Method for operating an injection-molding machine, in particular with respect to improved constant mold filling, and injection-molding machine for carrying out the method

An injection moulding machine, a technique for injection moulding, applied in the field of injection moulding machines for operating injection moulding machines and for implementing the same, in particular with regard to improving constant mould filling, capable of solving problems such as the inability to compensate for viscosity changes disturbing variables etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

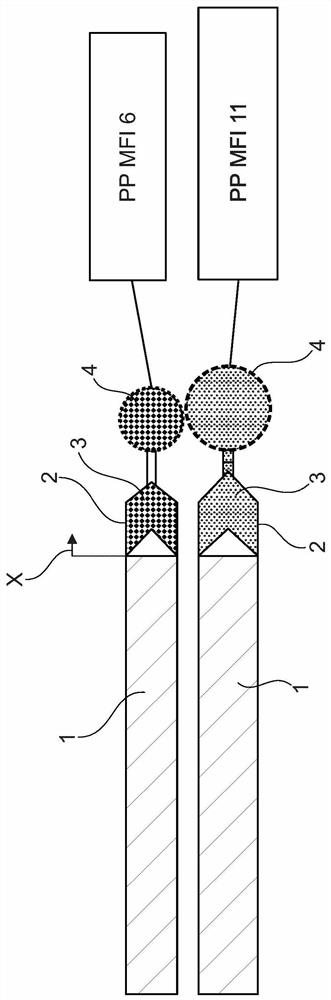

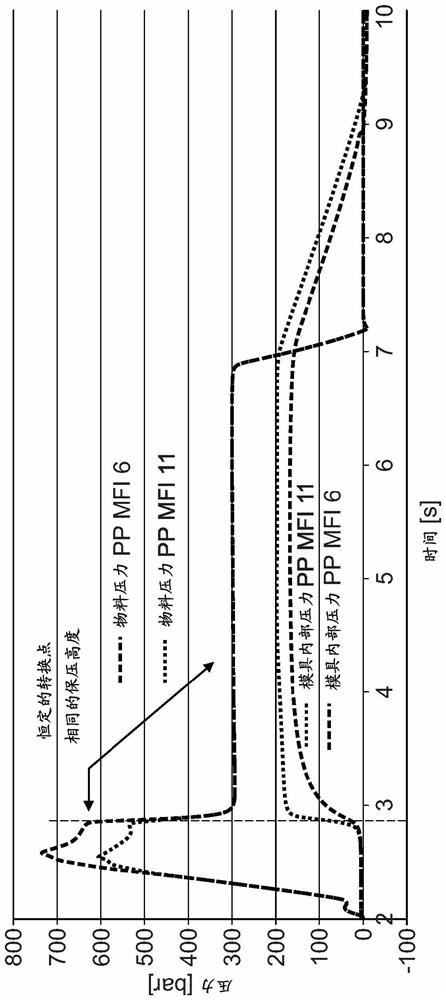

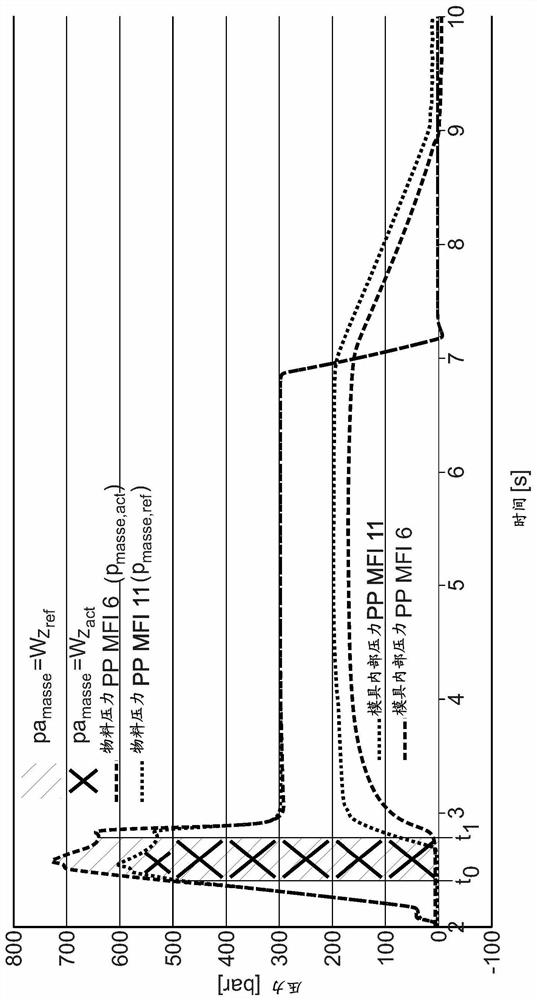

[0157] Now, next, with the help of figure 1 and figure 2 To illustrate the basic relationship between cavity pressure, viscosity and filling volume during injection molding.

[0158] exist figure 1 A worm 1 in a worm cylinder 2 of a plastic injection molding machine (not shown) is strongly schematically shown in FIG. exist figure 1 In the upper illustration of , a polypropylene material (PP material) with a melt flow index (melt flow index, MFI) of 6 is provided in the worm antechamber 3 and, schematically, in the cavity 4 . This is a relatively high viscosity (viscous) material in the melt state. exist figure 1 In the example shown below, polypropylene is also present in the worm antechamber 3 and cavity 4, but this polypropylene is less viscous (thin) in the melt and has a melt flow index value of 11 MFI. It is clear that, in the same worm position X, cavity 4 contains more melt volume (fill volume) in the case of polypropylene with MFI=11. In the case of high-vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com