Arc Additive Device and Method Using Vibration Aging to Control Stress and Deformation

A vibration aging and control device technology, which is applied in the field of additive manufacturing, can solve the problems of large deformation of formed parts and concentrated stress distribution, and achieve the effects of stress uniformity, stress reduction and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

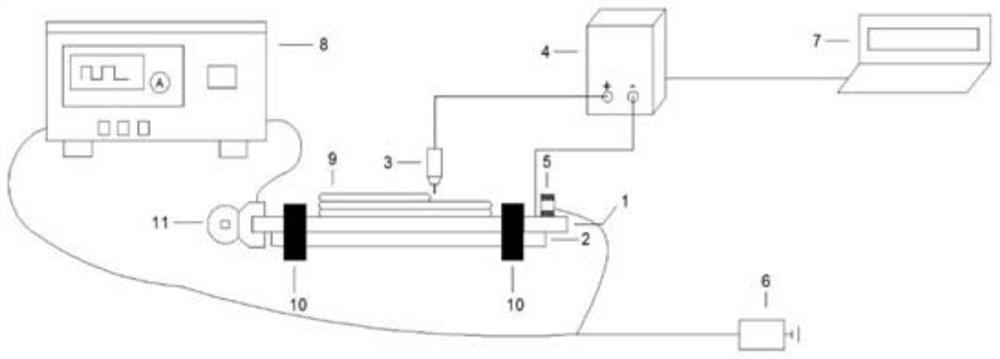

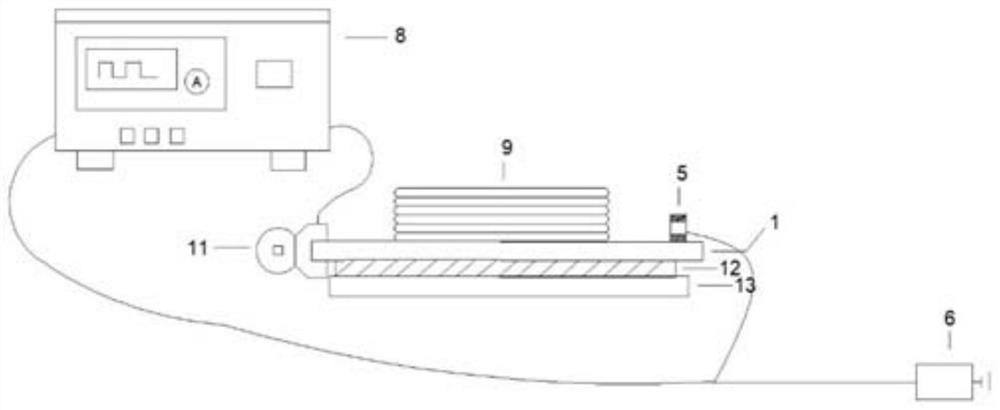

[0049]Example: Use vibration aging to control stress deformation in low carbon steel arc additive manufacturing

[0050] The substrate is grinded and cleaned with oil.

[0051] Installing and debugging the device, securing the substrate through the electromagnetic clamp to the upper surface of the base. The activation excitation is applied to the substrate, and the vibration force of the vibration is 5 kN, the frequency is 50 Hz by the vibration timing control device. The welding gun arcs above the substrate. The type of solder torch is MAG, the arc current of the welding gun is 180A, the arc voltage is 20V, the electricity; the wire diameter is The protective gas of the solder torch is argon and carbon dioxide mixed gas, and the gas flow is 20 l / min, and the frequency and increase in the vibration in real time through the vibration sensor during the manufacturing process. After the addition of a layer is deposited, turn off the electromagnetic clamp, adjusting the vibration fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com