A processing device for a bearing outer ring

A processing device and a technology for bearing outer rings, applied in the field of bearing processing, can solve problems such as the inability to process steel rings with different diameters, and achieve the effect of convenient recovery and discharge, and efficient clamping position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

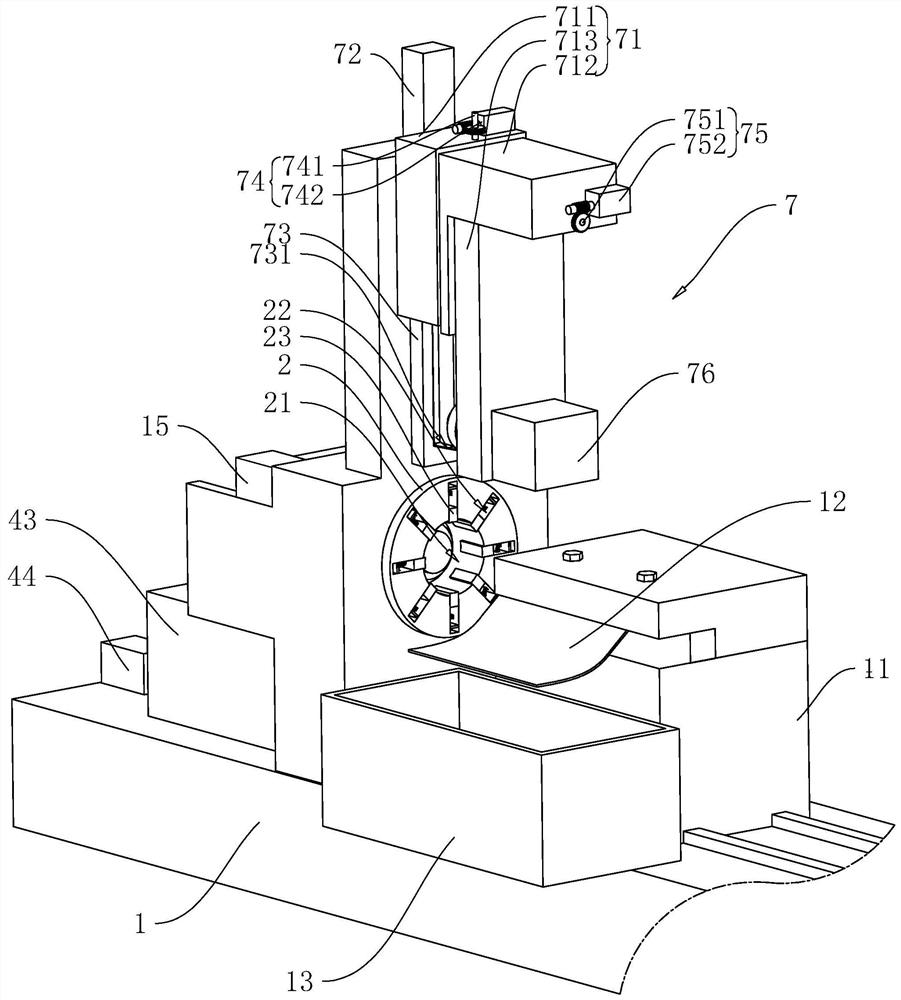

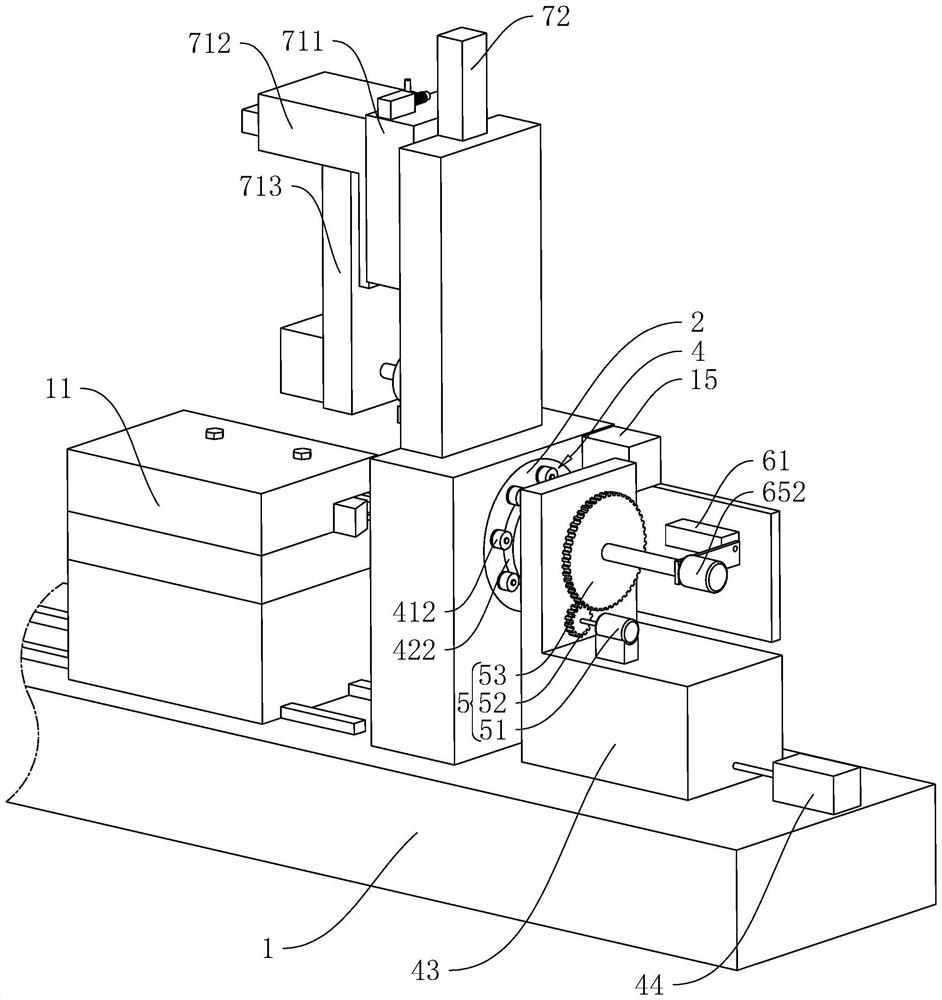

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses a processing device for bearing outer rings, referring to figure 1 , including a frame 1, the frame 1 is horizontally rotatably installed with a cylindrical base 2, and the axis of the base 2 is perpendicular to the transport direction in which the steel ring is transported to the frame 1. The frame 1 is provided with a first driving part, the first driving part includes a first motor 15, and the first motor 15 is connected to the base 2 through a gear transmission.

[0041] refer to figure 1 and figure 2 A mounting hole 21 is opened coaxially through the base 2, and one end of the base 2 protrudes from the frame 1 for more convenient loading. The inner wall of the installation hole 21 is provided with a plurality of fixing holes 22 with a square cross-section at intervals in the circumferential direction, and a fixing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com