pipes 8 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com