Cottonmeal processing system and technology

A processing system and cottonseed meal technology, applied in food processing, food science, feed, etc., can solve the problems of liver and male reproductive system damage, limit the wide application of protein resources, reduce the absorption efficiency of cottonseed protein, etc., and achieve the reduction of cottonseed meal toxicity , The process is simple and practical, and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

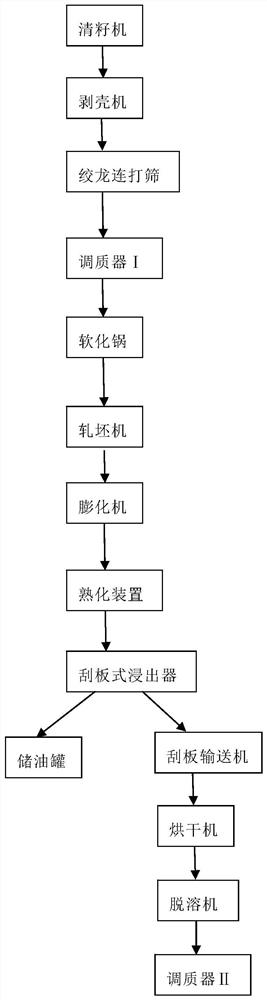

Embodiment 1

[0031] A cotton meal processing system, including a seed cleaning machine, a sheller, an auger continuous beating screen, a 5-layer vertical conditioner I, a horizontal softening pot, a hydraulic double-roll flaking machine, an extruder, a curing device, and a scraper Plate extractor, oil storage tank, dryer, desolventizer and 5-layer vertical conditioner II; the extruder adopts fixed template, twin-screw, and the membrane hole diameter is Φ6mm;

[0032] After being cleaned by the seed cleaning machine, the cottonseed enters the entrance of the sheller for shelling, and then the shells and kernels enter the entrance of the auger for continuous beating and screening. After separation, the cottonseeds enter the entrance of the 5-layer vertical conditioner I for conditioning, and then enter the The softening treatment at the entrance of the horizontal softening pot, after softening, it enters the entrance of the hydraulic double-roll rolling machine for rolling, and the rolled fla...

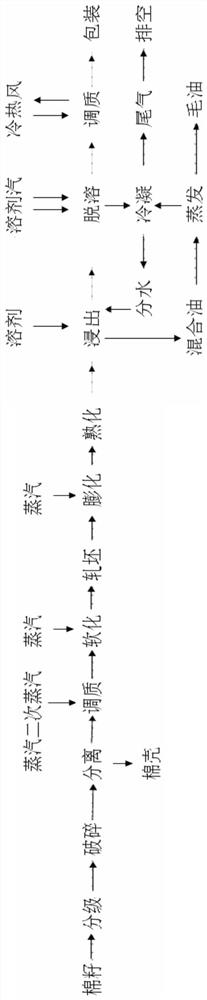

Embodiment 2

[0034] The invention provides a process and equipment scheme that can reduce the content of gossypol as follows.

[0035] According to the 300-ton cottonseed processing line in Xinjiang, the processed materials enter the 5-layer vertical conditioner for multi-layer conditioning (heating, adding water) treatment, and the temperature is 80°C and the moisture content is 16 %, the time is 10 minutes, which is conducive to the conversion of gossypol into bound gossypol as soon as possible, and the phospholipid absorbs water and combines with gossypol as soon as possible to reduce protein loss. Heating and precipitation, the softened material temperature is 95°C, water content is 9%, softening time is 20 minutes, the thickness of the billet is 0.25mm, and the qualified flakes enter the extruder evenly and stably, the extruding temperature is 115°C, the water content is 8%, and the pressure is 40Mpa. The puffing machine adopts a fixed template, the die hole is Φ6mm, and the flakes ar...

Embodiment 3

[0038] The present invention also provides a process and equipment scheme for increasing the water-soluble nitrogen content of cottonseed meal. The water-soluble protein is denatured by heat, so the processing conditions are selected to be less exposed to high temperature, and the high temperature condition is short-lived. The specific processing conditions are as follows:

[0039]According to a cottonseed processing line with a daily processing capacity of 300 tons, the strength of peeling should be increased as much as possible when peeling. The material enters the conditioner and is tempered for 10 minutes at a low temperature of 80°C. After conditioning, the material enters the softening pot and raises the temperature to 100°C, reduce the moisture content of the material by 9%, softening time for 10 minutes, adjust the plasticity and toughness of the material to facilitate rolling, the thickness is 0.25mm, the adjusted material enters the extruder, short-term high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com