Rapid heat dissipation shell for outdoor laser

A heat dissipation shell and laser technology, applied in the field of lasers, can solve problems such as difficulty in keeping the shell clean, lack of automatic cleaning, and reduced shell efficiency, so as to achieve the effects of improving heat dissipation, cleaning effect, and heat dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

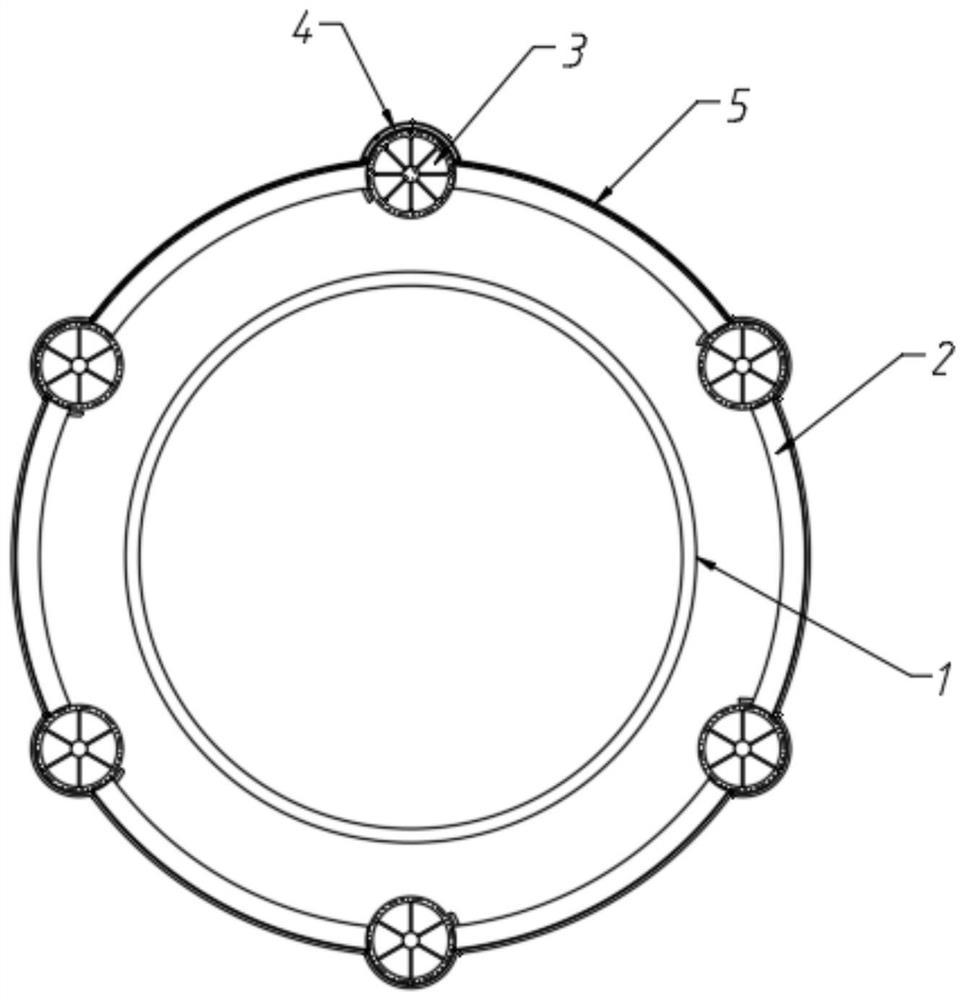

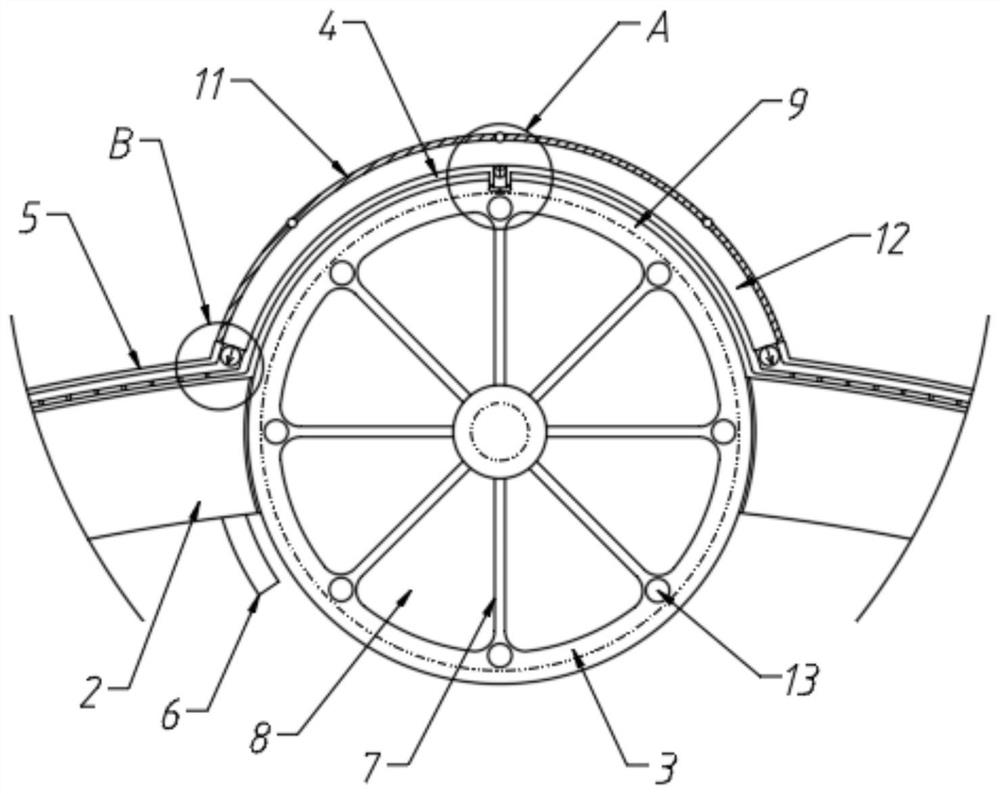

[0025] refer to Figure 1-5 , a fast heat dissipation enclosure for outdoor lasers, including:

