Automatic carrying robot for unit support

A handling robot and automatic technology, applied in the direction of manipulators, conveyor objects, transportation and packaging, etc., can solve problems such as poor road conditions, large safety risks, and affecting the safety of manual operations, and achieve the effect of compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

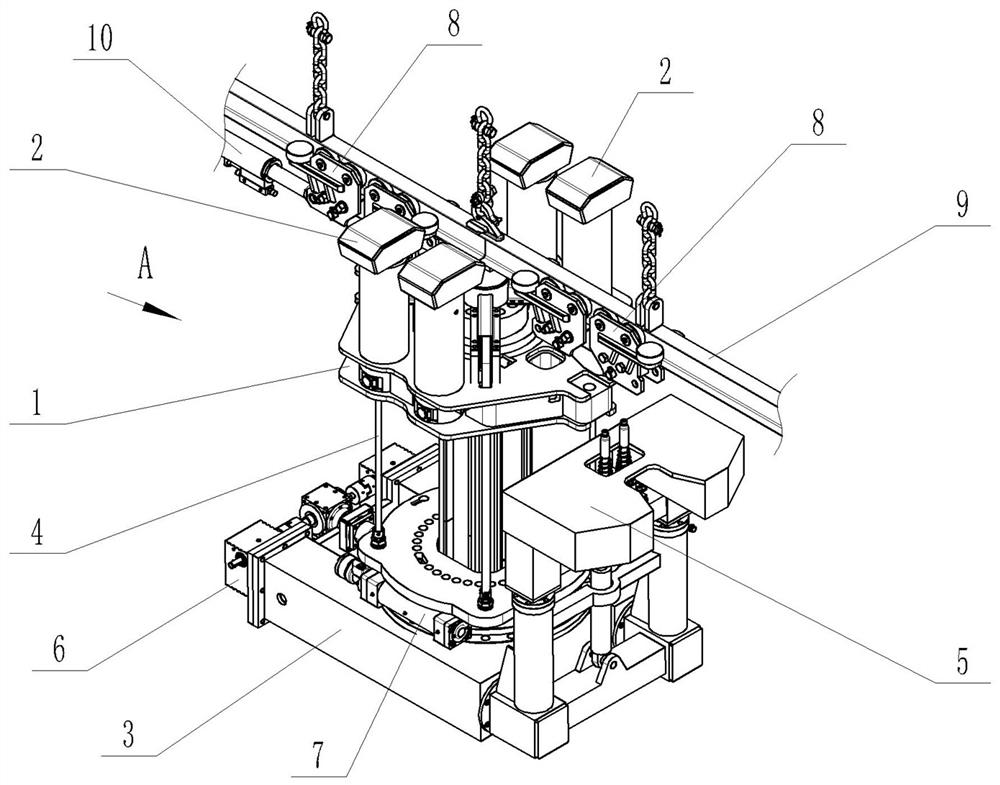

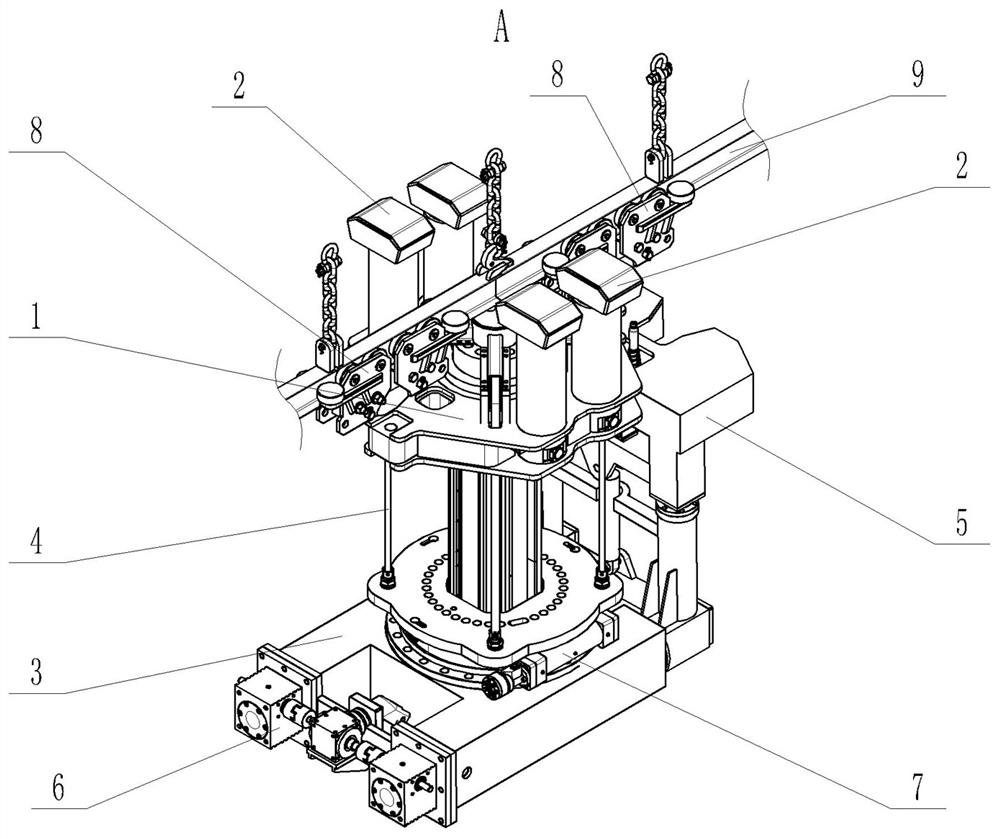

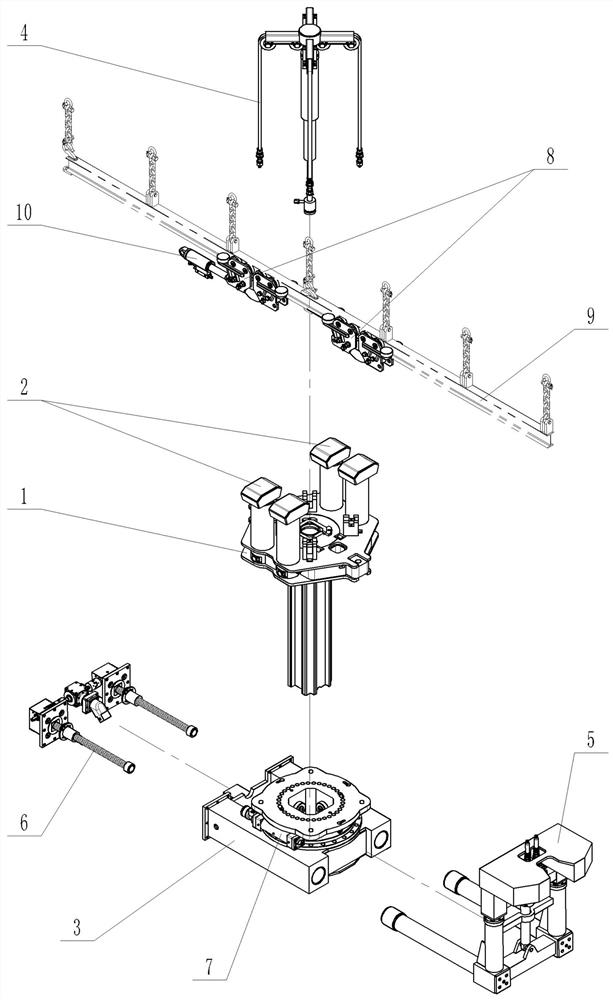

[0038] according to Figure 1-20 The specific structure of the present invention will be described in detail. The unit bracket automatic handling robot includes a carrier body 1, the carrier body 1 is composed of a horizontally arranged carrier platform 11, and the front and rear ends of the carrier platform 11 are respectively slidably connected to the walking track 9 arranged on the roof of the roadway through a pulley assembly 8 , and the pulley assembly 8 is also provided with a positioning hydraulic cylinder 10 for precise positioning. The upper part of the carrying platform 11, located at the positions on both sides of the walking track 9, is provided with supporting mechanisms 2 respectively;

[0039] The bearing platform 11 of the bearing body 1 is composed of a bearing platform main body 19, and the left and right sides of the bearing platform main body 19 are respectively provided with a connecting sleeve installation part 20, and the connecting sleeve installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com