A fixture for the production of industrial adhesive products

A fixing device, industrial adhesive technology, applied in workpiece clamping devices, manufacturing tools, material gluing, etc., can solve the problems of offset printing and indentation of industrial adhesive products, inability to fix materials, and easy falling of materials, etc., to improve efficiency. , The fixing method is reliable and firm, and the transmission is stable and continuous.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

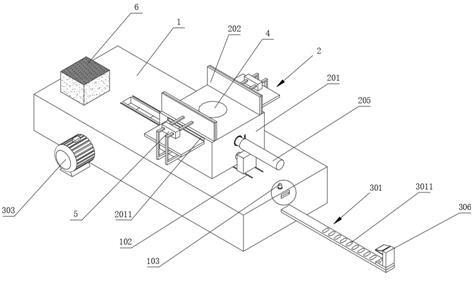

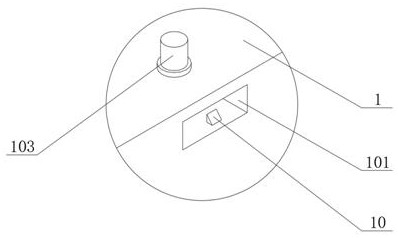

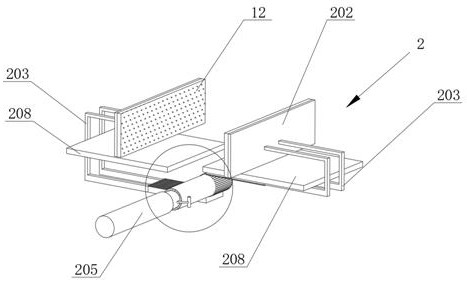

[0039] see Figures 1 to 7 , a fixing device for the production of industrial adhesive products, including a base 1, a fixing mechanism 2 that clamps the industrial adhesive products at the top of the base 1, a transmission mechanism 3 that drives the fixing mechanism 2 to move in a direction inside the base 1, and the fixing The mechanism 2 is slidingly connected to the upper surface of the base 1, and the transmission mechanism 3 is fixedly connected to the lower end of the fixing mechanism 2; The vertical splints 202 parallel to each other on both sides of the upper end of the 201, the transmission rod 203 that drives the vertical splint 202 to move horizontally, the upper end of the fixed platform 201 is provided with an electronic scale 4, and the middle section of the transmission rod 203 is provided with a pressure sensor 5, so The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com