[0026] The first housing 1, the interior of which is used to install laser components;

[0027] The second shell 2, the second shell 2 is fixedly arranged on the outside of the first shell 1, that is, the first shell 1 is inside the second shell 2, and the second shell 2 is provided with a plurality of rotating ports parallel to its axis;

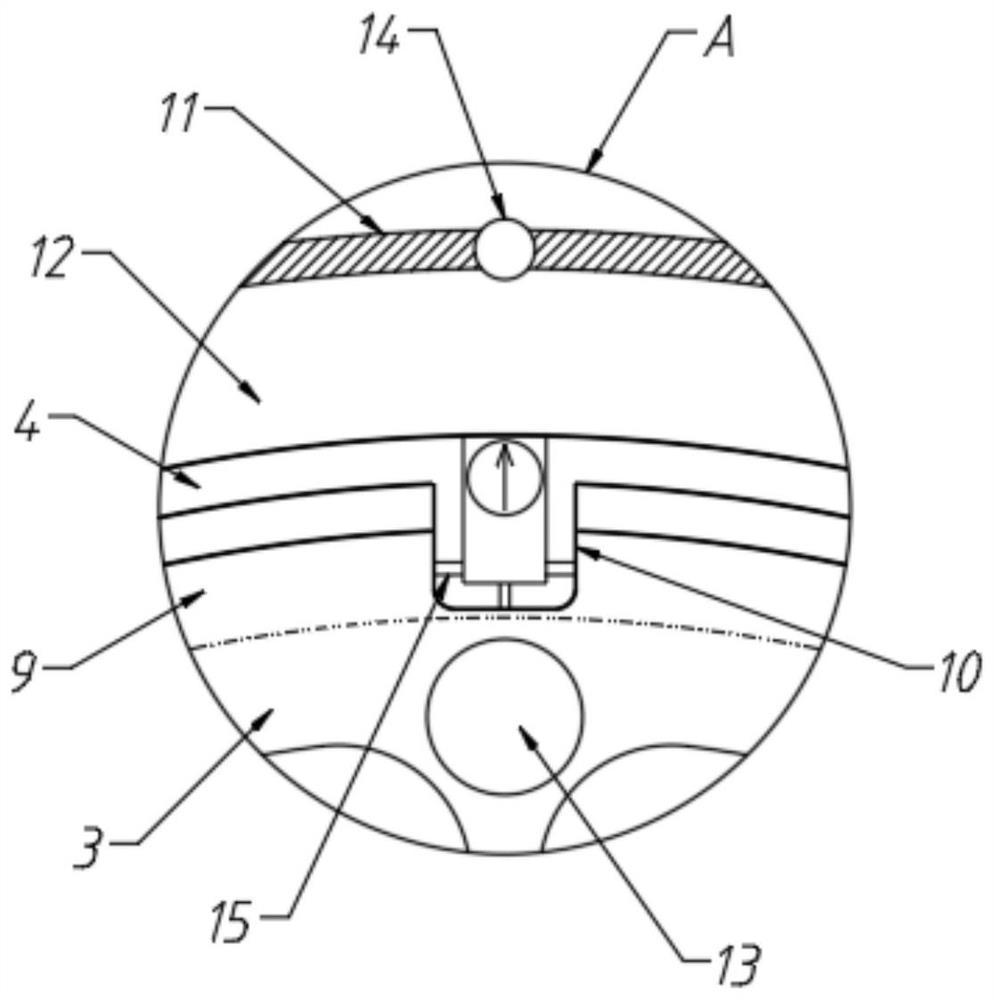

[0028] The rotating part is used to absorb heat and generate rotation. The rotating part includes a first magnet 6, a rotating cylinder 3 and a plurality of partition plates 7. The rotating cylinder 3 is arranged in the rotating port through the rotation of the rotating shaft, and the separating plates 7 are arranged on the rotating cylinder 3. Inside, the length and width respectively extend axially and radially along the rotating cylinder 3. The interior of the rotating cylinder 3 is divided into a plurality of fan-shaped and mutually indepen...

Embodiment 2

[0037] The difference between this embodiment and the first embodiment is that the elastic sheet 11 is made of rubber material, and the third magnet 14 is arranged on the elastic sheet 11, and a plurality of second magnets 13 are embedded in the wall of the rotating cylinder 3. The second magnets 13 are equally spaced along the circumferential direction of the rotating cylinder 3, and the distribution of magnetic poles between two adjacent second magnets 13 is opposite; specifically, during the rotation of the rotating cylinder 3, the third magnet 14 frame is subject to attraction and repulsion Force, and then cause the elastic sheet 11 to produce periodic fluctuations, and finally cause the gas flow in the suction chamber 12; compared with Embodiment 1, this solution can make the elastic sheet 11 produce stable vibration when the laser is running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com